SaltMaker AirBreather Evaporator Crystallizer

Open-to-atmosphere evaporator, operating at low temperatures to concentrate brine.

Oct 15th 2018

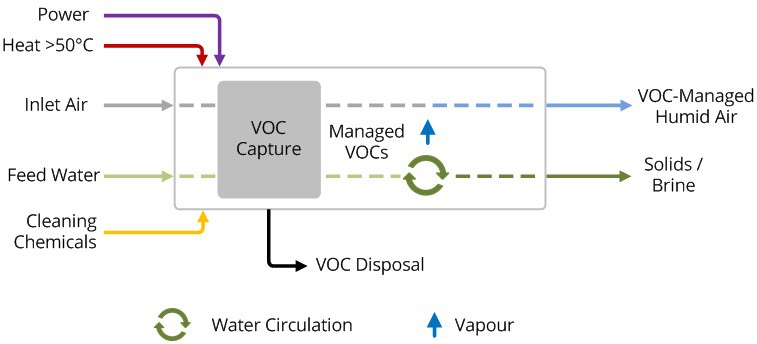

Wastewaters can contain substances with low boiling points that will evaporate with water. Examples include ammonia, or volatile organic compounds (VOCs) such as methanol, BTEX, and others. Odor may also impact neighbours. The AirBreather’s proprietary “Volatile Management System” prevents volatiles from atmosphere contact so that only safe, clean, low-temperature water vapor is released. Our pilot plants are outfitted with this same system, so we can prove the operations at your site, or ours on shipped water.

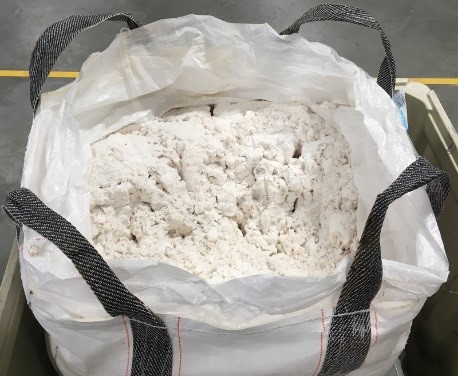

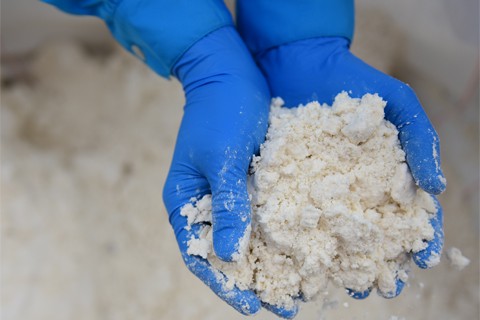

Samples of solids as produced and discharged to an automated bagging system

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Open-to-atmosphere evaporator, operating at low temperatures to concentrate brine.

There are four fundamental types of industrial evaporators and crystallizers used for wastewater treatment, brine management, or improving water reuse. Lower your risks and improve costs by understanding the trade-offs between the different evaporator types.

Scale is a crust that forms on membranes, heat transfer surfaces, and on the inside of pipes as salts precipitate out of solution. It blocks flow, disrupts heat transfer, and increases energy requirements for water treatment systems

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).