In the latest episode of The Water Values podcast, host Dave McGimpsey interviews Saltworks CEO Ben Sparrow about zero liquid discharge (ZLD), the range of technologies involved in achieving ZLD and how Saltworks helps companies achieve their treatment goals.

With rising disposal costs and changing regulatory requirements, industries are looking for reliable solutions to treat challenging wastewater. McGimpsey and Sparrow explore the spectrum of water technologies that allow companies to treat a variety of different wastewaters and some of the applications where they offer the best economic fit. They also discuss the growing shift towards zero liquid discharge as a treatment target and the different ways companies can improve reuse of their wastewater, as well as the components it contains.

Listen to the podcast now on the Water Values website, or on the podcasting app of your choice.

About Saltworks

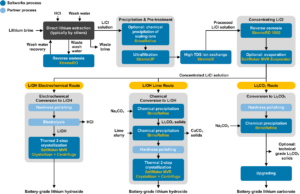

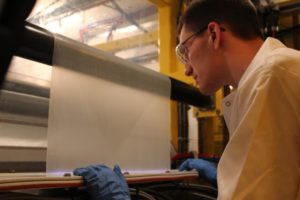

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Related Resources

ESG and Industrial Water: What Should Corporate Leaders Focus On?

Water plays a critical role in ESG performance for many companies. With growing concerns around pollution ands consumption of water and energy, investing in responsible water management technology can improve your ESG profile and reduce operational risks.

ZLD Without Evaporation: Saltworks Achieves First ZLD With a Membrane Crystallizer

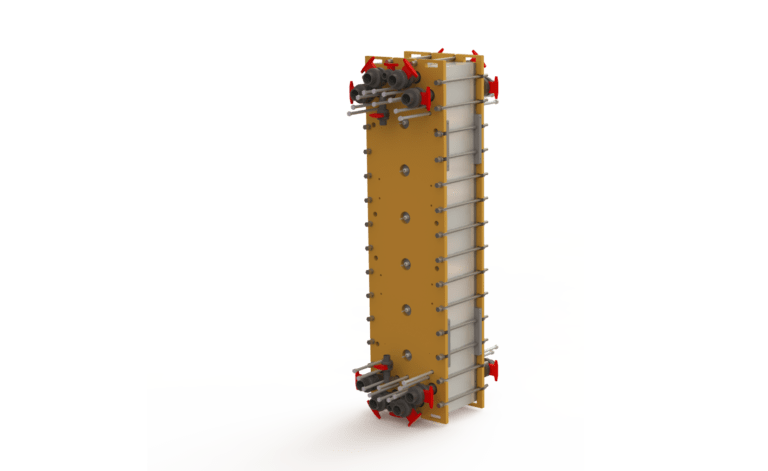

Saltworks’ engineers achieve ZLD without conventional energy-intensive boiling through a novel membrane-chiller and UHP-RO hybrid plant for a mining client.

SaltMaker Evaporators & Crystallizers

Our SaltMaker modular evaporators and crystallizers turn almost any wastewater into clean water, minimal liquid discharge (MLD) brines or zero liquid discharge (ZLD) solids.

How to Manage Brine Disposal & Treatment

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).