Industrial Wastewater Reuse Options

Maximizing water return on investment: analysing treatment options and using smart load management

Apr 10th 2024

Article Highlights

- Industrial water reuse offers security against water scarcity, rising wastewater disposal costs, and tightening environmental regulations.

- Effective water reuse should begin with reducing usage by preventing leaks, before considering more complex and costly treatment.

- Treating wastewater to a ‘fit-for-purpose’ reuse quality can save costs.

- Expert consultation and advanced systems and services can ensure reuse targets and the expected return on investment are achieved.

What is Industrial Wastewater Reuse?

Industrial wastewater reuse is the process of treating wastewater to be reused in the same initial production or extraction process that produced the stream, or in another independent process.

Wastewater reuse is increasingly important for operators, sectors and regions seeking to reduce costs, protect operations from growing water scarcity, and meet discharge limits and sustainability targets.

Water reuse offers the opportunity to turn a potential financial and environmental liability into a valuable asset. Innovation and cost reductions in treatment technologies make it ever more economical for businesses to reuse greater volumes and a wider variety of wastewater sources.

Some examples of industrial reuse include water for processing, reinjection, cooling systems, boilers, irrigation, cleaning, or groundwater recharge.

Wastewater Reuse Drivers

The main reasons for industrial wastewater reuse are addressing water scarcity, reducing costs, ensuring regulatory compliance, and demonstrating social responsibility.

Water scarcity: Drought conditions may result in businesses having limited freshwater withdrawal or cut-offs, impacting their ability to operate or expand. Climate change is also increasing drought severity. Wastewater reuse provides a constant and reliable freshwater source.

Reducing costs: Reuse can reduce costs in two ways. Firstly, many industrial processes do not need high-quality freshwater, so wastewater can be cleaned to a ‘fit-for-purpose’ level which may be less costly than freshwater. Secondly, Industrial wastewater reuse also reduces the need and risks associated with offsite disposal which can be very expensive due to transportation costs. Industrial wastewaters may require specialized, more costly disposal. There is also the risk of offsite treatment or disposal facilities increasing fees or imposing stricter wastewater acceptance criteria.

Regulatory compliance: As national, state and local governments tighten water quality regulations, water reuse is a useful strategy for achieving compliance. Many jurisdictions are increasingly requiring greenfield projects to meet wastewater reuse targets.

Social responsibility: Wastewater reuse helps businesses meet ESG targets and align their activities with corporate sustainability goals. Reuse also reduces the impact on water supplies in local communities.

