ZLD Without Evaporation: Saltworks Achieves First ZLD With a Membrane Crystallizer

Saltworks’ engineers achieve ZLD without conventional energy-intensive boiling through a novel membrane-chiller and UHP-RO hybrid plant for a mining client.

Nov 16th 2017

Zero liquid discharge (ZLD) is an engineering approach to water treatment where all water is recovered and contaminants are reduced to solid waste.

While many water treatment processes attempt to maximize the recovery of freshwater and minimize waste, ZLD is the most demanding target because the cost and challenges of recovery increase as the wastewater gets more concentrated. Salinity, scaling compounds, and organics all increase in concentration, which add costs associated with managing these increases. ZLD is achieved by stringing together water treatment technology that can treat wastewater as the contaminants are concentrated.

Targeting ZLD for an industrial process or facility provides a number of benefits:

Several methods of waste management are classified as ZLD, despite using different boundaries to define the point where discharge occurs. Usually, a facility or site property line that houses the industrial process is considered the border or ‘boundary condition’ where wastewater must be treated, recycled, and converted to solids for disposal to achieve zero liquid discharge.

Certain facilities send their liquid waste off-site for treatment, deep well disposal, or incineration and they consider this to qualify as ZLD. This approach eliminates the continuous discharge of liquids to surface waters or sewers, but can significantly increase cost.

Some engineers describe their designs as near-ZLD or minimal liquid discharge to highlight that they discharge low levels of wastewater, but these processes do not eliminate liquid in their waste. For some facilities, it may be more economical to approach but not achieve complete ZLD by concentrating brine to lower volumes. Furthermore, it may be possible to avoid the creation of liquid waste on-site through careful water conservation or by treating contaminants at their source before they can enter the main flow of water.

Download our ZLD infographic for detailed information on costs.

In a world where freshwater is an increasingly valuable resource, industrial processes threaten its availability on two fronts, unless the water is treated. Many industrial processes require water, and then reduce the availability of water for the environment or other processes, or alternately contaminate and release water that damages the local environment.

Although the history of tighter regulations on wastewater discharge can be traced back to the US Government’s Clean Water Act of 1972, India and China have been leading the drive for ZLD regulations in the last decade. Due to the heavy contamination of numerous important rivers by industrial wastewater, both countries have created regulations that require ZLD. They identified that the best means to ensure safe water supplies for the future is to protect rivers and lakes from pollution.

In Europe and North America, the drive towards ZLD has been pushed by high costs of wastewater disposal at inland facilities. These costs are driven both by regulations that limit disposal options and factors that influence the costs of disposal technologies. Tong and Elimelech suggested that, “as the severe consequences of water pollution are increasingly recognized and attract more public attention, stricter environmental regulations on wastewater discharge are expected, which will push more high-polluting industries toward ZLD.”

Another important reason to consider ZLD is the potential for recovering resources that are present in wastewater. Some organizations target ZLD for their waste because they can sell the solids that are produced or reuse them as a part of their industrial process. For example, lithium has been found in oil field brines in the USA at almost the same level as in South American salars. In another example, gypsum can be recovered from mine water and flue gas desalinization (FGD) wastewater, which can then be sold to use in drywall manufacturing.

Regardless of an organization’s motivations to target ZLD, achieving it demonstrates good economics, corporate responsibility and environmental stewardship. By operating an in-house ZLD plant, disposal costs can be reduced, more water is re-used, and fewer greenhouse gases are produced by off-site trucking, which minimizes impact on local ecosystems and the climate.

To learn more about implementing ZLD solutions, contact us.

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Saltworks’ engineers achieve ZLD without conventional energy-intensive boiling through a novel membrane-chiller and UHP-RO hybrid plant for a mining client.

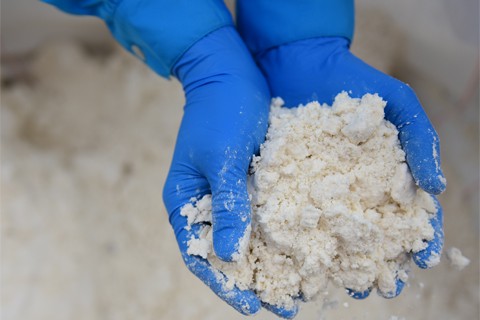

Our SaltMaker modular evaporators and crystallizers turn almost any wastewater into clean water, minimal liquid discharge (MLD) brines or zero liquid discharge (ZLD) solids.

Heavy industry, manufacturing, and natural resource-based industries often use large volumes of water and generate wastewaters requiring treatment. Saltworks designs, builds, and operates advanced wastewater treatment plants that economically and reliably treat tough industrial wastewaters.

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).