Lithium Extraction and Refining

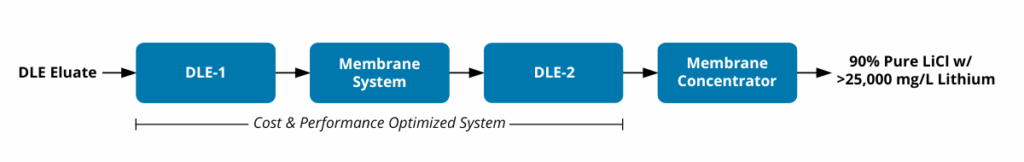

Saltworks brings water mining expertise and advanced desalination technologies to our lithium clients, offering solutions for concentrating, refining, and converting low-grade lithium sources to battery-grade product. We offer higher purity and lower energy processing technology, that boosts yield, removes unit operations, and reduces cost.