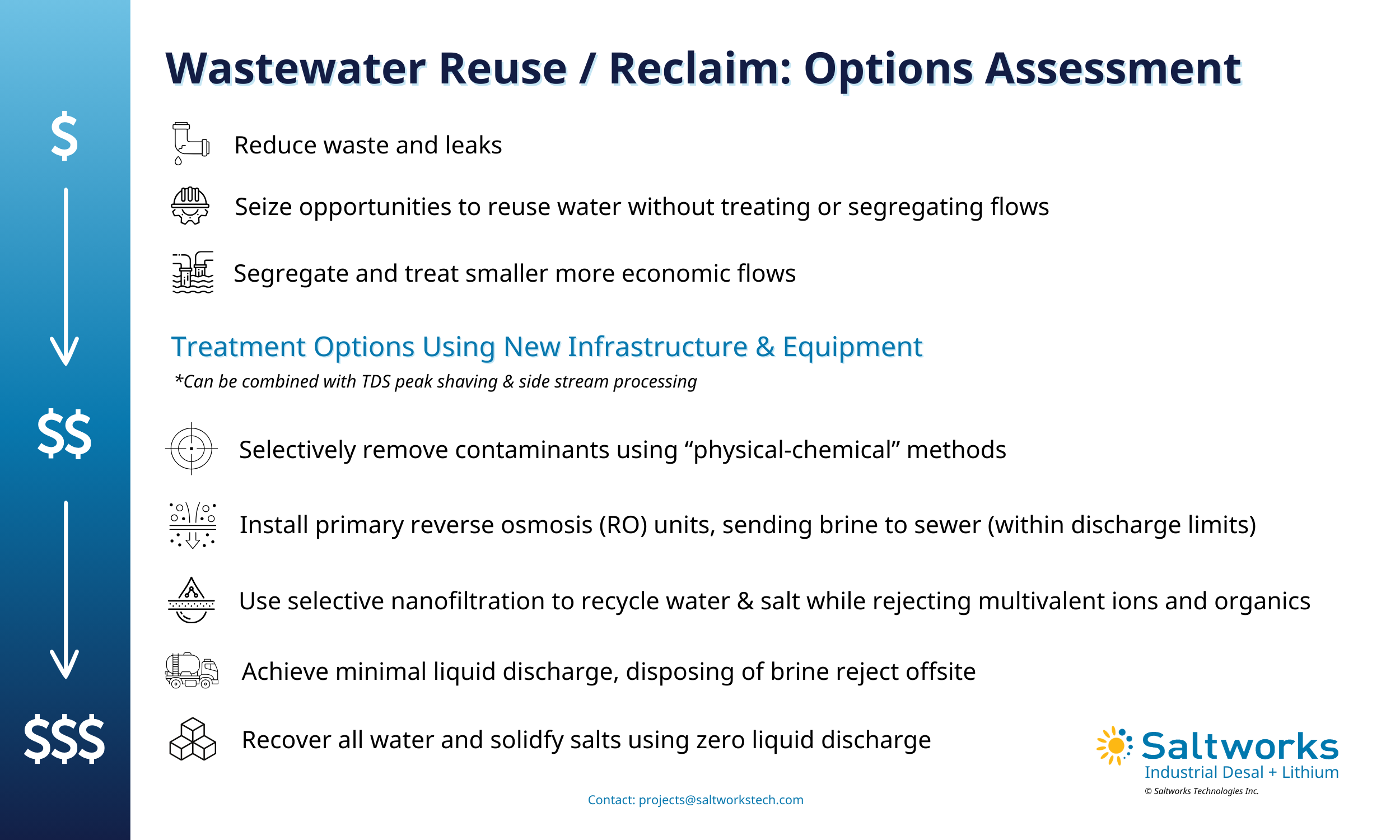

Start Simple

A general approach to industrial wastewater reuse is to start with easy-to-implement, low-cost solutions before considering more complex and costly treatment methods.

- Reduce usage: Measure and understand how water is used in the business or plant, identify and curtail usage on non-essential activities, and stop leaks by installing monitoring devices and repairing or replacing faulty or aging equipment and infrastructure.

- Identify wastewater sources and potential reuse targets: Sources may include process effluent, cooling tower blowdown, once-through cooling water, boiler blowdown, and ion exchange rinse waters. Reuse targets may include process water, cooling water, boiler feed, equipment cleaning, dust suppression, groundwater replenishment, irrigation, and general cleaning.

Depending on the reuse quality required, a wastewater source may be an inexpensive process feedstock. With careful planning, reuse objectives may be achievable with some re-plumbing and minimal additional treatment. Consider:

- closed loops by recycling water within a process.

- separating less contaminated sources from heavily impacted ones.

- segregating wastewater streams and treating these smaller flows separately rather than treating a larger volume flow with more contaminants.

Once wastewater sources are mapped to reuse targets, treatment objectives and methods can be identified.

Industrial Water Reuse Approaches

1. Selective Contaminant Removal (SCR)

The most cost-effective reuse treatment approach is selective contaminant removal (SCR). This involves targeted removal of specific compounds or ions instead of treating for all contaminants.

Compared to broader treatment, SCR uses less energy and chemical inputs and generates less residual waste.

SCR may include both chemical (e.g. reaction) and physical (e.g. filtration) processes. Examples include:

- Removal of scaling ions including hardness, metals and silica,

- Targeted treatment of hydrofluoric acid waste, heavy metals, sulfates and,

- Selective nanofiltration to produce a permeate for re-use while rejecting divalent ions.

