SaltMaker MVR & MSF Evaporative Crystallizers

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

Saltworks » Applications » Medical Device Manufacturing Wastewaters

As medical devices become more complex and diverse, so does their manufacturing. Water is essential for rinsing and other processes and controlling contamination is critical.

Manufacturers may need to expand production without exceeding discharge limits or water consumption thresholds, or may need to reduce waste disposal costs.

Saltworks can help you treat wastewater components-of-concern such as solvents, ammonia, formic acid, halides, metals, oils & grease, chemical oxygen demand (COD), total suspended solids (TSS), and total dissolved solids (TDS).

Saltworks’ product line can treat for a wide range of organic and inorganic contaminants, selectively target metals and ions for removal, and reduce discharge volumes. We can also develop a custom process for your specific application. Some examples of how we can help:

Whether your goal is meeting discharge limits, lowering raw water consumption, or reducing waste disposal costs, Saltworks can provide a cost-effective and reliable solution to manage your unique medical device wastewater.

We will review your water chemistry and specific project requirements, provide a comprehensive options analysis, and develop a treatment process for your specific application. Contact us for project reviews, pilot testing, and full-scale systems.

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

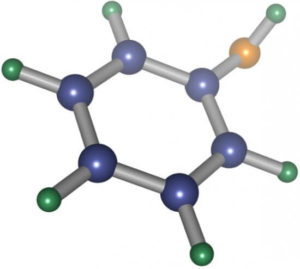

Excessive phenolic compounds are harmful to human health and the environment. Chlorophenols, by-products of chlorinating phenol-containing water, are carcinogens. A treatment system needs to be chosen and engineered carefully, with consideration of specific wastewater chemistry, operating conditions, and economics.

The manufacturing of microelectronics generates unique wastewaters. Saltworks can help you to manage wastewater flows from microelectronics production, targeting fluoride, ammonia, metals, and ions, reducing brine waste, and allowing water reuse.

No two pharmaceutical wastewaters are the same. Saltworks can help you to treat complex wastewaters from this critical industry with certainty. We implement solutions that target organics, metals, and ions for removal, reduce brine waste, and allow water reuse.