FusionRO: An Inflection Point in Membrane Brine Concentration Technology

Background and implementation of ultra-high pressure reverse osmosis (RO) and nanofiltration (NF)

Nov 10th 2023 – Updated 15th July 2025

Article Highlights

- As of 2025, what was previously referred to as Saltworks’ OARO system is now called FusionRO (UHP RO/NF). It can achieve brine concentrations of >200,000 mg/L, enabling 50-80% higher brine concentration than ultra-high pressure reverse osmosis (UHP RO) alone.

- FusionRO is a series of ultra-high-pressure reverse osmosis (RO) and nanofiltration (NF) cascading loops. Both RO and NF are widely used in water treatment solutions.

- This combined UHP RO/NF process is similar to a process the industry loosely refers to as osmotically assisted reverse osmosis (OARO) but should not be confused with forward osmosis, as there is no draw solution.

- As of 2025, FusionRO is a commercialized Saltworks product, with plants sold to clients. It uses Saltworks’ Uni-RO modular system design coupled with standardized RO and NF membranes, elegant engineering, and intelligent automation.

FusionRO (UHP RO/NF) Overview

True osmotically assisted reverse osmosis (OARO) relies on non-commercial membranes and osmotic draw solutions to break osmotic pressure limits, whereas FusionRO uses standardized RO and NF membranes, arranged in ultra-high-pressure cascading loops with smart process controls to increase brine concentration >200,000 mg/L.

While often referred to in industry as “OARO” or “LSRRO,” Saltworks’ commercial solution is more accurately described as a hybrid ultra-high-pressure reverse osmosis and nanofiltration (UHP RO/NF).

FusionRO can achieve brine concentrations exceeding 200,000 mg/L of sodium chloride, compared to ~130,000 mg/L for standalone UHP-RO. This performance increase comes with added process complexity and energy input relative to traditional RO, but without the need for evaporators.

While the industry sometimes uses OARO and LSRRO interchangeably, FusionRO is a distinct, commercially deployed technology that does not require the osmotic mechanisms or membranes central to OARO.

Demand for FusionRO is driven by the system’s:

Ability to efficiently concentrate brines to ultra-high levels while keeping energy and operational costs manageable, offering a scalable and practical alternative to traditional thermal evaporation technologies.

- Use of membranes supplied by world-leading OEMs such as DuPont and Nitto Hydranautics, ensuring high-quality, professionally manufactured membrane components.

Incorporation of incremental process control innovations that reduce system complexity, enable hydraulic energy recovery, and protect and extend membrane lifespan.

- Proven applications across industries, including lithium extraction, mining wastewater treatment, chemical manufacturing, and zero liquid discharge (ZLD) systems.

How Does UHP RO/NF Work?

FusionRO utilizes standardized, commercially available reverse osmosis and nanofiltration membranes that operate under in cascading ultra-high pressure (1,800 psi) loops.

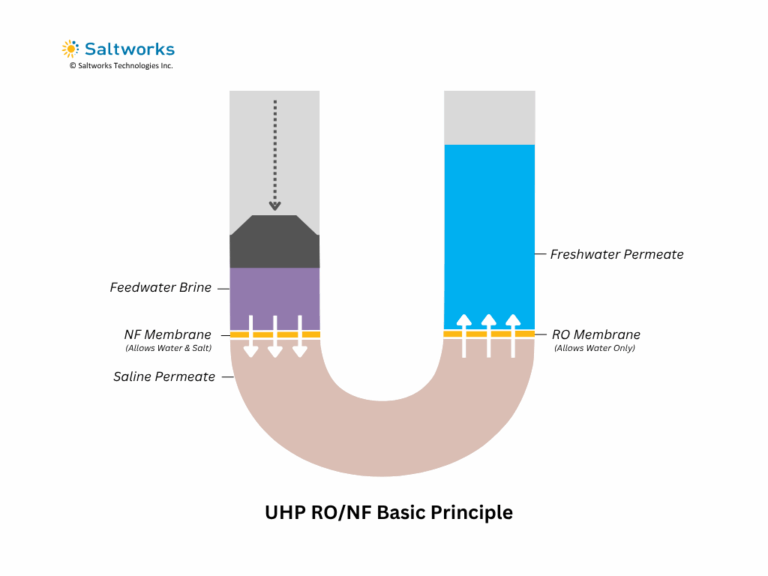

The mechanism of UHP RO/NF is illustrated in Figure 1 below, via a ‘textbook’ u-tube schematic. A ‘middle saline solution’ breaks the osmotic pressure into stages, enabling a higher final brine concentration through successive staging.

