Zero Liquid Discharge & Minimal Liquid Discharge

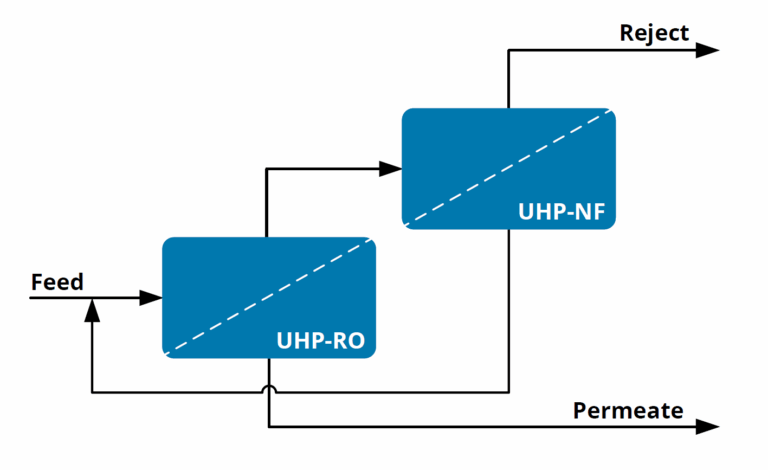

Our innovative brine management solutions maximize freshwater recovery and minimize waste products, reducing disposal costs. We optimize costs with the correct blend of membrane and evaporator crystallizer solutions.