Semiconductors and Electronics

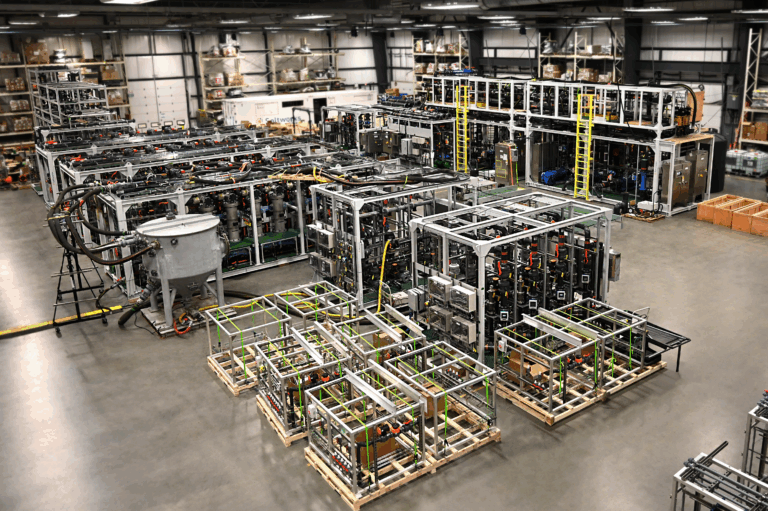

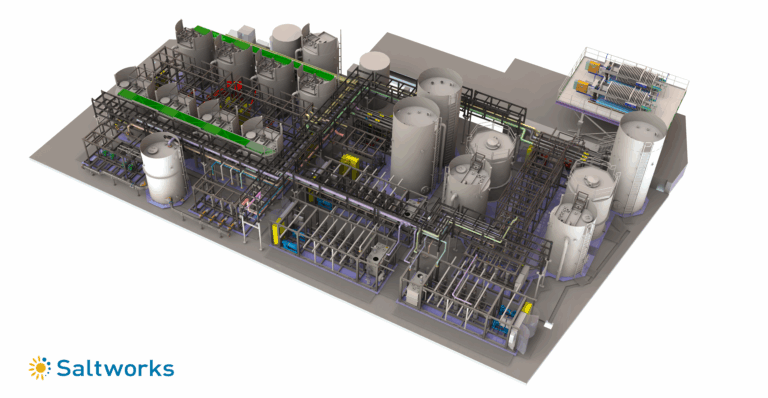

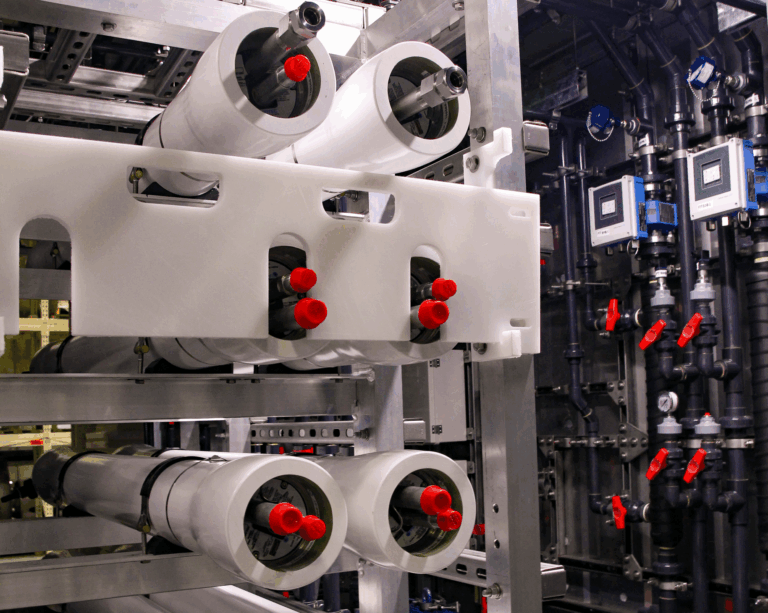

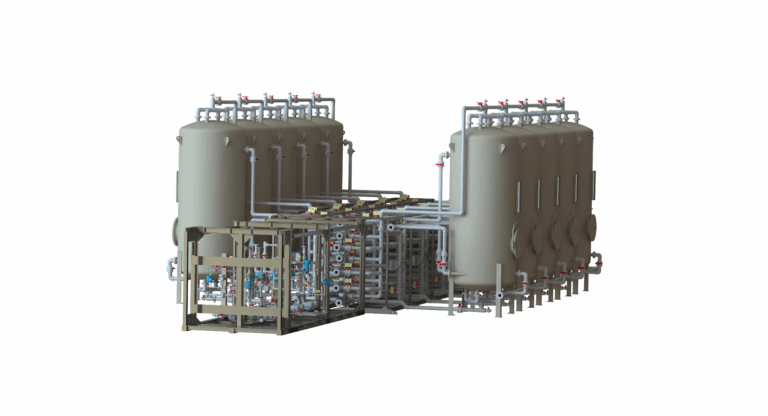

The manufacturing of microelectronics generates unique wastewaters. Saltworks can help you to manage wastewater flows from microelectronics production, targeting fluoride, ammonia, metals, and ions, reducing brine waste, and allowing water reuse.