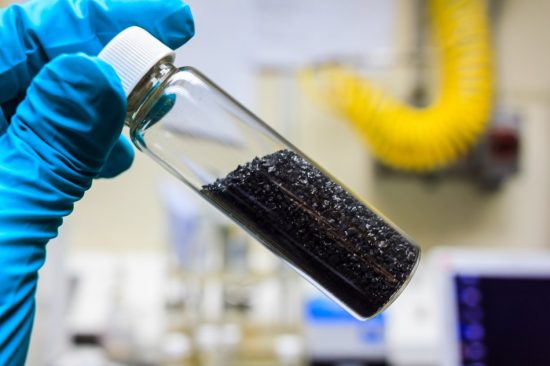

Zero Liquid Discharge (ZLD) and Minimal Liquid Discharge (MLD) Become Lower Cost Through Reverse Osmosis Innovation

Saltworks is pleased to announce that recent advancements in reverse osmosis technology are now commercially available. Reduce conventional RO brine volumes by 50%, achieving brine concentrations of 130,000 to 150,000 mg/L TDS with spiral wound RO membranes.