Petrochemical Industry Wastewater Treatment

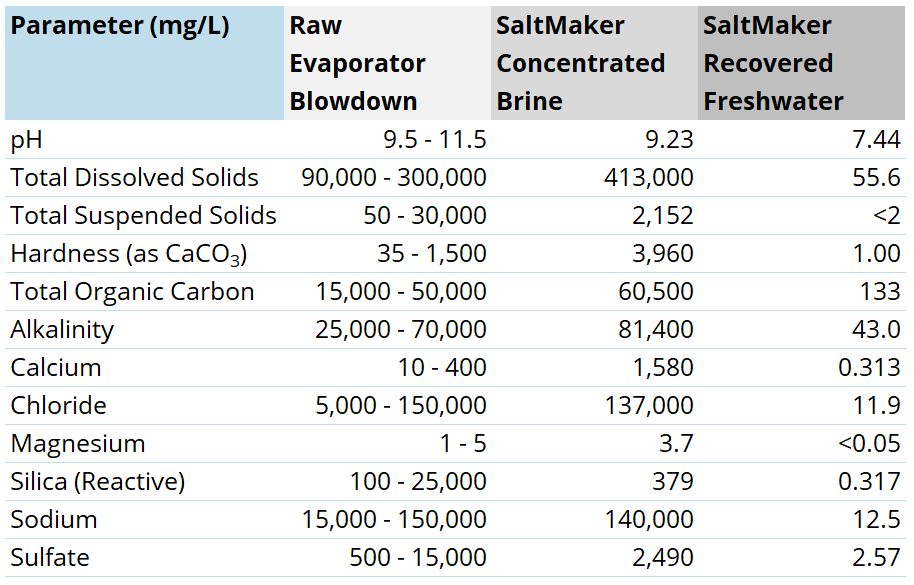

Saltworks can help meet the unique challenges of petrochemical industry wastewater treatment: boosting water recovery, saving energy, and lowering costs. Applications include process waters such as cooling tower blowdown, or wastewater that has contacted hydrocarbons and may include oils and grease, heavy metals, ammonia, and more.