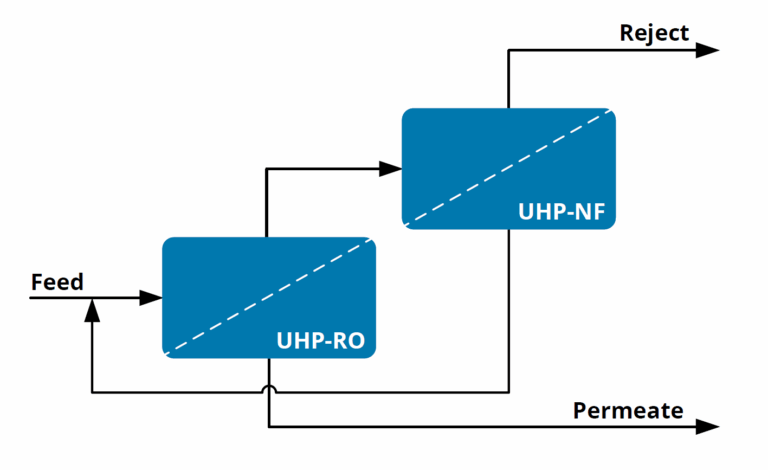

In the FusionRO system, the U-tube illustration is replaced with cascading RO loops as shown in Figure 2. The highest concentration loop concentrates the brine and passes both water and salinity to the ‘middle’ loop through an NF membrane.

While some literature refers to this process as OARO or low salt rejection RO (LSSRO), FusionRO is a distinct system based on commercially available, standardized RO and NF membranes arranged in ultra-high-pressure cascading loops.

The ‘middle stage’ salinated permeate produced by UHP NF serves two purposes. It enables the final stage brine concentration to increase via the use of commonly available pressurized RO equipment, albeit with a tailored NF membrane inside.

Secondly, it recycles its salinated permeate upstream to a more traditional RO-based pre-concentrator, which produces higher-quality RO permeate. This results in a membrane system capable of achieving significantly higher brine concentrations, at the added cost of process complexity.

Standardized RO and NF membranes are widely produced by qualified membrane OEMs, providing the supply security and process guarantees that customers and system integrators require.

Benefits of UHP RO/NF

FusionRO systems substantially increase brine concentration and compete with evaporator capacity.

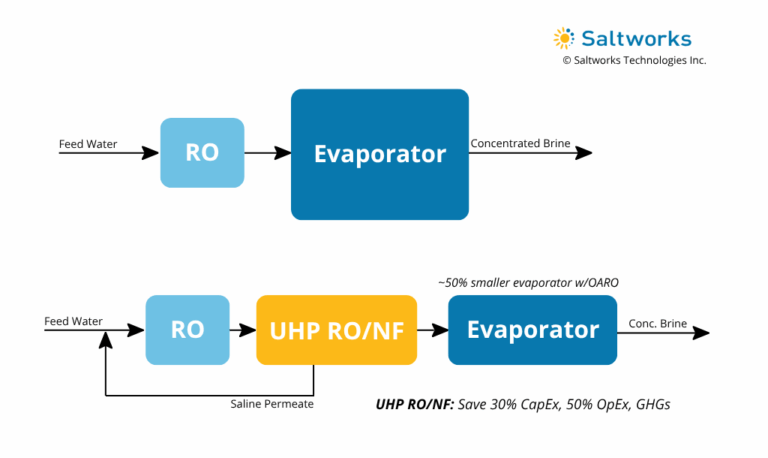

In fact, UHP RO/NF can decrease energy consumption by up to 50% with a 30% lower capital expenditure for the equivalent output by an evaporator. That said, the adoption of UHP RO/NF only makes economic sense for larger-scale systems where the inlet capacity is > 500 m3/day. Below this, the economics may not shoulder the added unit operation cost and operational intensity.

