XtremeUF Ceramic Ultrafiltration

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Disposal wells are an important means to safely dispose of many of the most hazardous fluids deep underground. Disposal wells may face challenges such as:

Saltworks can help with both of these challenges.

When two different wastewaters are allowed to commingle, a water-insoluble solid can be precipitated. This risks plugging the well. One example is the mixing of sulfate- and barium-rich waters, which react to form barium sulfate.

A real-time sensor can protect a disposal well by screening the wastewaters for high content of incompatible ions. Controls using our ScaleSense sensor can divert an incompatible flow into a separate stream, which we can inexpensively treat before disposal, for example with a product like BrineRefine.

Volume reduction options can help to achieve the best use of disposal well pressure and volume capacity. Our membrane products—such as XtremeRO—can produce a more concentrated, lower volume fluid. Our SaltMaker evaporators can reduce volume further, with options to suit your energy, chemistry, and capacity needs.

Saltworks’ volume reduction experts can help you to understand your treatment and disposal options, including discharge regulations and economics. Contact us to get started.

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

ScaleSense is an automated, real-time sensor that measures calcium, barium, sulfate, and silica in high TDS brines.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).

Real-time measurement provides prompt feedback for controls. A real-time sensor can help to optimize your process, reduce risk, and minimize operational and maintenance demand. Saltworks has developed a new real-time sensor—that is simple and robust—to operate in the high-TDS range.

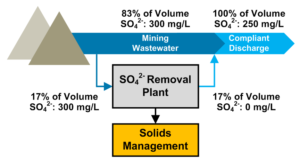

There are many sulfate treatments available, with different advantages and disadvantages. Factors for consideration include capital and operational costs, solid vs. liquid brine reject for disposal, if the need is seasonal or year-round, and suitability for adverse operating conditions.

Disposal wells are an established method for disposing of hazardous fluids by injecting them deep underground. Commingling (mixing) incompatible fluids in a disposal well may inadvertently cause solids to precipitate, which risks plugging the well. Plugging is disruptive and costly to fix, but operators can prevent it with advanced sensors, controls, and targeted wastewater treatment.