SaltMaker MVR & MSF Evaporative Crystallizers

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

Saltworks » Applications » Brine Treatment and Volume Reduction

Our brine management experts help clients to understand their treatment and disposal options, including discharge regulations and economics for their process.

Brine management options may include treatment followed by disposal of minimized brine. Brine desalination treatment produces a more concentrated, lower-volume fluid or even just solids that are easier to transport or dispose of. Disposal involves discharging brine to sewers, surface water, injection wells, or sending it to environmental service providers for specialized handling.

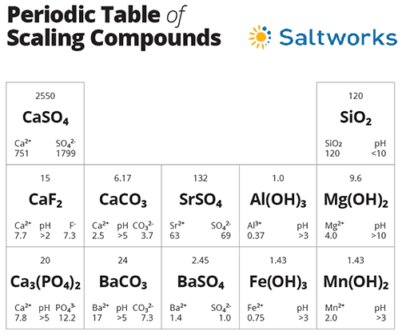

Water chemistry analysis is essential to effective and economic brine management. Factors such as salinity, scaling potential, the presence of any potential foulants, and metals or other contaminants are particularly important considerations for brine treatment projects.

Our team manages chemical analysis for clients, then performs early feasibility testing and develops a treatment solution that meets our clients’ regulatory requirements, maximizing plant performance and up-time, and minimizing total costs.

If you are currently using an evaporation pond of any kind, we know how challenging it is to manage its volume, and that expanding capacity is expensive.

Our expert team will study project data to find the most cost-effective solutions for unique projects, including finding innovative ways to reduce fluid volumes sent to a pond, optimizing existing treatment assets to boost freshwater recovery, selectively removing troublesome ions so that pond water can be reused, or treating more aggressively—up to minimal or zero liquid discharge.

Innovative solutions, such as combining different wastewater streams for desired chemical outcomes, or reusing waste-heat, can greatly lower project costs and we are accustomed to identifying such opportunities for our clients.

Increasing freshwater recovery from existing assets can very cost-effectively extract more freshwater, with a smaller volume of rejected brine being sent to a pond. We identify what the limits on recovery are and address them with cost-optimized chemical treatment and advanced controls to manage costs and protect assets.

Cost-effective brine treatment firstly requires maximizing recovery of lower-cost membrane systems such as reverse osmosis—before additional treatment or disposal.

We supply extreme recovery membrane brine concentrators supported by excellent chemical reactor and ultrafiltration systems.

The next step is comparing disposal options against thermal treatment, to decide whether to further concentrate brine or treat it down to solids.

If membrane recovery has been optimized and further brine volume reduction is needed, we also offer minimal and zero liquid discharge solutions. Our experts work with clients and design to prevent scale, simplify solids handling and disposal, and reduce the total cost of ownership.

We supply modular, fully packaged industrial evaporator-crystallizers for ultra-reliable thermal treatment, such as our SaltMaker product family. Contact us to get your brine management or volume reduction project started.

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

Reverse osmosis-based brine concentrators are reaching new performance levels not seen before. Saltworks is pleased to report that a substantial pilot plant is currently demonstrating 99% freshwater recovery on cooling tower blowdown (CTB).

RO recovery and RO brine concentration are limited by osmotic pressures or membrane scaling; both limits have been increased by new technologies. A series of techniques described here can be used to delay or mitigate scale, but in many cases only chemical softening truly removes risk.

Treating RO brine optimally begins with utilizing lower-cost membrane systems to minimize volume for downstream processing. Clients must then decide between the available thermal treatment options that allow for brine concentration or treating down to solids for disposal.

Before investing in an industrial evaporator for your water treatment applications, lower your risks by asking any vendor the following five questions that cover key topics such as brine disposal, scale prevention, and cost of ownership.