XtremeUF Ceramic Ultrafiltration

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Saltworks » Applications » Brackish Water Desalination

Brackish water has more dissolved solids than freshwater, but generally less than seawater. Besides sodium chloride, other prominent dissolved solids include manganese, iron, sodium sulfate/bicarbonate, calcium sulfate/bicarbonate, and occasionally naturally occurring radioactive material (e.g. radium). The compositions can vary extensively and may even change with time.

Brackish groundwater can be extracted from suitable locations, often below freshwater aquifers. It is increasingly used as an alternative to freshwater. For many purposes brackish water is desalinated to lower its salinity and/or total dissolved solids (TDS). Advanced membrane treatment technologies that are used to do this include reverse osmosis (RO) and ultrafiltration (UF). However, since many brackish water resources are inland, consideration of brine minimization and management for these plants is essential.

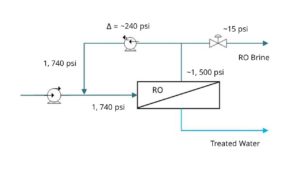

Conventional ultrafiltration (UF) and brackish water reverse osmosis (BWRO) plants are low cost and widely available. However, they also operate with conventional recoveries, generating substantial brine volumes that must be managed.

More advanced reverse osmosis processes are emerging, pushing recoveries up by 5–10% through unique hydraulic designs, aggressive anti-scalants, and process controls that help maintain membrane throughput.

Saltworks can perform or support advanced brackish desalination projects, taking you a few steps further. We can help you to optimize the entire process for lowest cost of ownership, including: consideration of risk management, redundancy, and up-time.

We can measure and remove scaling ions from your upstream BWRO to enable additional RO stages that reach the maximum attainable osmotic pressure limits, boost freshwater recovery, and limit brine waste.

Contact us to learn more about your brackish water desalination strategy can be improved with advanced technologies.

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

Saltworks delivers reliable solutions for data center cooling that maximize uptime and energy efficiency while helping meet water sustainability goals. Our modular, low footprint systems can optimize cooling cycles, reduce scaling, and minimize wastewater disposal volumes.

Saltworks is thrilled to announce the first full-scale order for an industrial Ultra-High Pressure Reverse Osmosis (UHP RO) system with Nitto high performing HYDRANAUTICSTM PRO-XP1 spiral wound membranes rated to 1,800 psi (124 bar).

Saltworks is pleased to announce that recent advancements in reverse osmosis technology are now commercially available. Reduce conventional RO brine volumes by 50%, achieving brine concentrations of 130,000 to 150,000 mg/L TDS with spiral wound RO membranes.

New ultra-high pressure reverse osmosis technology for minimal liquid discharge (MLD) can reduce brine management costs by three times relative to evaporators. Modernized chemical softening technology is available to prevent scaling and enable recovery up to the osmotic pressure limit at 1,200 or 1,740 psi.