SelectNF - Tailored Nanofiltration

Selective Nanofiltration Delivered with Precision Controls in Robust, Modular Packages

Unlock selective ion manipulation opportunities with Saltworks' SelectNF—tailored nanofiltration (NF) solutions for industrial applications.

Choosing Nanofiltration

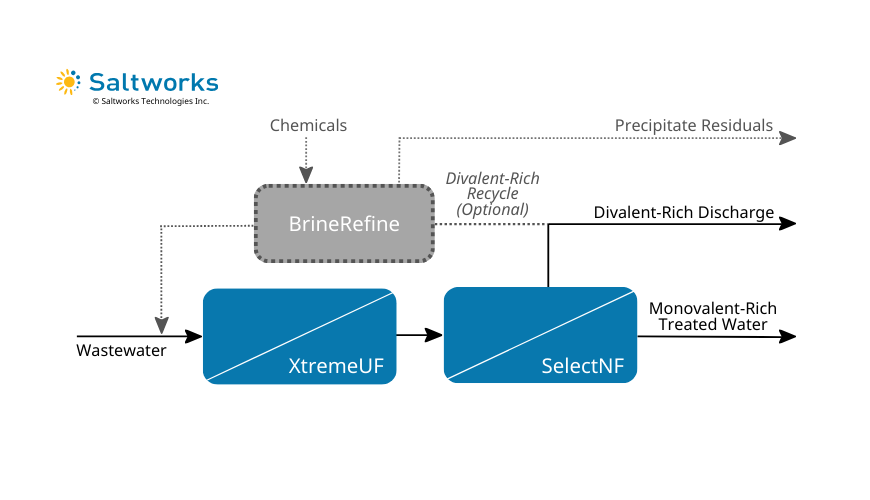

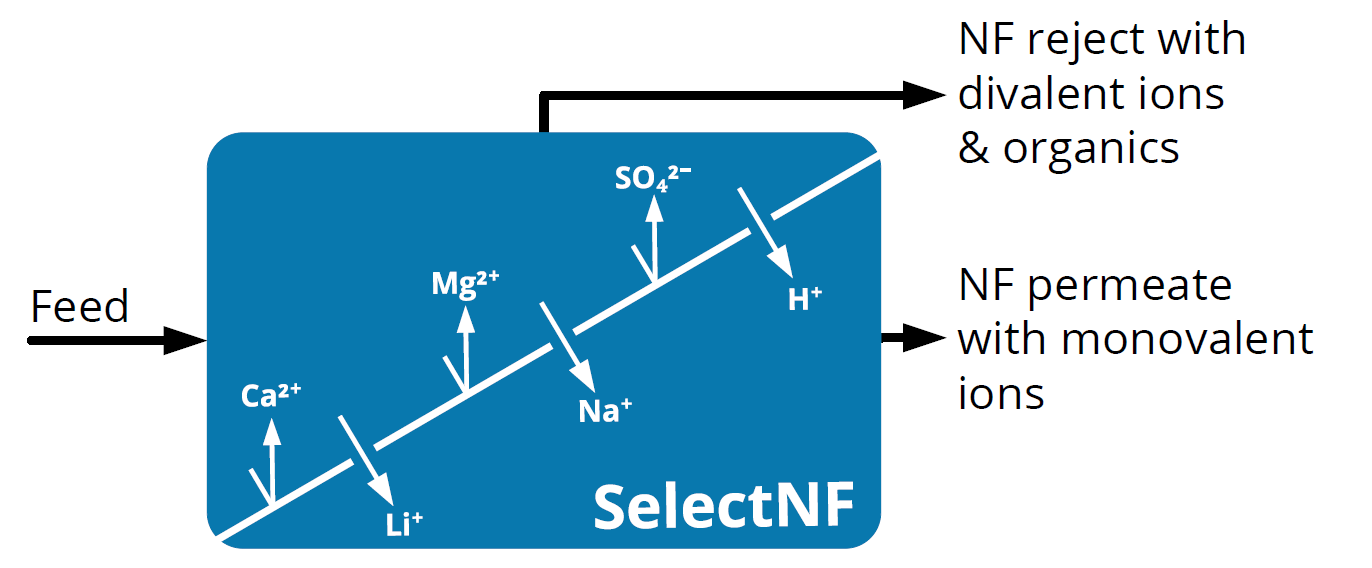

Our nanofiltration systems employ best-in-class NF membranes in unique process configurations to tailor monovalent/multivalent ion separation.

Standardized RO membranes reject 99.9% of all ions, producing permeate largely void of salts. In contrast, NF membranes produce a saline permeate, largely consisting of monovalent ions (e.g., LiCl), while rejecting most multivalent impurities (e.g., SO42-, Ca2+, silica, and large or charged organics).

NF membranes do not provide a perfect mono-multivalent separation but do enable unique process opportunities.

Despite the differences in outputs, RO and NF membranes are mechanically interchangeable; they are compatible with the same pumps and vessels, and switching between them will not affect the balance of a processing plant.

Various commercial, quality-assured NF membranes exist and their performance varies depending on operating conditions including pH and pressure. Saltworks works with leading NF membrane providers to deliver pilots and full-scale systems that serve industrial selective ion separation needs.

SelectNF – Specialized Applications

Saltworks’ SelectNF is designed for advanced nanofiltration applications where industry data and models fall short.

