XtremeUF Ceramic Ultrafiltration

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Saltworks » Applications » Pharmaceutical Industry Wastewater Treatment

Here are some examples of how Saltworks and its products can help with your pharmaceutical project:

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

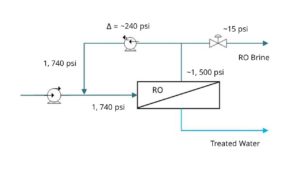

New ultra-high pressure reverse osmosis technology for minimal liquid discharge (MLD) can reduce brine management costs by three times relative to evaporators. Modernized chemical softening technology is available to prevent scaling and enable recovery up to the osmotic pressure limit at 1,200 or 1,740 psi.

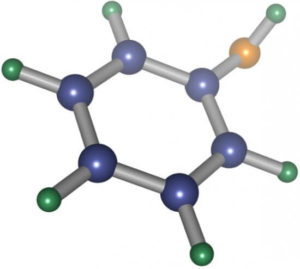

Excessive phenolic compounds are harmful to human health and the environment. Chlorophenols, by-products of chlorinating phenol-containing water, are carcinogens. A treatment system needs to be chosen and engineered carefully, with consideration of specific wastewater chemistry, operating conditions, and economics.

Digester wastewaters are by-products of biogas production in anaerobic digesters. They require treatment prior to disposal. To meet regulation compliance, treatment options range from minor interventions such as selective contaminant removal, to major interventions such as minimum and zero liquid discharge (MLD/ZLD).

Saltworks is thrilled to announce the first full-scale order for an industrial Ultra-High Pressure Reverse Osmosis (UHP RO) system with Nitto high performing HYDRANAUTICSTM PRO-XP1 spiral wound membranes rated to 1,800 psi (124 bar).