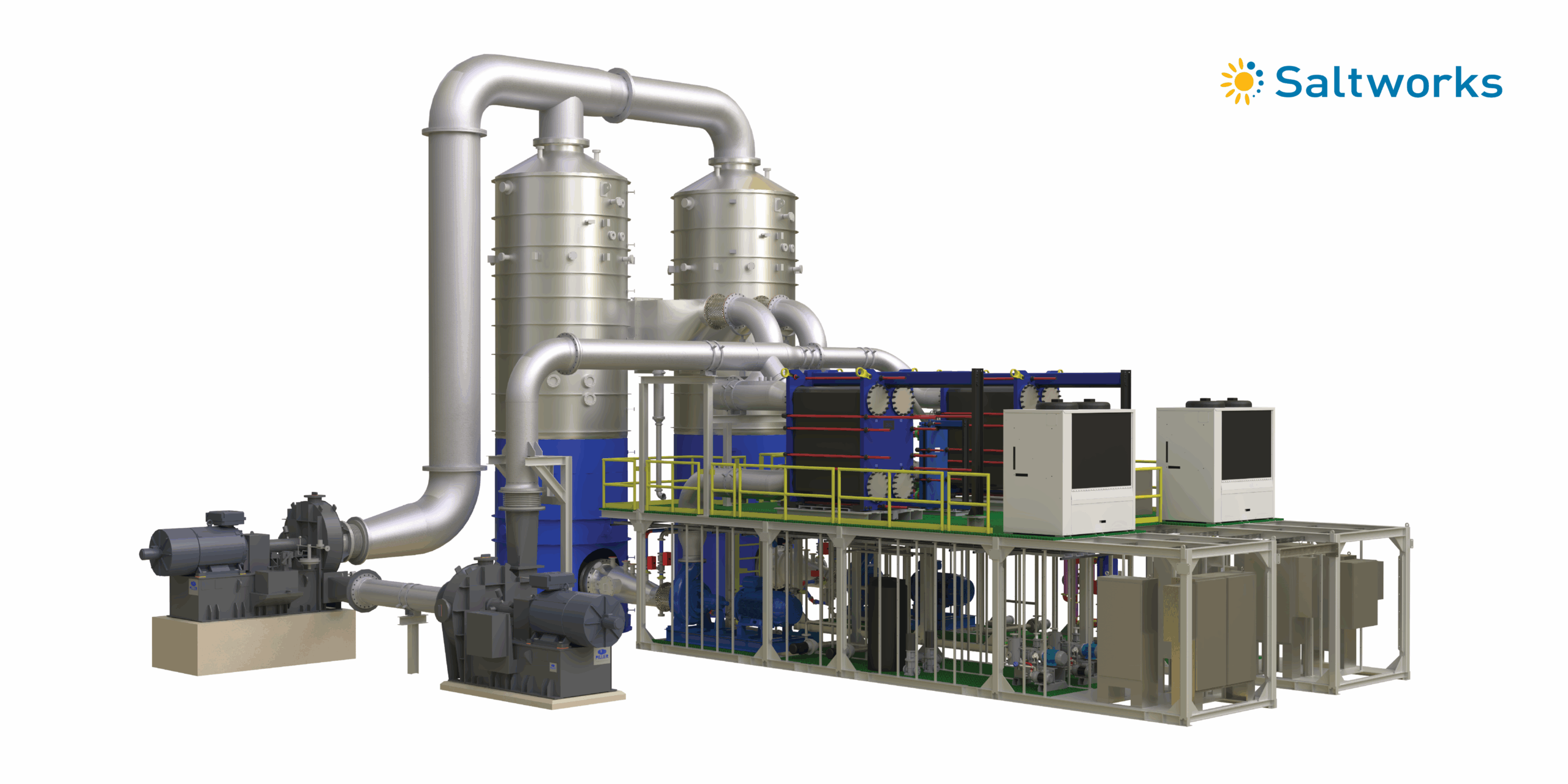

Saltworks Releases FusionRO: UHP RO/NF Membrane Brine Concentrator

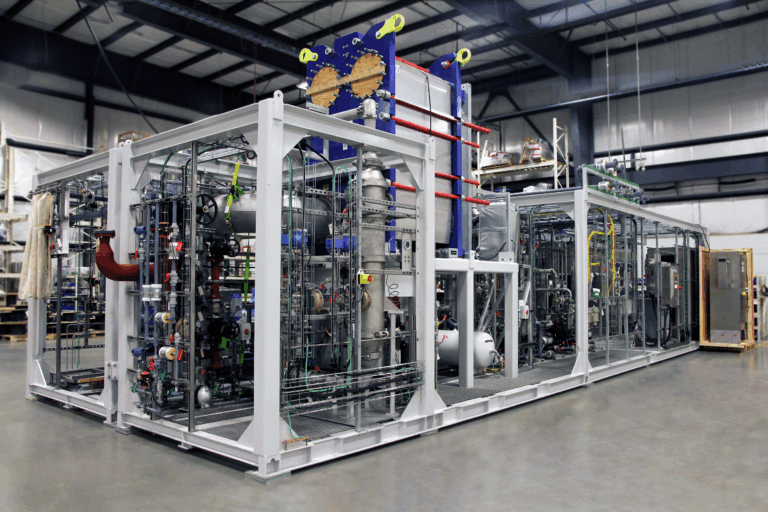

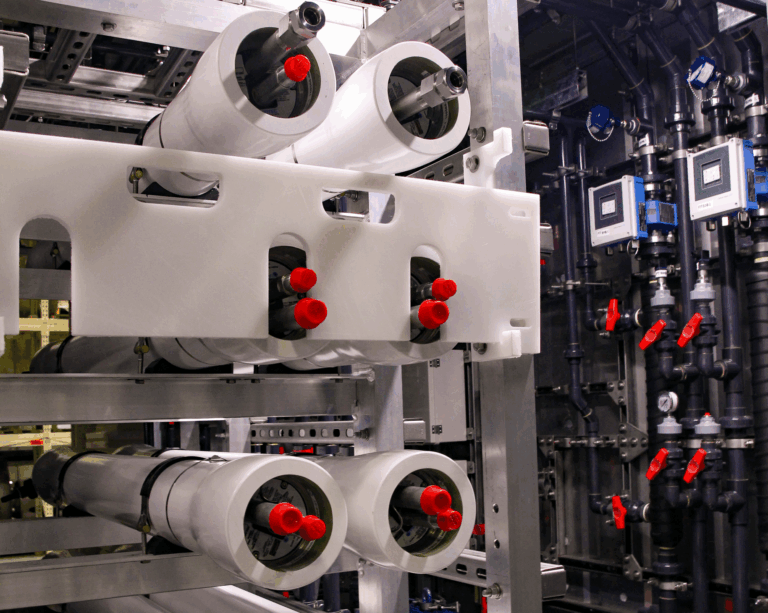

Saltworks launches FusionRO, a hybrid UHP RO/NF membrane brine concentrator that achieves >220,000 mg/L TDS. Built on UHP RO and NF, FusionRO offers a lower-cost, scalable, and smaller footprint solution, minimizing the cost and size of downstream thermal treatment.