SaltMaker ChilledCrys Crystallizer

ChilledCrys is a novel and highly competitive alternative to expensive evaporators for zero liquid discharge of specific chemistries.

Saltworks » Applications » Sulfate Wastewater Removal

Sulfates are widespread in many industries such as mining, oil & gas, fertilizer production, pulp & paper, and more. Although not generally very dangerous to humans, high sulfate levels are often regulated to protect the environment.

Sulfate challenges vary significantly. For example, one of the most important considerations in deciding how to manage a sulfate-laden wastewater flow is the total dissolved solids (TDS). Once our team completes a chemistry review, most of our clients’ sulfate removal needs can be addressed with one of a high- or low-TDS approach. We provide cost-effective solutions for both.

High TDS sulfate-laden waters (TDS~80,000–200,000 mg/L) often predominantly contain sodium sulfate: SO42- ~60,000–120,000 mg/L. To treat them, you can take advantage of two unique properties of sodium sulfate:

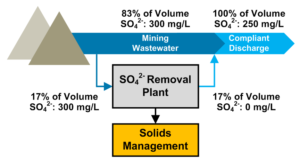

Low TDS waters (1,500–5,000 mg/L) can still often be saturated in calcium sulfate: SO4 ~1,800 mg/L. If sulfate and metals are your only treatment concern, then you may be able to avoid brine management costs. Sulfates can sometimes be targeted for removal, without needing to treat all of the dissolved mass contained within an entire flow, keeping costs low.To optimize your sulfate management costs, you should consider:

Our offerings for sulfate solutions comprise one or more of the following industrialized product lines:

The details of your project matter. For example, for seasonal sulfate challenges, chemical precipitation treatment may keep capital investment low, with the operating costs of chemicals being present only for a part of the year. On the other hand, if the challenge is year-round, and there is a low-cost disposal option for a sulfate-rich brine, sulfate-rejecting membrane solutions may make more sense.

We can help you to make informed choices with economic analysis provided for all of the possible options for your sulfate challenges.

Contact us to learn more about our solutions and options and how sulfates may be most economically treated using industrial water treatment technologies.

ChilledCrys is a novel and highly competitive alternative to expensive evaporators for zero liquid discharge of specific chemistries.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

Saltworks is thrilled to help clients lower installation and operational costs and future-proof their plants. This was recently demonstrated through delivery of a modular BrineRefine and XtremeUF system that enables the targeting of ions of value or concern with substantially reduced waste.

There are many sulfate treatments available, with different advantages and disadvantages. Factors for consideration include capital and operational costs, solid vs. liquid brine reject for disposal, if the need is seasonal or year-round, and suitability for adverse operating conditions.

Real-time measurement provides prompt feedback for controls. A real-time sensor can help to optimize your process, reduce risk, and minimize operational and maintenance demand. Saltworks has developed a new real-time sensor—that is simple and robust—to operate in the high-TDS range.

Saltworks completed an off-site FlexEDR Selective pilot test to treat flue gas desulfurization (FGD) wastewater from a coal fired power plant in China. The objective was to reduce chlorides such that the FGD wastewater could be internally recycled and final treatment costs reduced notably.