XtremeUF Ceramic Ultrafiltration

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Saltworks » Applications » Pulp & Paper Wastewater Treatment

Water is an essential ingredient to the pulp and paper industries. Wastewater from pulp and paper processes may face regulatory scrutiny due to risks to aquatic life.

Wastewater concerns may include:

Reverse osmosis (RO) concentrates waste streams for disposal and recovers fresh water for processing. We can help you get the most out of RO with a suite of products that maximize performance, cost-effectiveness, and longevity:

Saltworks’ experts can help you to understand your options, including treatment, discharge regulations, and economics.

To decide on an appropriate and cost-effective treatment process, it is critical to know the wastewater chemistry in detail and understand the treatment goals and capacity needs.

Saltworks can review water chemistry and specific project requirements so that a treatment process is chosen that balances simplicity, cost-effectiveness, and reliability. Contact us for project reviews, water testing, pilots, and more.

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

This article introduces a new type of ceramic membrane system and explains how it opens the application range. An example of treatment of oil and grease in produced water is provided.

Excessive phenolic compounds are harmful to human health and the environment. Chlorophenols, by-products of chlorinating phenol-containing water, are carcinogens. A treatment system needs to be chosen and engineered carefully, with consideration of specific wastewater chemistry, operating conditions, and economics.

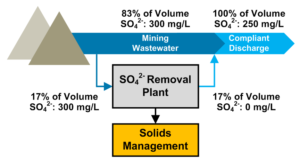

There are many sulfate treatments available, with different advantages and disadvantages. Factors for consideration include capital and operational costs, solid vs. liquid brine reject for disposal, if the need is seasonal or year-round, and suitability for adverse operating conditions.

Saltworks’ engineers achieve ZLD without conventional energy-intensive boiling through a novel membrane-chiller and UHP-RO hybrid plant for a mining client.