SCR can also recover valuable by-products from waste streams, such as cobalt or nutrients such as phosphorous. Read more about Saltworks’ selective contaminant removal systems.

2. Minimal Liquid Discharge (MLD)

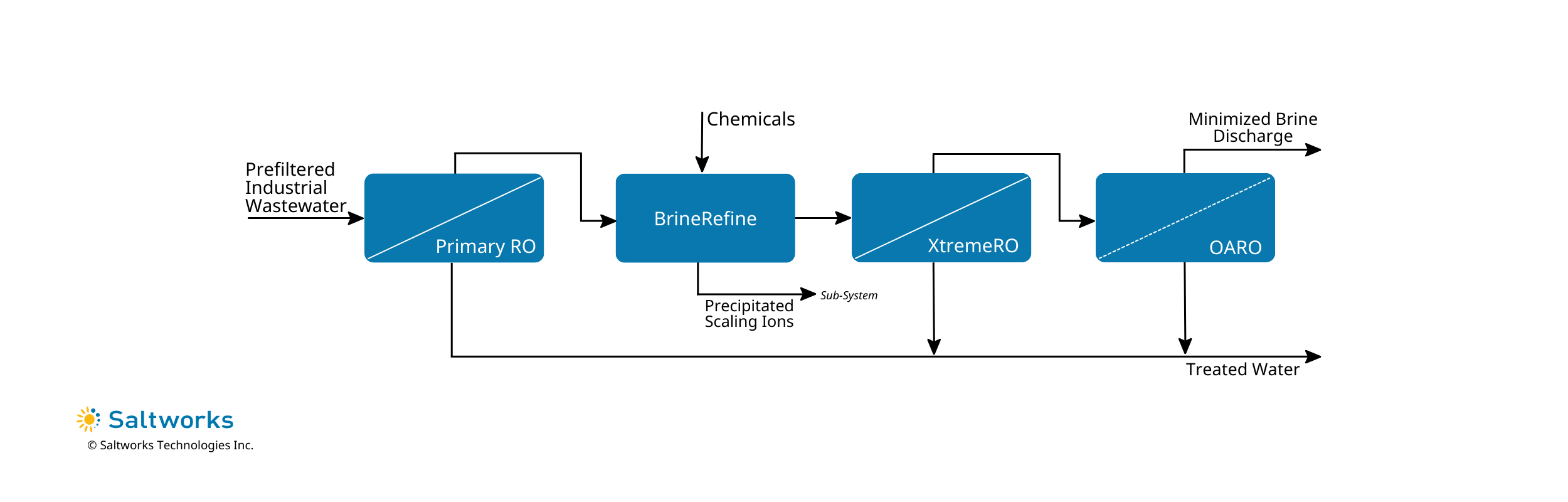

Minimal liquid discharge (MLD) is a more fulsome treatment that recovers freshwater while generating saline brine. MLD typically uses reverse osmosis (RO), the most widespread desalination technology.

MLD solutions range from relatively simple single-stage RO units to more complex systems aimed at maximizing freshwater recovery.

These may include multiple stages and newer RO variants such as ultra-high pressure RO or osmotically assisted RO. MLD systems may also include integrated chemical or other treatment processes to manage scaling ions to allow RO to achieve peak performance and reliability.

For example, a MLD system could include an initial 600 psi RO recovering freshwater and generating a brine saturated in scaling ions; followed by selective removal of scaling ions and 1200 psi RO to recover additional water; and finally 1800 psi ultra-high pressure RO or osmotically assisted RO to achieve the highest possible water recovery and brine concentration.

MLD has increased costs and complexity. Equipment performance and reliability, capital and operating cost, and residual brine management must be considered. Look for a provider with experience implementing MLD systems and expertise in treating the unique challenges of industrial water reuse. Read more about Saltworks’ MLD systems.

