BrineRefine—Modular Chemical Reactor

Automated, fully packaged, flexible physical-chemical reactor system

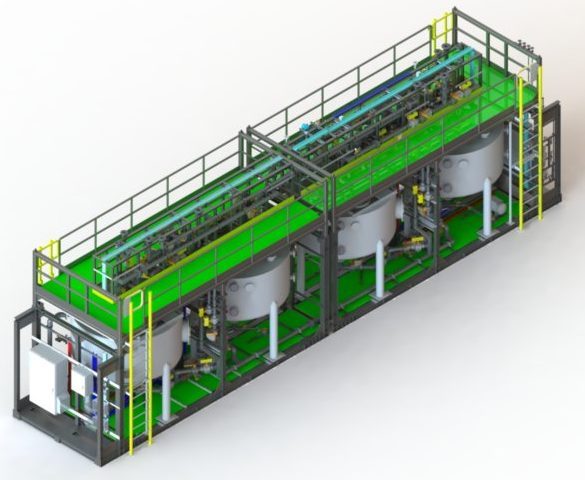

BrineRefine is a smart, compact, and modular continuous stirred tank reactor (CSTR) that executes chemical reactions efficiently. BrineRefine combined with our other systems maximizes reverse osmosis recovery, remove contaminants-of-concern, and produces valued precipitates such as lithium carbonate.

BrineRefine: Chemical Reactor Re-Invented

Whether in an industrial wastewater treatment chain or refining and producing battery-grade lithium products, BrineRefine optimizes whole processes with excellent controls, economics, intelligent automation, and reliability. It excels in addressing variability in water chemistry.

BrineRefine is designed with modularity, automation, and simple solids management at its heart. A continuous stirred-tank reactor (CSTR) system, BrineRefine consists of modular, factory-built ISO skids with built-in redundancy and expansion capability.

