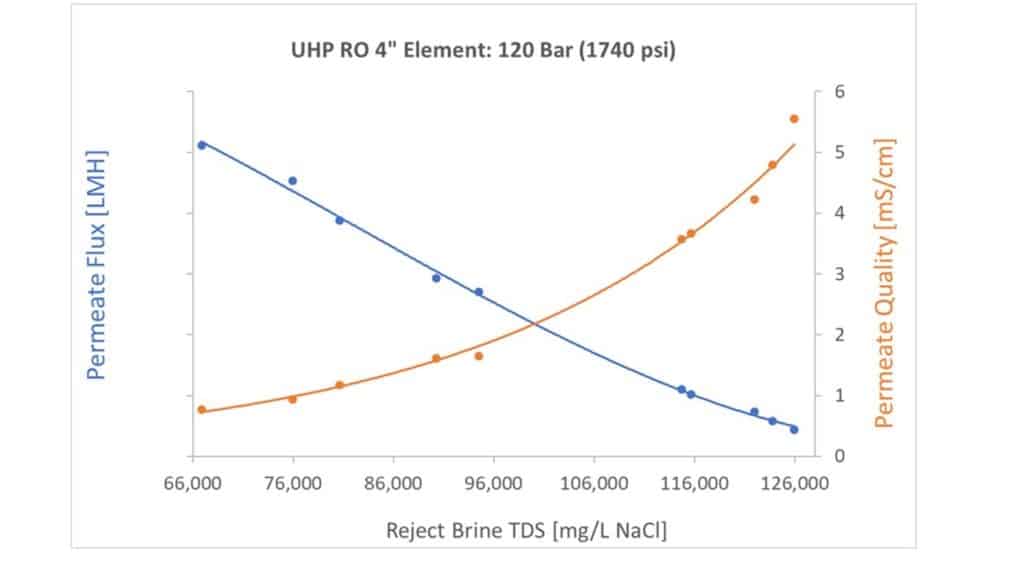

The increase in permeate salinity with brine concentration is expected. The RO membrane surface rejects a percentage of salt, for example 99.8%. This means roughly 0.2% of salt permeates through the membrane with the water. Naturally, at higher brine concentration more salt gets through the membrane. Also, operation at lower flux results in lower rejection. The slightly higher salinity permeate can be blended with other lower salinity permeates, using as flush source for upstream ROs, or further refined in a low-pressure polishing RO process. The primary objective and cost driver when applying UHP RO should be brine concentration and volume reduction.

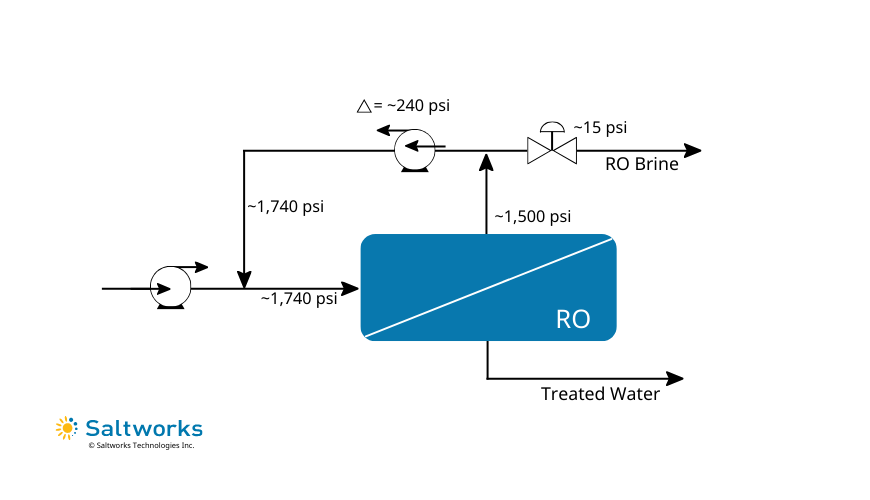

Figure 1 also shows the flux declining at higher salinity. Flux values in liters per m2 per hour (LMH) represent proprietary knowledge available only to Saltworks’ customers and partners. Nevertheless, the lower flux trend in Figure 1 is clear and translates into the need for either higher pressure, more membrane area, or both. With the advent of new 1,740 psi UHP RO membranes, designers can apply higher pressures to improve flux at higher TDS, and ultimately concentrate a sodium chloride solution to 130,000 mg/L TDS. If sulfates are present as an appreciable mass fraction, the brine concentration limit increases up to 160,000 mg/L TDS. At these high TDS ranges, flux decreased by three times relative to RO systems operating at 30-60K mg/L TDS. This means more membrane elements, pressure vessels, and pipework in addition to the higher pressure rated equipment.

Ultimately, capital cost of UHP RO systems is notably higher than the cost of brackish or seawater RO systems (SWRO). Although more expensive than SWRO, UHP RO still has a much lower cost than thermal evaporators. For this reason, UHP RO can be applied upstream of evaporators, to reduce capacity and energy of more expensive evaporation, or reduce volumes sent to disposal or evaporation ponds. It is important to keep in mind that evaporators can achieve higher brine concentrations and produce lower volumes than UHP RO. For larger flow rates, a combination of technologies, each operating at an optimum capacity, may be the most economical. Typical brine concentration limits and volume reduction ratios are summarized in Table 1.