Solar Cell Manufacturing—Industrial Wastewater Treatment Challenges and Solutions

Treatment options and solutions for heavy metals, fluoride, organics and more.

January 3rd 2024

Article Highlights

- Solar photovoltaics (PVs) will soon be the fastest growing method of power generation. PV technologies are broadly categorized as crystalline silicon or thin films.

- Solar PVs manufacturing facilities produce industrial wastewater streams with complex chemistries, which must be managed for reuse, discharge, or disposal. Constituents of concern include fluoride, organics, metals, suspended solids, acids, alkalis, and others.

- Fluoride is one of the most important wastewater constituents to be considered. Many regions impose strict fluoride discharge limits—as low as 2 mg/mL.

- Saltworks’ industrial wastewater expertise and suite of technologies help its clients to meet their wastewater goals, from targeted chemical solutions to cost-optimized zero liquid discharge.

Types of Solar Photovoltaics

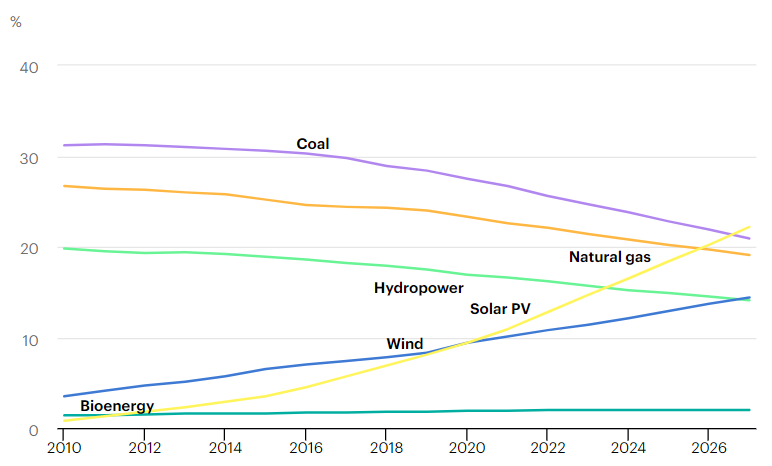

The installed power capacity of Solar PVs has grown faster than any other source over the past decade (figure 1). Technological advancements and manufacturing capacity increases have resulted in dramatic cost reductions.

Commercialized solar PV technologies are broadly grouped into two categories: crystalline silicon and thin films (see Table 1). Other technologies are also being developed such as organic and perovskite solar cells. Crystalline silicon includes poly- and mono-crystalline types and dominates the market. Thin film technologies include cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and amorphous silicon (a-Si), which are accelerating in development and manufacturing scale.

Table 1: Summary of Commercial Solar PV Technologies

| Crystalline Silicon | Thin Films | |||

|---|---|---|---|---|

| Mono/Poly-Crystalline | Cadmium Telluride | Copper Indium Gallium Selenide | Amorphous Silicon | |

| Efficiency | High (15–18%) | Moderate (6–9%) | Moderate (7.5–9.5%) | Low to Moderate (4–8%) |

| Cost | Medium-High | Low | Medium | Low-Medium |

| Advantages | Most widely used, high market share, most power per footprint | Low-cost production, good in low light | Flexible, potential for future higher efficiency | Flexible, works well in diffuse light |

| Disadvantages | Relatively high manufacturing costs, in part due to high temperatures needed | Cadmium is toxic (though CdTe is not and is very stable). Tellurium is relatively rare | Not highly commercialized. Indium is rare and expensive | Low efficiency limits power per area |

Common Solar PV Water Challenges

Manufacturing of all commercially available solar PV requires significant water volumes and produces wastewaters that require careful management. Water uses include processes such as etching, cleaning, and cooling. One common water challenge is ensuring sufficient freshwater supply due to withdrawal limits. Other challenges include meeting discharge limits for specific chemicals and characteristics such as total dissolved solids (TDS) and chemical oxygen demand (COD).

