XtremeRO & OARO—Membrane Brine Concentrators

High-pressure reverse osmosis (RO) and osmotically assisted reverse osmosis (OARO)

Next-generation high-pressure reverse osmosis (RO) and osmotically assisted reverse osmosis (OARO) concentrate and recover freshwater from high-strength brines. Achieve industry-leading recovery and reliability with a membrane-based system and reduce the size and cost of downstream thermal treatment.

Reverse Osmosis Membrane Concentrators

Reverse Osmosis (RO) is the world’s dominant desalination technology. It uses pressurized, semi-permeable membranes to remove dissolved salts from water. RO is typically the most economical solution for initial brine treatment and should be considered first for most industrial desalination applications.

UHP-RO and OARO

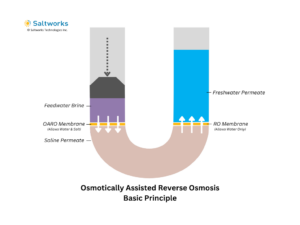

Ultra-high pressure (UHP-RO) and osmotically assisted RO (OARO) are newer variants of RO. By using special ultra-high pressure membranes, UHP-RO concentrates brine up to 130,000 mg/L total dissolved solids (TDS).

OARO concentrates brine up to 200,000 mg/L TDS by using cascading RO circuits. These technologies enable membrane-based treatment of more concentrated brines, provide greater freshwater recovery and brine volume reduction, and can reduce the capacity required for downstream thermal treatment.

XtremeRO

Saltworks’ XtremeRO is available in four versions for a wide range of industrial treatment applications:

- XtremeRO 600 operates at 600 psi (41 bar) and concentrates brine up to 40,000 mg/L TDS

- XtremeRO 1200: 1,200 psi (80 bar) and up to 80,000 mg/L TDS

- XtremeRO 1800 (UHP-RO): 1,800 psi (120 bar) and up to 130,000 mg/L TDS

- OARO: up to 200,000 mg/L TDS

Minimal Liquid Discharge (MLD) Systems

Saltworks packages XtremeRO into modular, digitized systems for minimal liquid discharge (MLD) applications. Our MLD systems are further enhanced with our BrineRefine and XtremeUF technologies.

These remove scaling ions, such as silica and calcium, to minimize fouling risk, enhance membrane longevity, and allow XtremeRO to reach osmotic pressure limits.

Our MLD systems also include intelligent diagnosis and self-cleaning. The result is a complete, fully automated membrane-based brine concentrator with industry-leading reliability and lowest total cost.

Start Your XtremeRO & OARO Project

Saltworks specializes in designing and delivering complete XtremeRO brine concentrator systems for industrial desalination, chemical recovery, or lithium refining applications.

We provide initial technical consultation to understand treatment options, residuals management, integration with existing treatment processes, and total cost optimization.

Take advantage of our process design expertise, comprehensive pilot testing program, full-scale design and delivery, and remote operations and support.

Contact our experts to get started on your project today.