SaltMaker Evaporators & Crystallizers

Our SaltMaker modular evaporators and crystallizers turn almost any wastewater into clean water, minimal liquid discharge (MLD) brines or zero liquid discharge (ZLD) solids.

Saltworks » Applications » Ammonia Wastewater Treatment

Ammonia (NH3) is critical to many industrial and agricultural processes. As a serious and common water pollutant, it is heavily scrutinized and regulated. High ammonia concentrations can prevent the discharge or reuse of many wastewaters.

Biological treatment is widely used to remove ammonia, producing harmless nitrogen gas. However, biological treatment systems can be overburdened by increasing industrial wastewater volumes, or ammonia or organics loads.

Saltworks helps clients to meet ammonia challenges by providing new treatment systems or expanding existing ones. We ease the burden on downstream processes such as biological ammonia treatment or your discharge point.

Depending on your project, you could benefit from an ammonia stripper. Stripping ammonia produces a concentrated ammonium sulfate solution (~35%). This involves a high-pH stripping tower that removes ammonia, which is then absorbed in a low-pH scrubbing tower. The solution may be:

Saltworks optimizes ammonia treatment, boosting capacity. We start with a comprehensive mass and energy balance review, mapping the economics of alternatives. Once complete, we present options for optimizing the use of an ammonia stripper or for other options.

Stripping does not fit every project. Sometimes other options or combinations make sense, including:

RO treatment of ammonia requires specialized knowledge and plant configuration. Saltworks installs RO systems engineered to reject ammonia, operating at over 98% recovery. The result is clean freshwater that can be discharged, while wastewater is concentrated up to 50 times.

RO has moderate capital costs and very low operating costs assuming brine management costs are low. However, RO works best with non-scaling waters with TDS < 80,000 mg/L and when low-cost options for downstream ammonia brine management are available.

We can help you to consider your options—and if warranted, deliver an ammonia RO concentrator plant. We can also help with that final 2% concentrated ammonium waste.

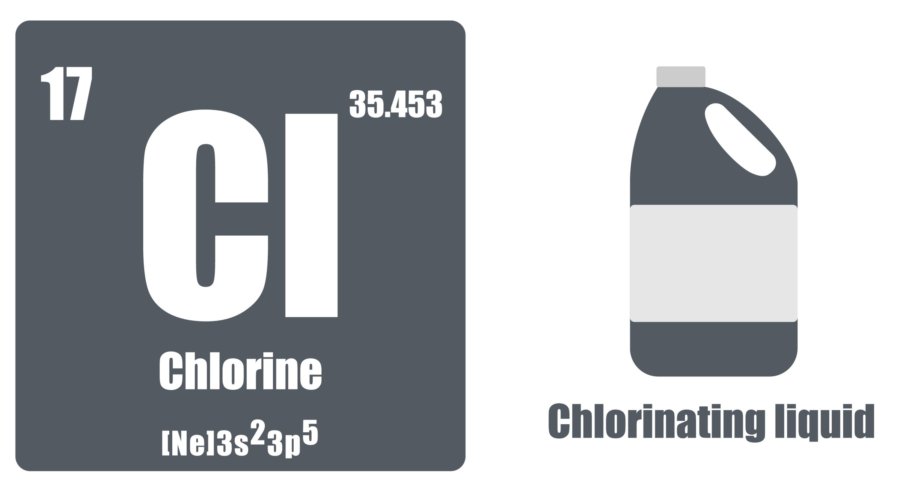

Ammonia wastewater is also treatable with chlorine (gas or hypochlorite), with simple equipment. Breakpoint chlorination is when there is sufficient chlorine to react with all present ammonia. Products include non-toxic chloramines, harmless nitrogen gas, and hydrochloric acid (wastewater becomes acidic).

Breakpoint chlorination is an excellent polish, removing virtually all ammonia and beneficially sanitizing the water. However, it requires appropriate safety training and equipment, and chlorine consumption is directly proportional to ammonia mass, so for some wastewaters, it can require large, expensive quantities of chlorine.

Because of relatively high operating costs, but low capital costs, it is best suited for low ammonia levels (e.g. < 50 mg/L NH3) or low flow rates (i.e. < 10 m3/day), especially when the need is periodic (e.g. 10% of the year).

Contact us with your ammonia wastewater chemistry, flow rates, and treatment goals to learn more.

Our SaltMaker modular evaporators and crystallizers turn almost any wastewater into clean water, minimal liquid discharge (MLD) brines or zero liquid discharge (ZLD) solids.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

Heavy industry, manufacturing, and natural resource-based industries often use large volumes of water and generate wastewaters requiring treatment. Saltworks designs, builds, and operates advanced wastewater treatment plants that economically and reliably treat tough industrial wastewaters.

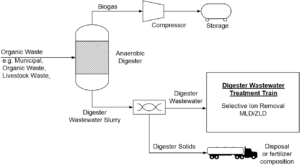

Digester wastewaters are by-products of biogas production in anaerobic digesters. They require treatment prior to disposal. To meet regulation compliance, treatment options range from minor interventions such as selective contaminant removal, to major interventions such as minimum and zero liquid discharge (MLD/ZLD).

Our wastewater treatment team can support biogas generation by helping you to assess and economically treat digester wastewater. We have solutions ranging from ammonia load reduction, to selective contaminant removal to closed-loop ZLD, and everything in-between.