Heavy Metals Water Treatment

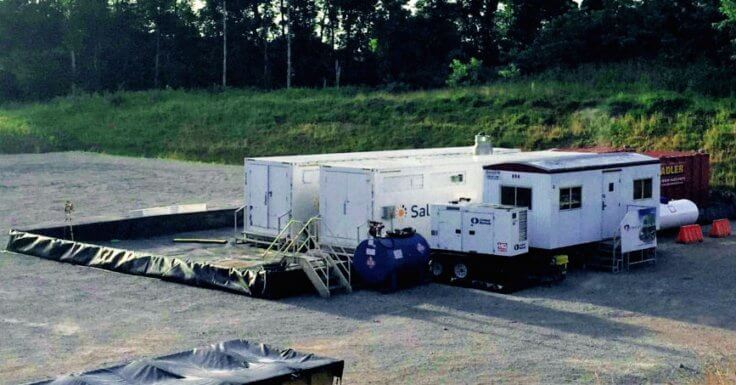

Heavy metals such as arsenic, cadmium, copper, lead, mercury, etc. can be critical components of many wastewaters and often require treatment. Conventional precipitation & coagulation (P&C) processes are well-practiced to treat heavy metals. Saltworks has modernized these processes to reduce footprint, maintenance, and operating costs.