For NF success, a deep technical understanding of membrane types, process conditions, and appropriate recycling and management options is necessary.

By leveraging our experienced membrane scientists, global NF membrane providers and our extensive pilot and unique applications database, Saltworks is uniquely positioned to help clients achieve their NF processing goals.

All SelectNF applications are carefully assessed and tested by our expertly staffed pilot center to calibrate process models and ensure full-scale success.

Uni-RO Standardized Platform

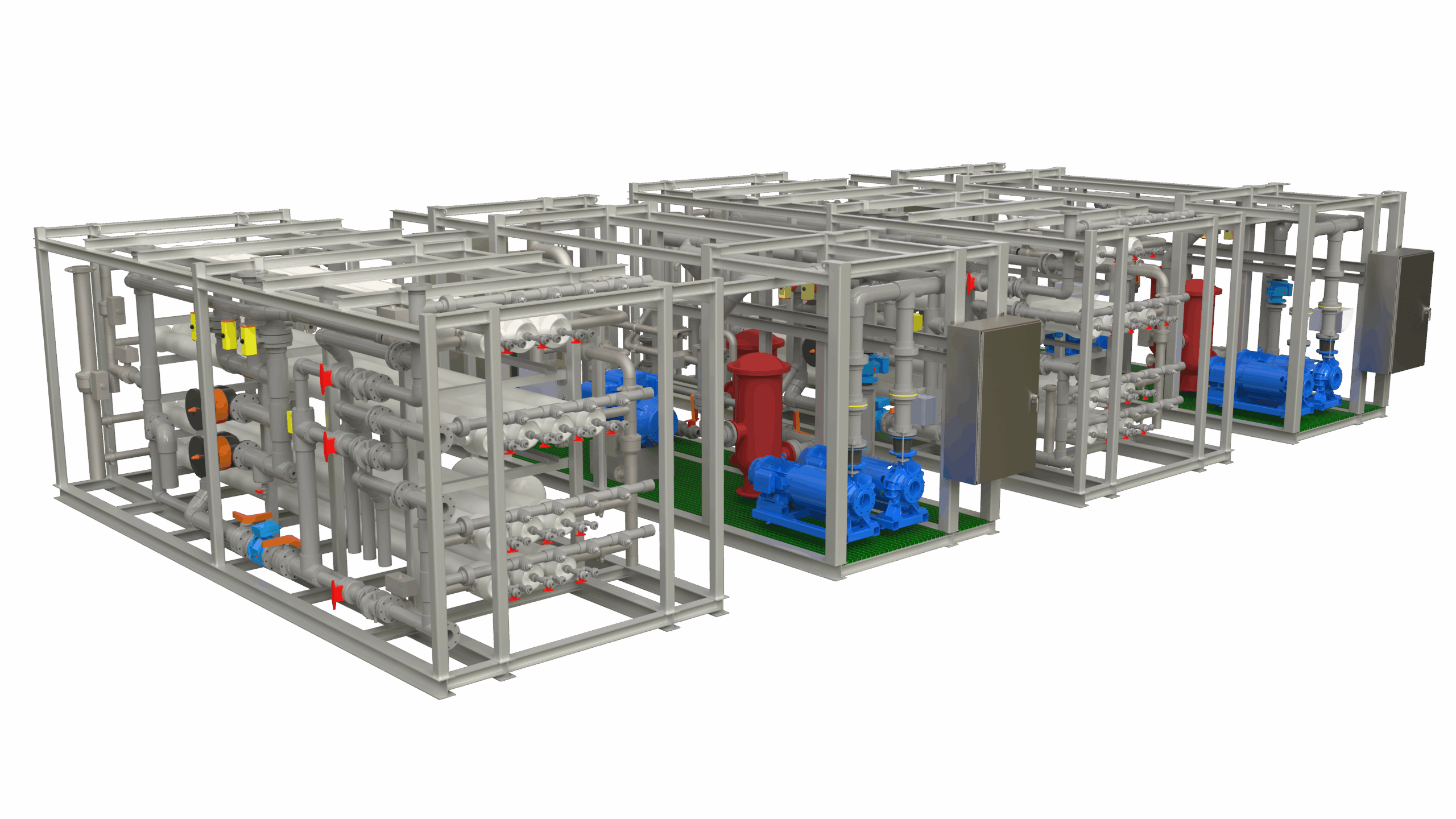

Saltworks’ membrane brine concentrators are built on our Uni-RO platform—a modular, repeatable, and standardized design shared across XtremeRO, FusionRO, and SelectNF. The core skid, frame, and components are the same, with only pressure ratings and membrane types varying between systems.

Uni-RO is a fungible shared architecture that simplifies scaled deployment while delivering economies of reliability, operation and maintenance. All Uni-RO based skids are factory assembled and tested for lowest field installation cost.

Project Success With Saltworks

SelectNF offers our clients the unique opportunity to tailor their impurity removal process. But, like all treatment processes, it has limitations. NF applications are bespoke and require careful consideration of fouling, scaling, relative rejection rates, ion balancing, process parameters and brine recycling options.

Once your project is pre-qualified for SelectNF, our experts will run proprietary process models to predict your project’s performance and cost your plant. From there, we can rapidly pilot and scale your novel processing solution leveraging our Uni-RO platform.

Contact us today to explore how NF can optimize your brine.