Read more

Various solutions, depends on chemistry

Read More

Contact us

Contact us

Read More

Figure 2: Some of the main constituents and characteristics of concern in solar PV wastewaters.

Ultrapure Water: Ion Exchange and RO Wastewaters

Deionized (DI) or ultrapure water (UPW) is required for some PV production processes. These high purity waters are usually produced using reverse osmosis (RO) and ion exchange. Producing high purity waters can create substantial wastewater volumes in the form of RO reject and ion exchange regeneration brines. Saltworks delivers solutions that optimize reuse and disposal, by lowering total dissolved solids (TDS) or concentrations of specific constituents, with options for minimal or zero liquid discharge.

Metals

Production of solar PV electrical contacts, wiring, and interconnections involves metals such as aluminum, copper, silver, lead, molybdenum, tin, and nickel, with the first three being the most important. Removing metal impurities during processing may require cleaning in acids, such as nitric or hydrochloric. Wastewaters from rinsing after metallization or soldering contacts are also often acidic and contain metals.

Smart wastewater treatment systems should be in place to remove or reduce metal concentrations where necessary. Saltworks delivers solutions that achieve this, and in some cases, recover valuable materials. Treatment solutions for metals may include pH adjustment, precipitation, flocculation, clarification, and/or ultrafiltration.

Organics and Other Advanced Manufacturing Challenges

Common industrial solvents, such as trichloroethane, toluene, isopropanol, xylene, and acetone, are also frequently used in solar PV production processes for cleaning. Options for treating these organic solvents in wastewater include activated carbon adsorption, biological treatment, distillation, membrane separation, and chemical oxidation (including Fenton’s reaction). Organic treatment systems need to be chosen and engineered carefully, with consideration of operating conditions, full wastewater flow chemistry, and economics. During solar PV lithography, polymers are also used as photoresists for deposition processes. Resist material in wastewater streams is usually precipitated, filtered, and disposed of as solid waste.

Other constituents used in solar PV manufacturing processes include ammonia, silicon tetrachloride, surfactants, corrosion inhibitors (e.g. azoles), flame retardants, anti-scalants, and coagulants—all of which may require wastewater chemistry expertise to address cost-effectively.

Working with a Saltworks expert helps to determine the best solutions for polymers, other organics, and other industrial wastewater challenges.

Crystalline Silicon PV: Specific Wastewater Challenges

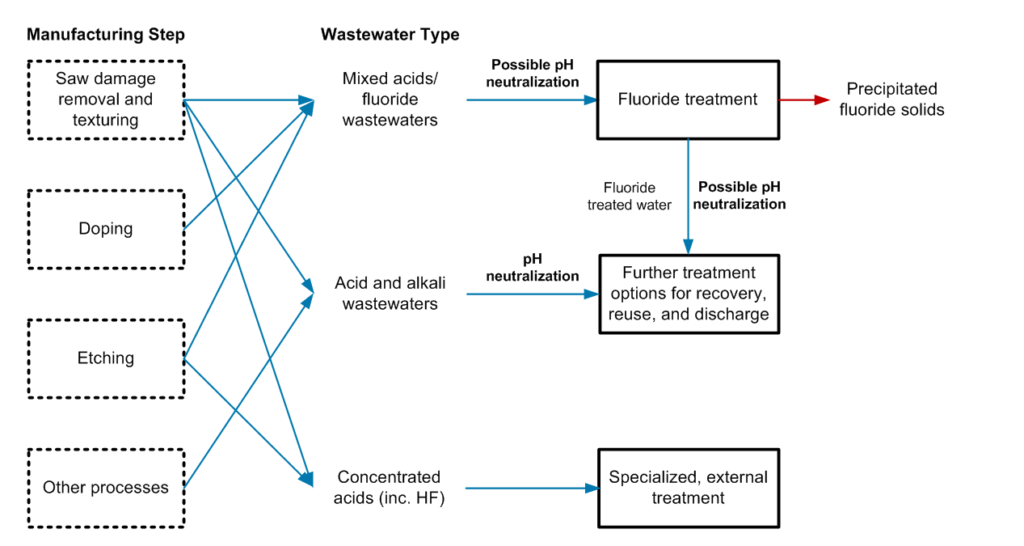

The most important considerations in crystalline silicone PV manufacturing wastewater include acids, alkalis, suspended solids, and hydrofluoric acid/fluoride, as shown in figure 3, as well as the general concerns mentioned above.

