SaltMaker MVR & MSF Evaporative Crystallizers

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

Saltworks » Applications » Zero Liquid Discharge & Minimal Liquid Discharge

Before investing in equipment, let us provide an engineering study to help you reduce total costs and improve reliability.

We offer solutions that can lower your cost through selective ion removal:

A rapid upfront analysis can inform your decision pathway, such that you invest your valuable time in the most viable options.

The most cost-effective way to achieve MLD or ZLD is to avoid it altogether. If your wastewater challenge is limited to one or two constituents of concern, we may be able to target and remove them.

Using a variety of treatment methods, robust real-time sensors, and our expertise, we can avoid the need for more complex and expensive treatment.

The second most cost-effective pathway to MLD or ZLD is through minimizing brine volumes with optimized membrane systems.

We safely push reverse osmosis (RO) assets to their osmotic potential by measuring and removing scaling ions in real-time. Improve the performance of existing or added RO assets by:

Our XtremeRO product can reach concentrations as high as 130,000 mg/L TDS, as much as twice the concentration achieved by conventional RO systems.

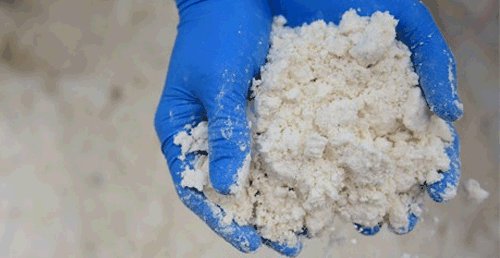

Concentrate your brine down to minimal liquid or even solid waste with our SaltMaker family.

All are engineered as a complete MLD/ZLD package for corrosion and scale-free operation, automated self-cleaning, low-cost site installation, and ease of service.

We offer evaporators and crystallizers in several classes:

We provide comprehensive solutions so you can treat the toughest wastewaters to minimal or zero liquid discharge. We can target ions, treat oily and organic wastewater, and help you achieve economic ZLD.

Contact our experts to determine which solutions work best for your wastewater treatment needs.

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.