3. Zero Liquid Discharge (ZLD)

Zero liquid discharge is the next option when MLD treatment does not meet discharge targets or if brine rejects cannot be cost-effectively disposed of or stored.

ZLD employs evaporation and crystallization processes to recover additional freshwater as a distillate while generating residual solids. These must be managed, typically by offsite landfill disposal.

End-to-end ZLD systems often start with a membrane-based MLD system, followed by a thermal evaporator-crystallizer, and a final solids management process such as a decantifying centrifuge. ZLD is the most complex and costly method for achieving reuse and should only be considered when other options are exhausted.

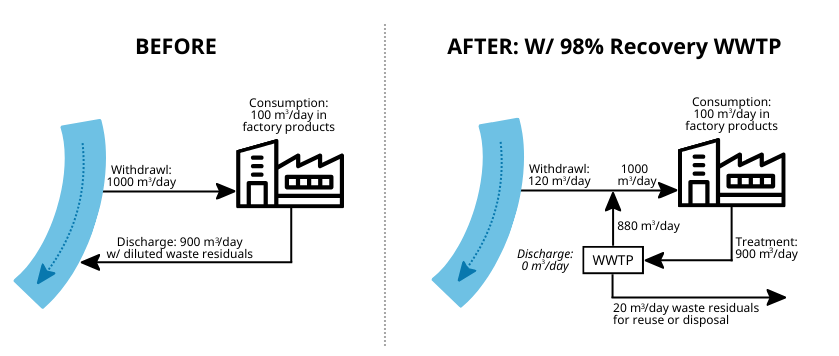

Example to Reduce Withdrawal and Discharge Risk

As an example, the factory shown in Figure 3 below requires 1000 m3/day, of which 100 m3/day is consumed during production. 900 m3/day containing waste residuals is discharged back into the environment.

In this case, if the factory withdrawal or discharge limits change because of permitting, water stress, public pressure, etc., then a MLD wastewater treatment plant (WWTP) as depicted below can offer 98% water recovery while producing minimal liquid discharge for disposal. This would result in no discharge back to the environment.

Water reuse requires MLD and ZLD once recovery requirements reach a certain level. As the cost and complexity of treatment and residuals management increases, MLD and ZLD systems require careful planning and design to ensure expected return on investment.

Saltworks helps clients understand their options and develop a strategy with a staged rollout to achieve reuse objectives. Read more about our ZLD systems.

4. Peak Shaving and Side Stream Treatment

Additional approaches for meeting reuse targets include peak shaving and side stream treatment.

If an industrial process generates wastewater non-continuously or with fluctuating volumes, then peak shaving can be used to treat only the excess volume generated during these peak periods.

This can be accomplished by storing the excess volume and treating it during non-peak periods instead of paying for costly offsite disposal. Peak shaving works best when loads vary predictably, for example when wastewater volumes are highest during the day and drop off at night.

Alternatively, side stream treatment is useful for meeting reuse quality without treating the full wastewater flow. Treatment is applied to only a portion of the wastewater flow, and the smaller volume treated stream is blended back in to achieve the desired quality.

Side stream treatment is most effective when a particular point in a process has a high contaminant concentration. A smaller capacity system can treat a lower volume flow at this point and achieve the desired end result at a lower cost.

Peak shaving and side stream treatment can be cost-effective ways to meet reuse objectives with a relatively lower additional investment in equipment or infrastructure.

Both approaches require careful analysis of flows, an understanding of water chemistry, and reliable monitoring. Working with an expert with experience in using these methods for industrial wastewater reuse is recommended.

Achieve Reuse Targets with Saltworks

Industrial operators seeking to implement initial reuse or expand existing reuse capabilities should always start with a thorough assessment of their various wastewater streams and reuse opportunities.

Saltworks’ experts tackle reuse projects through thorough analysis of flow rates, chemistry, and economics. We design and engineer complete reuse process, conduct comprehensive pilot testing, and deliver a full-scale reuse system with after-sales support.

Contact us today to begin your wastewater reclamation project.

About Saltworks

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.