Hard Rock Spodumene Lithium Processing

Aqueous processing while recovering waste lithium and achieving ZLD

Dec 27th 2023

Article Highlights

- Over half of the world’s lithium is extracted from hard rock spodumene, a crystalline mineral also known as lithium aluminum inosilicate (LiAl (SiO3)2).

- While the majority of lithium-rich spodumene is currently mined in Australia and processed in China, there is significant potential to add extraction and processing capacity in North and South America.

- To produce battery chemical inputs, spodumene is mined, ground and acid-roasted. The resulting solution undergoes concentrating, refining, and converting (CRC) into lithium carbonate or lithium hydroxide.

- Two process pathways to achieve battery-grade chemical production from spodumene are summarized herein, with a focus on improving process yields and costs in the saline water circuit.

Overview

Lithium (Li) is essential to the electrification of transport and energy storage. It is widely used in modern battery technology due to energy density advantages. Although lithium is widely abundant in the earth’s crust, demand projections reveal a need to increase processing capacity by ten times in the next ten years.

Currently, hard rock extraction accounts for over 60% of global lithium production and supports the ever-growing demand for electric energy storage. The majority of such hard rock extraction and processing occurs in Australia and China respectively, but global interest and capacity for production is rapidly shifting.

This article explores hard rock to battery-grade lithium chemical pathways and provides insights for increasing lithium recovery and lowering costs through Saltworks’ concentrate, refine, convert (CRC) technologies.

Hard Rock (Spodumene) Lithium 101

While lithium can be found in various other igneous rocks, the relatively high concentrations of Li in spodumene (LiAl (SiO3)2) render this hard rock an important and commercially viable ore. Spodumene deposits can be found in various countries, including Brazil, Canada, and the USA.

At time of writing, most of the global spodumene supply is mined in Australia and shipped to China for processing, although this trend is beginning to shift.

Within Chinese lithium refineries, the spodumene ore undergoes intensive processing (Step 1) to produce lithium sulfate, which must then be further refined (Step 2) into battery-grade lithium carbonate (Li2CO3) or lithium hydroxide (LiOH).

Spodumene to Lithium Process Summary

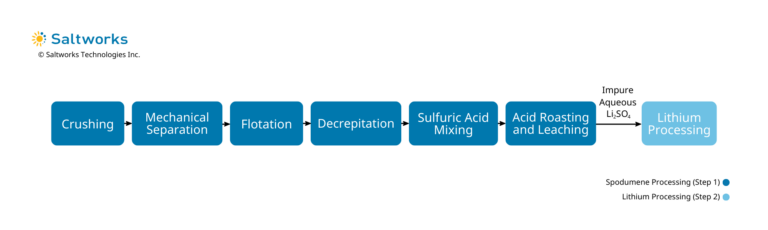

In step 1, to convert spodumene into lithium sulfate (Li2SO4), the raw ore is crushed and separated both mechanically and via floatation. Next, the concentrate undergoes energy- and chemically intensive hot acid-roasting. This process (as shown in Figure 1 below) sees concentrated spodumene powder roasted at 1050°C, cooled, mixed with sulfuric acid, and then re-roasted at 200°C to produce water-soluble Li2SO4.

Traditionally step 2 involves multi-stage water-based processes which vary depending on the refinery. Saltworks’ modular concentrating, refining, and converting (CRC) technologies provide a cost-efficient and rapid pathway to produce high-yield, battery-grade lithium carbonate or lithium hydroxide. Both process flows, including wastewater lithium recovery, are detailed below.

Saltworks Spodumene-Lithium Process Flow

Application of Saltworks’ concentrate, refine, and convert (CRC) technology begins with the input of dissolved lithium, in this case, an impure aqueous solution of Li2SO4 emerging from the previous sulfuric acid leaching process.

Lithium sulfate may be refined and converted into lithium hydroxide for use in NMC (nickel-manganese-cobalt) batteries, or lithium carbonate which is often employed in lithium iron phosphate (LFP) batteries.

NMC batteries claim higher range and energy density benefits, and are often found in high-performance vehicles. LFP batteries are known for their lower cost mass market appeal and higher cycle rates.

Commonly, although not exclusively, spodumene is converted to lithium hydroxide, which typically enters the NMC battery supply chain. On the other hand, lithium carbonate often enters the LFP battery supply chain.