As shown below schematically, the incorporation of UHP RO/NF into a concentrating system can result in the need for a 50% smaller evaporator. In the case of lithium refining to lithium carbonate (Li2CO3), UHP RO/NF can eliminate the need for an evaporator, drastically increasing the value of the system. The positive economics of this technology grow with capacity.

UHP RO/NF vs. Evaporators: Challenges, Limitations & Considerations

While the use case for UHP RO/NF in lithium refining is difficult to argue against owing to the high purity and low scaling nature of the fluid being processed, the use case and results across other industrial feedwaters can vary.

As with all technologies, UHP RO/NF has limitations. Membranes, unlike evaporators, are more susceptible to irreversible fouling, scaling, and permanent damage through repeat chemical cleans.

In addition, as high brine concentrations are achieved through UHP RO/NF, the total dissolved solids ratio for contaminants and organics also increases. This exacerbates the risk of organic and biological fouling. Therefore, sound engineering and membrane health must be prioritized when considering UHP RO/NF. Capable firms build membrane protection, preservation, monitoring, and self-care into all their RO systems, making use of best practices, advanced diagnosis, trending, and self-cleaning technology as found in Saltworks’ XtremeRO and FusionRO platforms.

With membrane health considered, UHP RO/NF has a high potential to concentrate industrial wastewater including some cases from the oil and gas industry, where volume reduction and water recovery targets can be achieved with a lower-cost membrane system versus an evaporator.

That said, evaporators should not be ruled out. Bespoke and informed decisions should be made based on analysis and technical expertise. Evaporators offer more robust metallic heat and mass transfer surfaces and a simpler process than UHP RO/NF, in addition to higher brine concentration capabilities (albeit at an expense). Evaporators such as Saltworks’ SaltMaker employ further advantages as smart scale cleaning and descaling systems are built in.

In summary, there is no uniform decision on the best brine concentrator for industrial waters. Projects should consider an informed trade-off study between the options, including consideration of pilot testing if comparative data is not available. With that, factors such as capacity, feedwater chemistry, and pre-treatment processes must be examined by an expert when considering employing UHP RO/NF over an evaporator, or vice versa.

Saltworks' UHP RO/NF Developments

Despite OARO’s misunderstood reputation, Saltworks has demonstrated the ultra-high brine concentration capabilities of its UHP RO/NF technology through years of R&D, pilot testing, and full-scale implementation. With that, our experienced team of engineers and water experts has established a simplified, standardized, and repeatable full-scale design for UHP RO/NF.

Saltworks’ FusionRO can achieve brine concentrations >200,000 mg/L through cascaded RO and NF membranes. In addition, our intelligent modular systems are scalable and incorporate optimization monitoring and control systems.

Our UHP RO/NF systems can also seamlessly integrate with additional Saltworks solutions and even externally produced systems.

For example, pairing FusionRO with Saltworks’ BrineRefine removes scaling ions to reach even higher brine concentrations, and coupling with intelligent automation enables dynamic recovery control through real-time scaling sensors.

Saltworks’ BrineRefine and XtremeRO Units at Saltworks’ HQ

To conclude, UHP RO/NF is not the “new kid on the block” but it does stand as a turning point for concentrating and refining technology. FusionRO is a novel arrangement of proven components already widely available in the industrial supply chain, implying a short road to full commercialization at cost competitiveness.

And, while fouling and membrane health still limit the tech’s ability to deal with harsher feedwater, innovation across the sector should result in more resilient systems in the near future. But for now, careful consideration of feedwater chemistry and pre-treatment options is key to an energy-and-cost-efficient UHP RO/NF system.

Considering FusionRO?

The Saltworks team is pleased to offer full-scale FusionRO systems, pilot testing, and analysis to qualified customers. Reach out to speak with our experts and optimize your brine today.

About Saltworks

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.