Sawing: Cooling Fluid and Suspended Solids

To achieve the desired precise silicon wafer thickness—in the hundreds or even tens of microns—specialized wire saws are used. To prevent overheating of the saws, large volumes of water or mixtures of polyethylene glycol (PEG) are used. Treatment of PEG in wastewater may require relatively specialized processes, such as biological destruction.

During wafer sawing, silicon material may be lost as small particles. In addition, silicon carbide powder may be used as an abrasive in the cutting process. Silicon and silicon carbide particles exist as suspended solids in wastewater flows, which may require treatment using technologies such as clarifiers or ultrafiltration. It is especially important to remove suspended solids before treatment using reverse osmosis (RO), as these particles will damage RO membranes. Options for the removal of silicon particles using membrane technologies such as XtremeUF are available.

Alkaline Texturing

Solutions of sodium hydroxide (NaOH) or potassium hydroxide (KOH) are used in the processing of silicon wafers, including as part of alkaline texturing. This process enhances light absorption and the resulting efficiency of solar cells by reducing surface roughness. It may be used in particular to mitigate wafer sawing damage. Alkaline wastewater containing silicon can cause the evolution of hydrogen, thus treatment processes must be carefully designed to avoid explosion risks.

Dopants and Etching with Hydrofluoric Acid

Silicon dioxide typically forms as a native layer on the surface of silicon wafers. Phosphorous is the most common n-type dopant in silicon, which may result in a layer of silicon phosphide forming on the wafer surface. These undesired layers are typically etched using solutions of hydrofluoric acid, often mixed with nitric acid), leaving a clean silicon surface.

Hydrofluoric acid etching generates wastewaters with elevated fluoride concentrations, often with suspended particles (TSS). Our fluoride blog summarizes how our BrineRefine and XtremeUF systems have modernized the treatment of fluoride and TSS. They produce low-volume, non-hazardous, and insoluble solids for easy landfill disposal.

Thin Film PV: Specific Wastewater Challenges

In addition to general wastewater concerns, depending on the solar PV type, thin film manufacturing wastewaters require consideration of cadmium, tellurium, copper, indium, gallium, selenium, as well as other metals and compounds. CdTe solar PVs are the most established of the thin film technologies.

CdTe PVs: Cadmium, Tellurium and Cadmium Telluride

There is little concern over the safety of the finished product of cadmium telluride (CdTe) solar panels, because of the chemical stability of CdTe and how it is packaged in solar PV devices. However, constituents of concern are used in their manufacturing. Deposition of CdTe layers is performed using a bath or vapor deposition process, resulting in one or more liquid waste streams containing cadmium. Cadmium is widely recognized as toxic. The US EPA regulations for drinking water limit cadmium to 0.005 mg/L. Cadmium may be removed using an ion exchange resin followed by pH adjustment. Although less studied, tellurium is increasingly coming under scrutiny. Saltworks provides solutions for heavy metals treatment in wastewater.

Contact Advanced Manufacturing Wastewater Experts

Solar PV manufacturers looking to optimize water use or waste management should always start with a thorough quality and quantity assessment of all wastewater streams, exploring opportunities to reduce disposal volumes or reuse water. Our industrial wastewater experts can analyze, design, and deliver cost-optimized solutions for solar industry clients. Send us a message today to begin.

About Saltworks

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.