XtremeRO Reverse Osmosis & Nanofiltration

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

Landfill leachate is produced by residual water and precipitation passing through degrading waste deposits. It presents unique challenges for water treatment. Depending on the age and type of landfill, leachate contains a mixture of organic and inorganic substances such as sulfates, nitrates, chlorides, ammonia, heavy metals, PFAS and other substances.

Flow rates and treatment goals can vary widely and impact treatment decisions. For example, a larger flow plant may benefit from multiple unit operations to optimize costs, while smaller flows could be treated with a single solution. Every case is different. We bring our leachate treatment experience to your benefit, helping you understand your options and costs.

Biological processes such as MBBR/MBR are widely used to remove organics and ammonia from landfill leachate. Ultrafiltration can remove total suspended solids. Neither remove salts that make up total dissolved solids (TDS)—our specialty. Options for TDS removal include:

Our solutions are compact, modular, and pre-packaged to minimize site installation costs. We partner with the best for biological treatment—if required—and your local contractors for integration. We can help you understand your options, costs, risks, and how to meet regulatory requirements including options for zero liquid discharge.

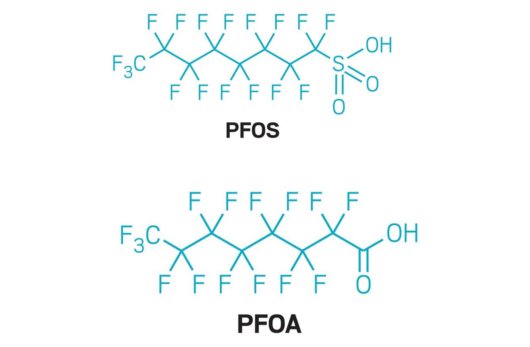

PFAS (perfluoroalkyls and polyfluoroalkyls) chemicals are widely used in consumer and industrial products and have become a serious issue in landfill leachate. These “forever chemicals” do not naturally degrade and are receiving increasing attention.

New advances in desalination technologies can help reduce PFAS treatment and disposal costs: ultra-high pressure reverse osmosis systems (UHP RO) such as XtremeRO, minimal liquid discharge (MLD) and zero liquid discharge (ZLD) solutions such as our SaltMaker family. Saltworks can help with PFAS problems, integrating solutions into existing or new wastewater processes.

Our SaltMaker MultiEffect evaporator crystallizer has been proven on multiple raw landfill leachates and leachate RO brines. You can read about its success in our case study. Our SaltMaker solution reduced landfill leachate volume, generating highly concentrated brine or solids for return to landfill. Brine concentrations in excess of 30% solids-by-mass (outside reverse osmosis range) were increased to over 60%. Our SaltMaker customers benefit from:

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

FlexEDR is a next-gen electrodialysis reversal (EDR) system for industrial wastewater desalination, solving scaling issues & boosting recovery.

The SaltMaker MultiEffect is an industrial evaporator crystallizer that reduces brine volume, even to zero liquid discharge (ZLD).

Saltworks Technologies Inc. (Saltworks) completed an end-to-end zero liquid discharge (ZLD) and zero air emission off-site pilot to treat concentrated reverse osmosis leachate brine from a municipal landfill in China.

PFAS chemicals are often referred to as “forever chemicals” since they do not naturally degrade. Saltworks’ solutions can treat PFAS in water.

Reverse osmosis (RO) is the best available technology to treat landfill leachate for surface discharge. Possible trace volatile organic compounds (VOCs) and ammonia emerging in the RO permeate can be removed with a polishing step to meet the highest discharge standards.

Digester wastewaters are by-products of biogas production in anaerobic digesters. They require treatment prior to disposal. To meet regulation compliance, treatment options range from minor interventions such as selective contaminant removal, to major interventions such as minimum and zero liquid discharge (MLD/ZLD).