XtremeUF Ceramic Ultrafiltration

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Saltworks » Applications » Cooling Tower Blowdown

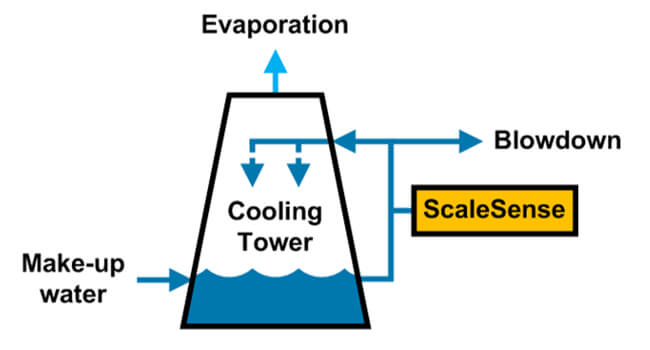

Cooling towers are widely used in industrial processes to eject heat. As cooling tower water is cycled and evaporated, total dissolved solids (TDS) and scaling ions concentrate. This accumulation results in the need to periodically ‘blow down’ the cooling tower water and replace it with freshwater. This cooling tower blowdown (CTB) wastewater may require treatment.

More cycling before blowdown, or treating and re-using blowdown water, means lower water consumption and lower net waste volumes generated. Optimizing cooling towers may involve one or more of the following:

The next step in improving cooling tower performance is to selectively remove troublesome ions, reducing scaling risk and hence reducing blowdown and make-up volumes.

Remove scaling ions with BrineRefine: our automated chemical softening system can selectively remove many scaling species such as calcium, sulfate, and silica, allowing you to run your tower at higher cycles as a result. BrineRefine is compact and all solids can be extracted as a solid filter cake for ease of disposal.

Treat chlorides and scaling ions with FlexEDR Selective: remove scaling ions or chlorides with an electrodialysis reversal (EDR) kidney loop.

Treatment of blowdown wastewater allows for the recovery of freshwater and reduces the volume requiring disposal.

Treat blowdown with XtremeRO: our next-generation reverse osmosis systems treat CTB. When combined with BrineRefine, up to 99% freshwater can be recovered, producing a very low-volume brine. Successive steps in recovery add cost. An economic optimum exists for each site, which we can help you to work out.

Achieve ZLD with SaltMaker: our family of advanced evaporator crystallizers turn low-volume brine into solids to achieve zero liquid discharge. Combine cooling and brine concentration into a single step with SaltMaker AirBreather. The AirBreather is a low-temperature, open-to-atmosphere evaporator. If a client requires a combination of cooling (~60 °C) and brine concentration, AirBreather can complete both simultaneously.

An accurate, real-time measurement of scaling ions means that real scaling risk—rather than assumed risk—can be known. For scaling ion-limited towers, this ensures that blow downs are neither too early, nor too late, allowing safe reductions in freshwater and anti-scalant treatments while preserving the health of components such as the heat exchanger.

Optimizing performance with ScaleSense: Saltworks’ has developed new real-time sensor technologies that can measure the concentrations of scaling ions, even at high TDS. A robust, real-time sensor is the lowest cost, first solution.

Contact us to learn more about how your cooling tower performance can be enhanced and for blowdown treatment options.

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

A full-scale, waste heat-driven, Saltworks evaporator has been delivered to an electric vehicle (EV) battery plant. The SaltMaker AirBreather evaporator will treat a highly saline wastewater stream to reduce its volume, reducing the client’s need to truck wastewater offsite.

Saltworks delivers reliable solutions for data center cooling that maximize uptime and energy efficiency while helping meet water sustainability goals. Our modular, low footprint systems can optimize cooling cycles, reduce scaling, and minimize wastewater disposal volumes.

Reverse osmosis-based brine concentrators are reaching new performance levels not seen before. Saltworks is pleased to report that a substantial pilot plant is currently demonstrating 99% freshwater recovery on cooling tower blowdown (CTB).

Cooling towers are used by industrial plants to reject waste heat to atmosphere. A portion of the cooling water is blown down after a number of cycles of concentration, before the ions and metals reach their scaling limits. This blowdown requires management.