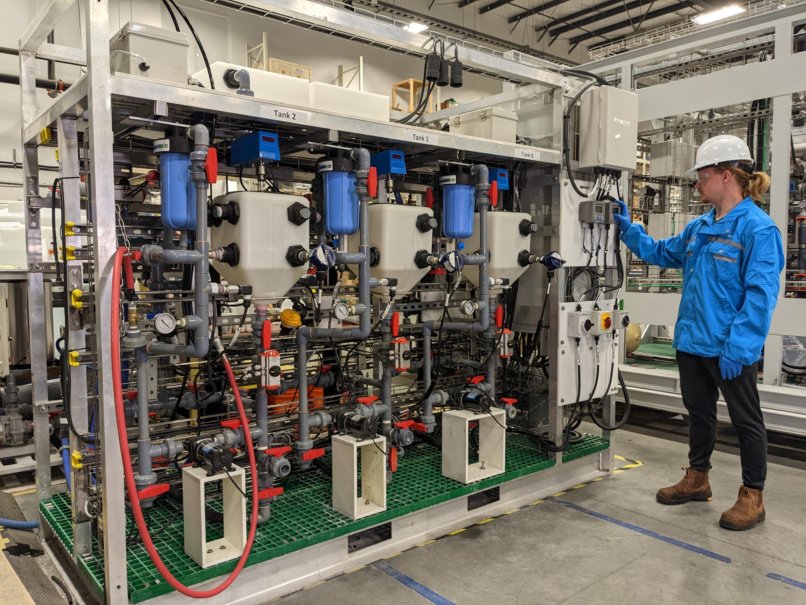

BrineRefine Chemical Reactor

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Saltworks is thrilled to help clients lower installation costs, reduce operational costs, and future-proof their plants. This was recently demonstrated through the delivery of a modular ‘plug and play’ digitized BrineRefine and XtremeUF system to a client in the Middle East. Integrated in a compact and fully automated plant, BrineRefine and XtremeUF enable Saltworks’ industrial clients to target ions of value or concern with substantially reduced waste.

BrineRefine continuous stirred tank reactor (CSTR) modules are modernized chemical reaction systems with a higher degree of precision and control. They produce battery-grade lithium chemicals or selectively remove ions of concern such as metals, silica, calcium, sulfates, fluorides, and more.

The delivered plant operates at a capacity of 200 GPM (1,100 m3/day) and precipitates a key ion of interest. The XtremeUF ceramic ultrafiltration unit polishes the BrineRefine output to reject sub-micron sized precipitants and is configurable with membranes of different pore sizes. This ensures complete treatment while also making the plant’s output flow ready for downstream membrane processing.

“This plant represents a major step forward for project delivery in a supply- and labor- constrained market,” said Saltworks’ VP, Technology & Projects, Derek Mandel. “The precision and intelligent controls are helping clients reduce chemical consumption, improve product quality, reduce waste generated, increase up-time, and better utilize their skilled labor force.”

Saltworks offers a broad range of modular, intelligently controlled solutions to recover valuable chemicals and treat industrial wastewaters. Different modules can be combined according to the customer’s needs, as with the integrated BrineRefine and XtremeUF units. Each modular skid neatly houses the required supporting equipment, including electrical and controls.

The plant delivered for this project is a prime example of one that progressed through Saltworks’ industry-leading pilot and testing programs—recently expanded to include our dedicated Lithium Test Centre. Saltworks’ clients have access to fully automated pilot plants—which represent the operational capabilities of full-scale plants—to trial chemistry and optimize performance. With pilot results in-hand, Saltworks’ skilled team then custom designs and builds the full-scale plants in-house, with tightly controlled supply chain and quality assurance to ensure smooth project progression.

Saltworks’ engineering expertise, pilot programs, modular intelligent plants, and extensive testing and commissioning at its production facility, reduce project installation cost, timelines, and risk. Contact us for a detailed review of your project needs.

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

New modular, intelligent, and automated chemical precipitation with a ceramic membrane filtration system eliminates the challenges of chemical overdosing and large footprint requirements.

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

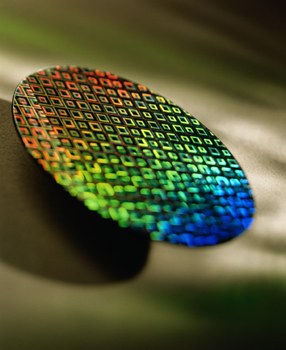

Saltworks delivered a full-scale, compact and automated XtremeUF ultrafiltration system to an advanced materials manufacturing plant in the US.