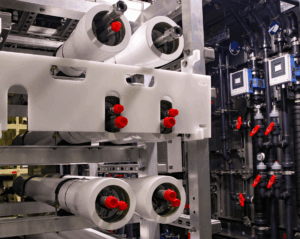

XtremeUF Ceramic & Polymeric Ultrafiltration

XtremeUF ceramic and polymeric ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Saltworks Technologies (“Saltworks”) has successfully deployed two FusionRO plants to international clients, marking another milestone in advancing ultra-high membrane brine concentration (MBC) technologies.

FusionRO, a form of low-salinity rejection reverse osmosis (LSRRO), achieves a brine concentration of sodium chloride exceeding 220,000 mg/L at 50% lower capital expenditure (CapEx) and operating expenditure (OpEx) than evaporators.

One plant was sold to a dominant lithium refiner and is concentrating lithium before conversion at a lower cost and energy than evaporators. The second plant was shipped to an industrial site to treat and reuse water while producing a minimal liquid discharge (MLD) brine. Both modular plants were rapidly installed and are operating as expected.

FusionRO hybridizes ultra-high-pressure reverse osmosis (UHP-RO) with UHP nanofiltration to concentrate brines 175% higher than conventional seawater RO.

Unlike lower-pressure RO systems, FusionRO requires half the number of high-pressure stages owing to its ultra-high pressure cascading loop design. The system features intelligent membrane monitoring, protection, and preservation controls to maintain membrane health, delivering significant energy and cost savings compared to evaporators on suitable fluids.

All Saltworks’ full-scale and pilot solutions are modular, factory-built, and fully commissioned before shipping. Our plug-and-play design reduces installation time, cost, and complexity in the field compared to conventional stick-built options.

Contact our expert engineers today to explore how Saltworks’ FusionRO can support your brine concentration goals.

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

XtremeUF ceramic and polymeric ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Our innovative brine management solutions maximize freshwater recovery and minimize waste products, reducing disposal costs. We optimize costs with the correct blend of membrane and evaporator crystallizer solutions.

Saltworks launches FusionRO, a hybrid UHP RO/NF membrane brine concentrator that achieves >220,000 mg/L TDS. Built on UHP RO and NF, FusionRO offers a lower-cost, scalable, and smaller footprint solution, minimizing the cost and size of downstream thermal treatment.

Our XtremeRO and FusionRO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.