SaltMaker AirBreather

Air emissions-safe, 1-effect, open thermal evaporator crystallizer

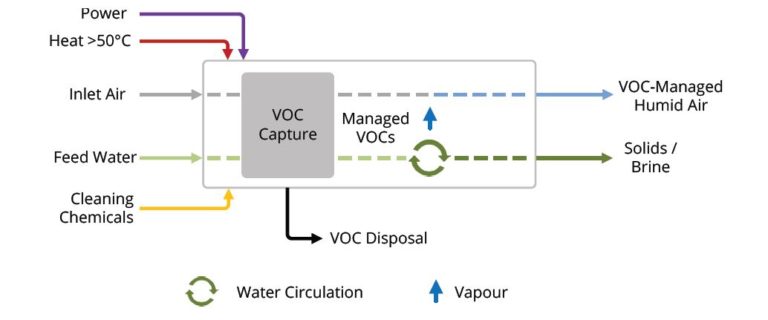

SaltMaker AirBreather with patented low-emission technology is the first open-to-atmosphere evaporator-crystallizer to provide safe, regulation-compliant operation for wastewaters with volatile compounds.

Open-to-Air Evaporators

Conventional open-to-atmosphere evaporators release water vapor, which may include volatile compounds such as organics and ammonia.

When evaluating or operating an open-to-atmosphere evaporator it is important to understand local air emission regulations and the impacts of vapor plume and volatiles.

SaltMaker AirBreather

SaltMaker AirBreather is the first open-to-atmosphere evaporator-crystallizer designed from the ground up to mitigate air emission risks.

Saltworks uses patented processes to ensure zero contact of wastewater to the atmosphere. AirBreather is guaranteed to meet emissions targets, including for volatile organic compounds, methanol and particulates.

It is the first and only technology to receive a full-scale permit in a challenging jurisdiction where six prior open-to-atmosphere pilots failed to meet VOC and/or particulate emission requirements.

Optional Configuration & Waste Heat

AirBreather’s standard configuration is clean water vapor release with no freshwater returned. An alternate configuration with freshwater return is also available (i.e. for reuse or surface discharge).

The technology operates more efficiently at lower temperatures compared to many traditional evaporation technologies, allowing efficient utilization of low-grade waste heat, as low as 50°C (120°F).

This capability renders AirBreather ideal when both brine volume reduction and process cooling are required.

Modularity & Rapid Deployment

AirBreather is constructed with durable, non-stick, non-corroding wetted parts and uses a modular design with built-in redundancy.

This makes the technology suitable for harsh, demanding environments.

The modular design uses pre-fabricated ISO-container-sized blocks for cost-effective transport and rapid site installation. Modules slide in and out for easy inspection and maintenance and are easily added to expand capacity.

Additional Advantages

In safe-emission configuration, AirBreather emits only a small fog patch visible in cold ambient temperatures, unlike the tall vapor plume of conventional evaporators.

The technology uses intelligent automation to maximize performance, including capacity control, self-cleaning, and self-diagnosis.

AirBreather also incorporates simple solids management: a single-step process discharges solids in bags or bins for easy handling – no chemical pre-treatment or softening sludge required.

Contact us today to get started on your project.