Application Examples

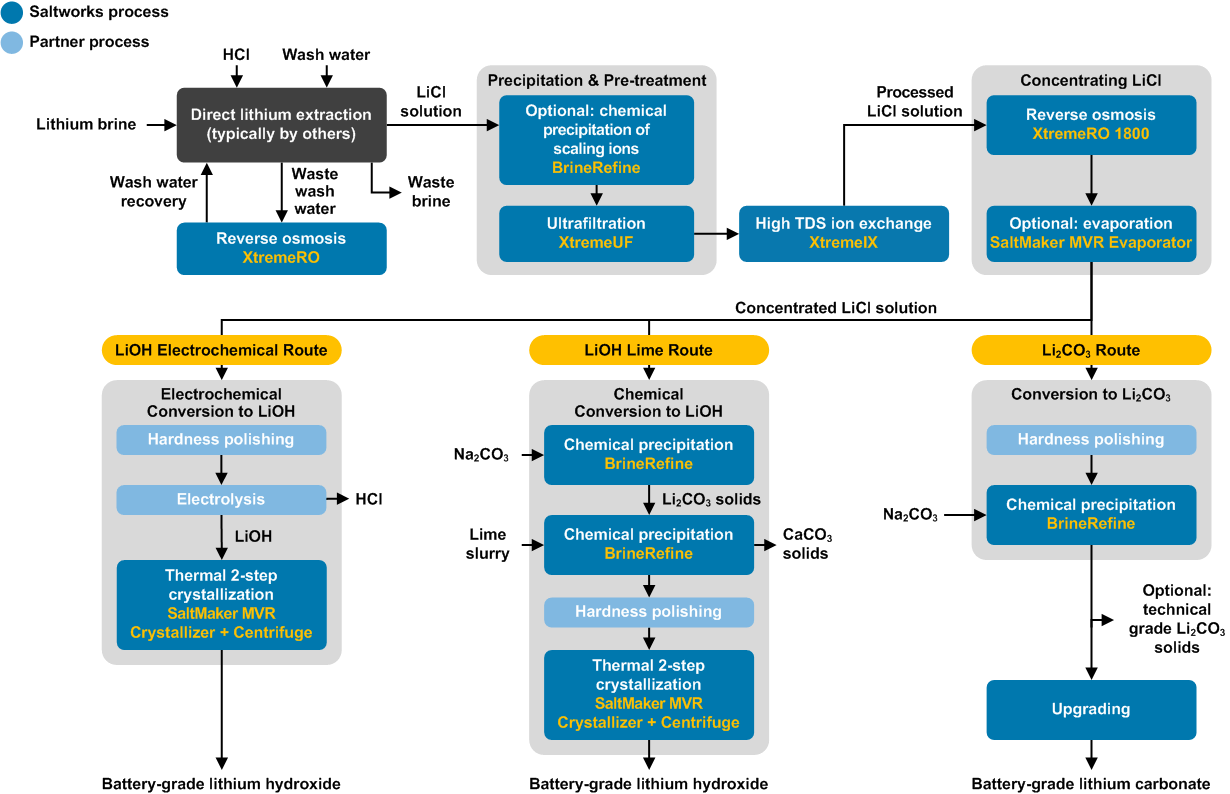

BrineRefine in Lithium Production and Refining

BrineRefine removes impurities in lithium brines by precipitating metals, magnesium, or calcium. BrineRefine also produces lithium carbonate (Li2CO3) and refines it to >99.9% purity. Our lithium infographic gives more information on the processing of lithium brines as produced by direct lithium extraction (DLE).

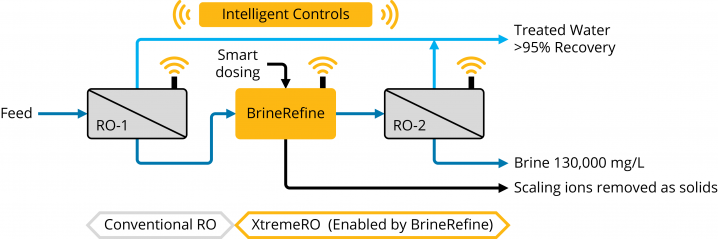

Maximizing Membrane Freshwater Recovery With Chemical Softening

BrineRefine was originally developed to remove scaling ions in a precise modular package without the need for coagulation, flocculation, and large clarifiers. When partnered with XtremeUF, the combination minimizes footprint while protecting downstream RO membrane health. The package communicates with downstream assets such as reverse osmosis systems—optimizing performance and freshwater recovery and managing scaling risk.

Integrate with XtremeRO to achieve 50% less brine than conventional solutions, with concentrations up to 130,000 mg/L TDS.

Cost-Effectively Targeting Contaminants of Concern

BrineRefine can target and remove specific contaminants, such as cyanide, sulfates, or phosphates, avoiding the need for more complex and expensive treatment. Selectively removing one or two constituents of concern to meet a specific treatment or reuse goal is often the most cost-efficient approach, rather than treating an entire stream to freshwater standards.

Fenton's Reaction for Oxidation of Organics

Fenton’s reaction is a reliable advanced oxidation method used for the destruction of complex organics. The reaction involves the addition of Fe2+ and an oxidant and pH control, to produce hydroxyl radicals, which in turn oxidize organics. Saltworks’ BrineRefine is well suited to performing Fenton’s reaction, offering precision control and flexibility and advanced automation bundled in a high-quality modular package. Options are available for efficient, integrated sludge management.

Customizable CSTR Chemical Reactor Applications

As a modular and highly automated CSTR system, BrineRefine has broad applicability to many chemical processes. For unique projects with atypical challenges or opportunities, BrineRefine is customizable and adaptable. We have engineered BrineRefine to be a modular flexible platform. Our team is ready to take on your challenge, with pilot plants available to prove performance.

BrineRefine removes impurities in lithium brines by precipitating metals, magnesium, or calcium. BrineRefine also produces lithium carbonate (Li2CO3) and refines it to >99.9% purity. Our lithium infographic gives more information on the processing of lithium brines as produced by direct lithium extraction (DLE).

BrineRefine was originally developed to remove scaling ions in a precise modular package without the need for coagulation, flocculation, and large clarifiers. When partnered with XtremeUF, the combination minimizes footprint while protecting downstream RO membrane health. The package communicates with downstream assets such as reverse osmosis systems—optimizing performance and freshwater recovery and managing scaling risk.

Integrate with XtremeRO to achieve 50% less brine than conventional solutions, with concentrations up to 130,000 mg/L TDS.

BrineRefine can target and remove specific contaminants, such as cyanide, sulfates, or phosphates, avoiding the need for more complex and expensive treatment. Selectively removing one or two constituents of concern to meet a specific treatment or reuse goal is often the most cost-efficient approach, rather than treating an entire stream to freshwater standards.

As a modular and highly automated CSTR system, BrineRefine has broad applicability to many chemical processes. For unique projects with atypical challenges or opportunities, BrineRefine is customizable and adaptable. We have engineered BrineRefine to be a modular flexible platform. Our team is ready to take on your challenge, with pilot plants available to prove performance.

Decrease Your Chemical Costs

BrineRefine keeps treatment or production chains on specification. It avoids expensive and imprecise manual dosing by relying on automated controls, drastically reducing the need for operator intervention, maintenance, and monitoring. It incorporates a one-step, simple solids management system.

Reach out to our experts to discover how BrineRefine fits into your project.