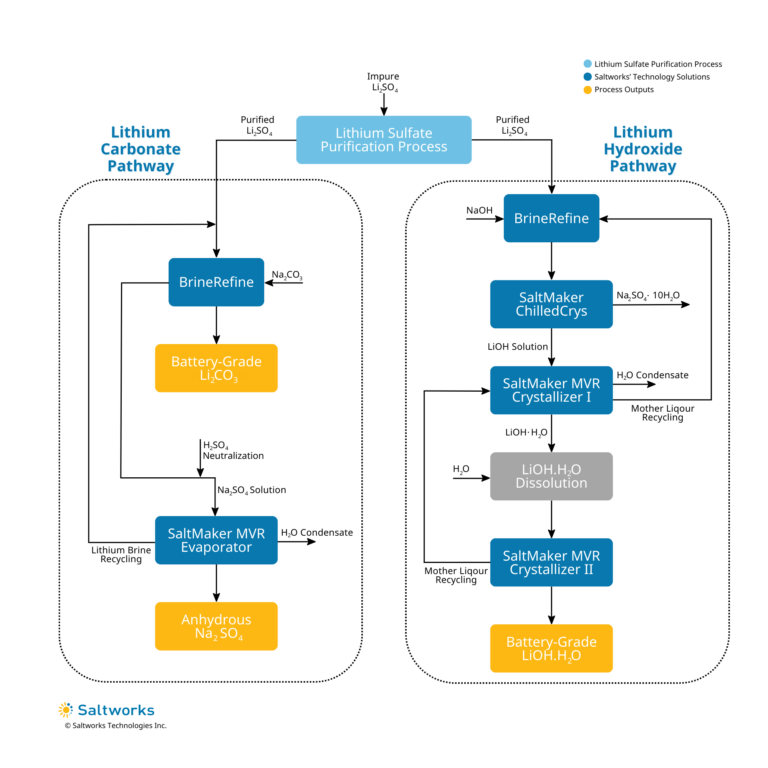

As shown below in Figure 2, processing spodumene into both lithium carbonate and hydroxide is possible with the same initial steps:

i. Coarse refining of the contaminated lithium sulfate through hardness and metal removal (BrineRefine),

ii. Concentration via evaporation (SaltMaker MVR Evaporator), and

iii. Fine purification via high-total dissolved solids ion exchange polish (XtremeIX).

This upfront process precisely targets impurities to ensure high lithium quality and yield downstream. From here, the purified Li2SO4 enters the lithium carbonate or lithium hydroxide pathway as described below.

1.Lithium Carbonate (Li2CO3) Pathway:

Purified Li2SO4 is combined with sodium carbonate (Na2CO3) in Saltworks’ BrineRefine (reconfigured) to produce battery-grade lithium carbonate. To produce battery-grade chemicals, the crystallization process must be preciously engineered and controlled, and coupled with solids separation and washing techniques. Saltworks delivers modular and automated packages to achieve battery-grade lithium carbonate with a single crystallization step, removing the need for costly and chemically intensive two-step crystallization.

2.Lithium Hydroxide (LiOH) Pathway:

Production of LiOH starts similarly with purified lithium sulfate combined with NaOH in BrineRefine. The resulting solution is then fed to SaltMaker ChilledCrys. Saltworks’ proprietary crystallizer offers exceptionally lower costs owing to using a fraction of the energy often required to process specific chemistries.

After the removal of Na2SO4, the resulting LiOH undergoes a two-step crystallization process with a SaltMaker MVR crystallizer to produce battery-grade lithium hydroxide. This technology’s forced-circulation systems are fully automated, with built-in self-cleaning to ensure reliability at optimal capacity. During both crystallization phases, mother liquor can be recycled to recover lost lithium.

Both process pathways produce high-salinity wastewater that can account for over 4% of the total lithium lost. Saltworks’ technologies offer opportunities to recover and recycle this lost lithium, while also achieving cost-efficient saline water treatment. Given the high cost of upfront processing, recovering lithium while treating the saline wastewater presents an interesting business case for all spodumene facilities.

Spodumene Wastewater Treatment & Lithium Recovery

Spodumene processing produces sodium-rich wastewater, containing close to 5% of the plant’s total lithium load.

In the lithium carbonate flowsheet, the wastewater blowdown from the carbonation reactor is nearly saturated in sodium sulfate with ~1,500 – 2,000 mg/L of lithium.

In the lithium hydroxide flow sheet, low-volume but highly concentrated boil-out liquors are released from the evaporative crystallizers to remove impurities and reduce boiling point elevation rise. Boil-out liquors also contain material amounts of lithium, worth considering for recovery.

In many jurisdictions, this ultra-high salinity wastewater cannot be discharged without treatment. This often requires zero liquid discharge crystallization of all salts for safe disposal. As the wastewater is concentrated and crystalized, dissolved lithium is also concentrated. It may be recovered as lithium carbonate or lithium phosphate with Saltworks’ solutions.

De-Risking Your Project with Saltworks

Saltworks’ concentrate, refine and convert technologies contribute to spodumene processing. They are designed with scalable modularity and smart digitization at their core, resulting in lower installation and start-up costs.

Our engineering can support total system modelling and mass balance optimizations to achieve high-yield, battery-grade lithium chemicals efficiently and cost-effectively.

With that, Saltworks’ Lithium Test Center, staffed with our experienced scientists and engineers, is ready to de-risk your lithium refining project. Our world-class manufacturing facility produces high-quality pre-commissioned modular process plants that accelerate your project toward production goals.

Contact our experts today to begin exploring your lithium CRC project options.

About Saltworks

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.