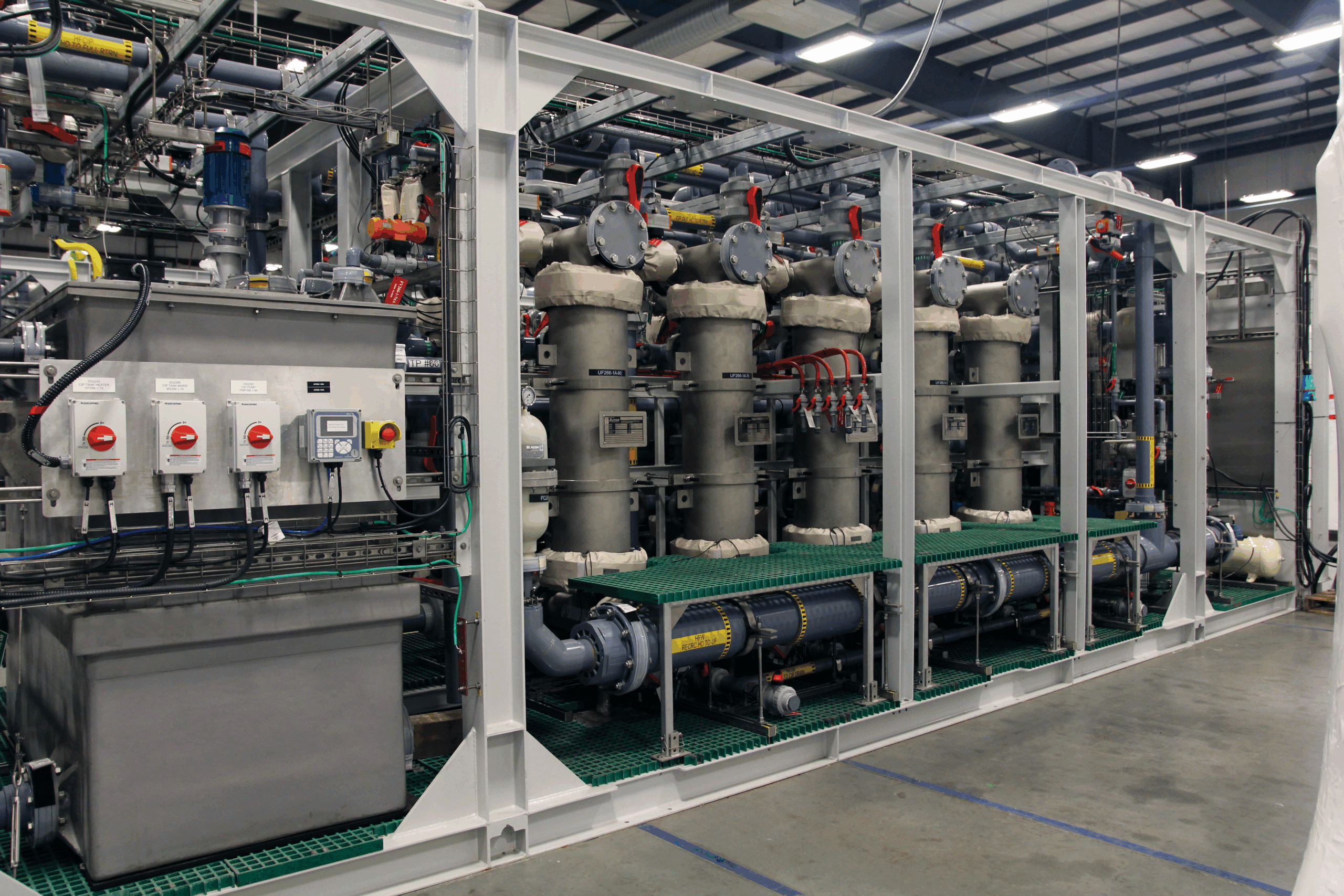

XtremeUF Ceramic & Polymeric Ultrafiltration

XtremeUF ceramic and polymeric ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Saltworks » Applications » Mining Wastewater Treatment

Treat Mine Impacted Waters or Recover Resources of Value

Mining waters are diverse in composition, often high in volume, and can vary seasonally. Compounding these challenges, mining locations are often remote. Saltworks’ advanced solutions are engineered for reliable and economic use across the mining industry, including:

Mine water is pretreated or filtered as needed and then passed through reverse osmosis (RO) to reject chlorides and other ions. RO brine volumes can be dialed to match water balance and brine storage needs or minimized through ultra-high recovery solutions such as FusionRO. Output: RO permeate ready for remineralization and RO brine matched to site needs.

Mine water is prefiltered via XtremeUF ultrafiltration, then treated with SelectNF nanofiltration to reject divalent ions (e.g., sulfates) and dissolved organics while allowing monovalent ions to pass. BrineRefine may be added for divalent ion precipitation, if needed.

Output: treated water with less divalent ions and reduced scaling risk (partial TDS reduction, not full).

BrineRefine CSTR applies targeted chemical precipitation to remove ions of concern. XtremeUF filters out precipitated solids, producing clean water for downstream treatment. Output: Filtrate suitable for further processing or release; solids managed separately.

SaltMaker MVR crystallizers evaporate concentrated brine, recovering the final water fraction and converting residuals into solid salts for safe disposal or reuse. Output: Distilled water + dry solids; no liquid discharge.

Saltworks delivers modular, high-recovery water treatment systems engineered for cost-efficiency, reliability, and rapid deployment. Built and commissioned off-site, our fully automated solutions minimize operational disruption and excel in remote, demanding environments. Our advanced automation reduces operator intervention, while 24/7 remote monitoring, predictive analytics, and daily reporting optimize uptime, maintenance, and continuous performance.

Contact our engineers to explore how Saltworks’ modular solutions can help achieve your performance, compliance, and resource recovery goals.

XtremeUF ceramic and polymeric ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and FusionRO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

Saltworks introduces its second-generation Direct Lithium Extraction (DLE) technology, featuring a unique double-DLE process that delivers 90% eluate purity and cuts capital costs by over 25%. Built on a patented design using alumina adsorbents and pressurized membranes, the system has undergone extensive trials and optimization.

Saltworks provides Strategic Technical Services to support corporate industrial water and lithium processing strategies with expertise garnered through our in-house piloting, production and operation.

Saltworks brings water mining expertise and advanced desalination technologies to our lithium clients, offering solutions for concentrating, refining, and converting low-grade lithium sources to battery-grade product. We offer higher purity and lower energy processing technology, that boosts yield, removes unit operations, and reduces cost.

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).