Saltworks Launches Larger Modular SaltMaker MVR-30 Crystallizer and Secures New U.S. Patents

Saltworks launches SaltMaker MVR-30, doubling evaporation capacity to 30 TPH with patented intelligent automation for reliable ZLD and low maintenance.

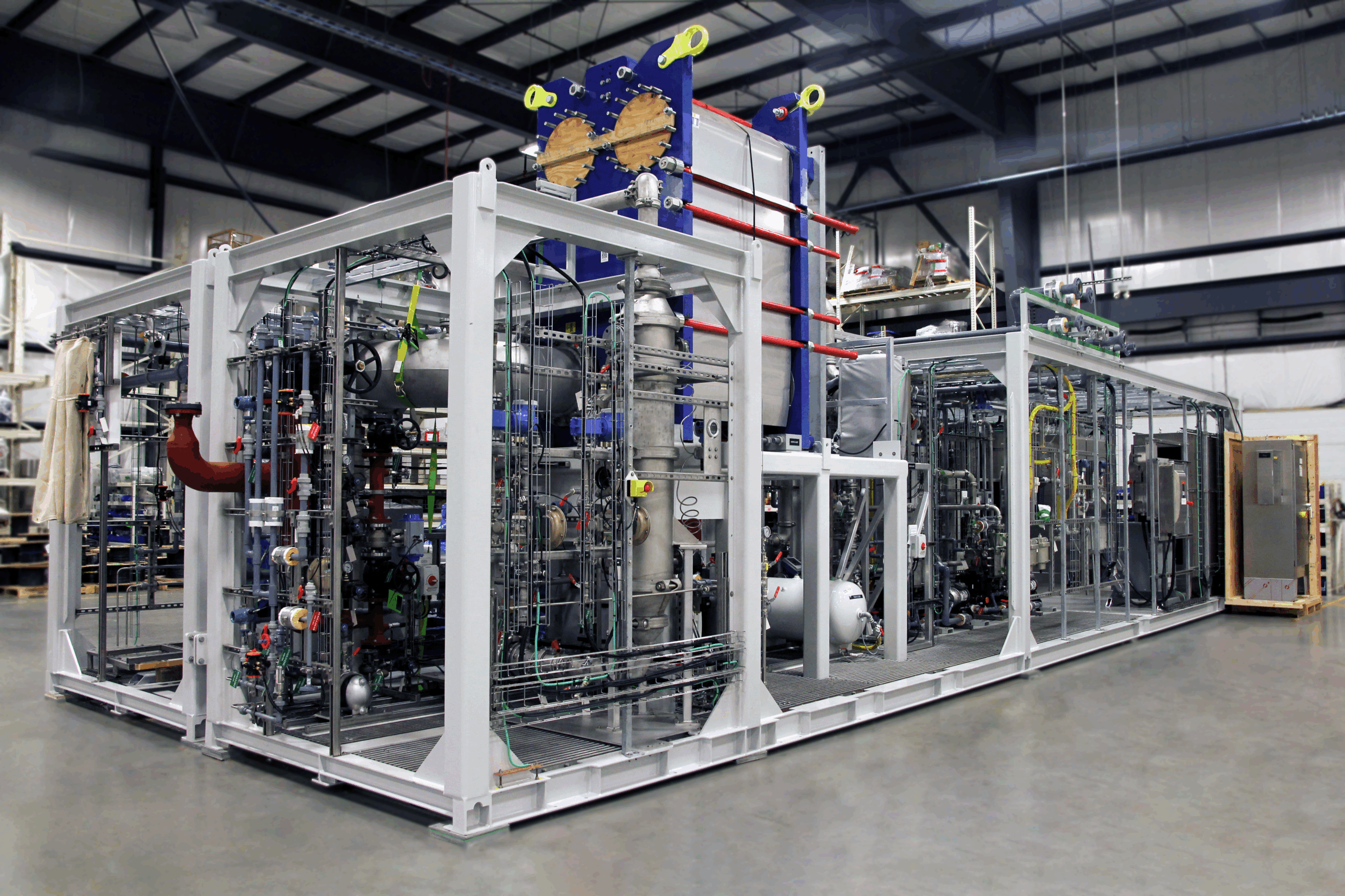

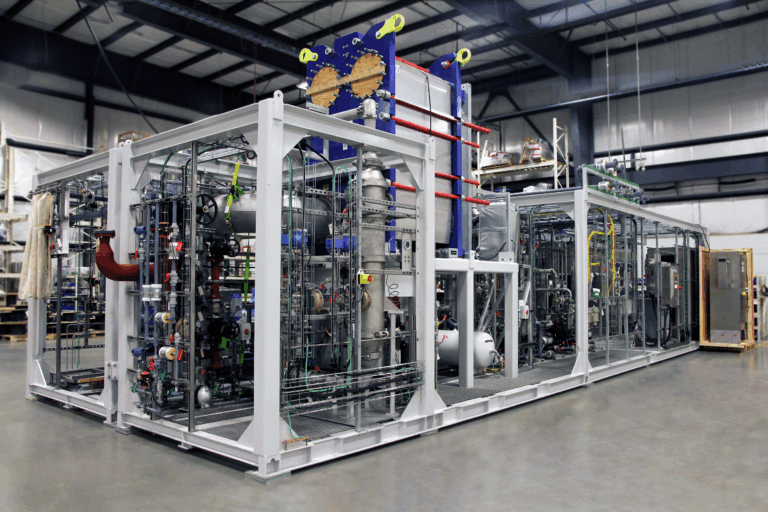

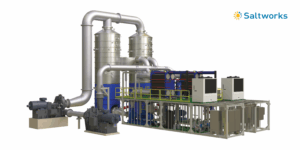

Saltworks’ SaltMaker MVR and MSF represent the evolution of forced circulation evaporator-crystallizer technology. Components and engineering are proven through repeat installations and designed for corrosive, scaling environments.

Plants are delivered as factory-built, pre-tested modular blocks in ISO-container sizes—easy to ship, set on footings, interconnect, and start up quickly at your site.

Patented intelligent automation delivers superior reliability and simplified operation, featuring self-diagnosis and self-correction controls.

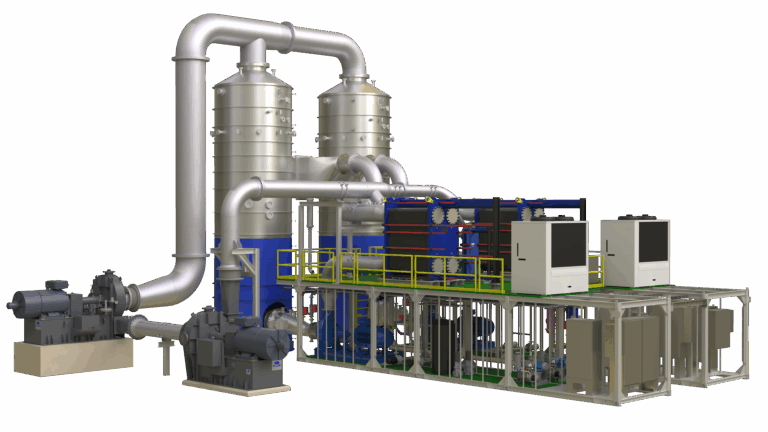

Like all mechanical vapour recompression plants, SaltMaker MVR uses a compressor to evaporate vapour from brine and condense distilled water, recycling the heat of condensation.

The vapour compressor provides a temperature rise across the heat exchanger. SaltMaker MVR only requires power to operate (no need for a gas line connection or heat) and is compact.

In addition to treating wastewater, SaltMaker MVR is also an industry-leading lithium brine concentrator and lithium hydroxide crystallizer.

Multi-stage flash evaporators and crystallizers use thermal energy to evaporate vapour from brine, lowering electrical energy consumption and removing the need for a vapour compressor.

Across multiple effects (stages) the heat of condensation is recycled to evaporate brine. Practically, a maximum of four forced circulation effects is common, while waste heat sources at 80°C may mean employing fewer effects.

Evaporation, crystallization, slurry management, and corrosion control require deep expertise.

Saltworks’ experienced chemists and engineers ensure your plant is designed and built for your specific application. Every SaltMaker is delivered as a fully automated system—from inlet to discharged water and solids—and includes an integrated decanter centrifuge with advanced slurry management.

Saltworks launches SaltMaker MVR-30, doubling evaporation capacity to 30 TPH with patented intelligent automation for reliable ZLD and low maintenance.

Saltworks has shipped two SaltMaker MVR crystallizers and a SaltMaker ChilledCrys to the electric vehicle (EV) battery industry. These full-scale systems will play an essential role in the production of lithium and nickel—two critical elements in EV batteries.

Zero liquid discharge (ZLD) is an engineering approach to water treatment where all water is recovered and contaminants are reduced to solid waste.

Our XtremeRO and FusionRO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.