SaltMaker MVR & MSF Evaporative Crystallizers

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

Saltworks » Applications » Industrial Wastewater Treatment

The first step in managing your industrial wastewater is to define your goals. Do you need to meet discharge requirements, minimize off-site disposal costs, reduce freshwater withdrawal, or achieve reuse targets? Do you need to target problematic contaminants such as metals and ions, achieve minimal or zero liquid discharge, or recover valuable by-products from your wastewater?

Next, you need to know what’s in your water, figure out what constituents you need to treat, and set project targets. After that comes understanding your options—both the technologies and the economics. Industrial wastewaters can be complex, with variable compositions that make treatment more challenging. Saltworks can help with the entire process—from project discovery and options analysis, to pilot scale testing and all the way to full-scale plant delivery.

Some of the industrial wastewater components we frequently encounter and address include:

At the early stages of a project, it is important to know the concentrations of components like these in your industrial wastewater, how they vary, and the overall wastewater flow rate.

Delivering the right wastewater treatment process is not just about treating the waste stream and its components. Often the most reliable and economic solution will combine treatment, recycling, and disposal. Other project concerns may include:

When fresh water is scarce or costly, treating and re-using wastewater can provide a cost-effective water supply while improving sustainability outcomes, and therefore ESG metrics.

Harvesting valuable reagents, metals, nutrients, and more from spent wastewater can also add a lot of value for some industries.

Wastewater reuse considerations start with chemistry, permits, and an applicable technology review. It may be that only one or two constituents of concern prevent re-use and that by targeting their removal, massive volumes of water can be recycled. In other cases, you may require extremely clean fresh water with minimized brine residual by-products.

Saltworks’ water experts help with water chemistry, project details, and overall objectives. We develop comprehensive options analyses that consider available technologies, treatment and disposal economics, and regulatory requirements.

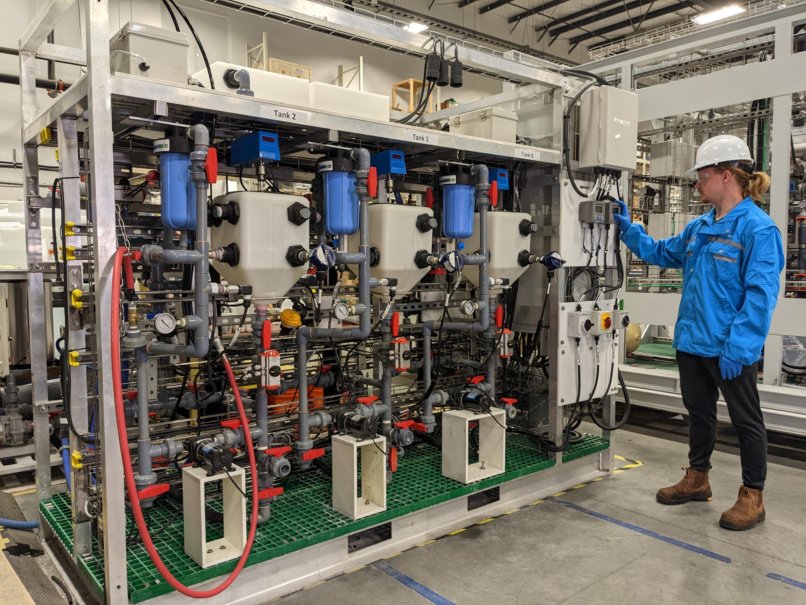

Our proprietary solutions include advanced chemical, thermal, and membrane systems that work alongside novel sensor technologies and intelligent controls. We offer an even wider range of technologies through our partners, enabling us to provide a wastewater treatment solution optimized for your specific project.

We scale up in whatever way suits you best, starting with desktop studies and mobile pilot systems that quickly and cost-effectively prove performance, either at the project site or our facility. Our full-scale plants are designed, engineered, and manufactured at our own facility, ensuring responsiveness, cost-optimization, and quality assurance from project start to testing, and through to delivery and commissioning. We can also perform in-place upgrades to modernize, automate, or expand your existing wastewater treatment facilities. To learn more about how we treat the toughest waters, see our wastewater treatment articles.

To investigate your project’s treatment options, contact our expert industrial wastewater team.

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

Water plays a critical role in ESG performance for many companies. With growing concerns around pollution ands consumption of water and energy, investing in responsible water management technology can improve your ESG profile and reduce operational risks.

Saltworks’ engineers achieve ZLD without conventional energy-intensive boiling through a novel membrane-chiller and UHP-RO hybrid plant for a mining client.

Saltworks is thrilled to announce the first full-scale order for an industrial Ultra-High Pressure Reverse Osmosis (UHP RO) system with Nitto high performing HYDRANAUTICSTM PRO-XP1 spiral wound membranes rated to 1,800 psi (124 bar).

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).