SaltMaker AirBreather Evaporator Crystallizer

Open-to-atmosphere evaporator, operating at low temperatures to concentrate brine.

Oct 15th 2018

Saltworks originally developed the SaltMaker MultiEffect—the AirBreathers’ older ‘cousin’—in partnership with Canadian oil sands companies. They were seeking to use waste heat thermal energy to treat challenging heavy oil blowdown water. The industrial end users set out the following criteria:

Saltworks answered this challenge with the SaltMaker MultiEffect. It replaced steam and scaling heat transfer surfaces with an air humidification-dehumidification cycle, which evaporates and condenses water in successive effects. Clean water is produced by each effect, with the final effect open to atmosphere to cool the plant. The machine is designed to remain scale-free.

After having completed shale field pilots of the SaltMaker MultiEffect, the team realized that a better configuration existed for shale: leveraging waste thermal energy with an open to atmosphere evaporator that can manage volatile risk. Capacity improved four times per unit of equipment. However, thermal energy also increased four times. As engine jacket cooling water or low-cost gas may be available, this is less of a barrier in shale.

Open evaporators release water vapor to atmosphere, so there is no condensed water to manage. However, evaporating water requires a lot of energy: 2400 MJ per tonne. In addition, produced water includes more than just water. It includes salt that can scale and corrode the plant, and toxic volatiles such as benzene or ammonia that can pollute the atmosphere or cause health problems. The AirBreather overcomes both challenges through innovation.

Up until recently, most open evaporators were of the submerged combustion type. Combustible gas and compressed air are injected into a large “kettle boiler.” Combustion occurs underwater and heat is transferred directly to the salty water. Water is concentrated, and vapor is released, often resulting in a tall plume rising through the sky. These large kettles must be metallic to withstand combustion temperatures, while also made of exotic materials to reduce corrosion risk related to high salinity. Emissions must also be managed since combustion is involved. Other open types may heat the water making use of direct contact with exhaust gas, or heating via a heat exchanger. Regardless, volatile emissions can still emerge.

The AirBreather overcomes this avoiding any contact of the wastewater with air. The evaporation chambers are 100% sealed from the atmosphere. We provide customers with two options: return freshwater fit for surface discharge, or reduce volume by sending only clean water to atmosphere. How we do this is a proprietary secret that we will release to customers under NDA.

When developing the AirBreather, we aimed to pack extremely high evaporation capacity into a small repeatable module. Every AirBreather AB-100 consists of 4 evaporation modules, packaged into ISO container frames. The entire plant is built around ISO container frame modules, for ease of delivery, installation, and expansion to suit project needs. The “100” in AB-100 stands for 100 tonnes/day of produced water volume reduction (600 barrels per day or 26K GPD). Larger plants can be built by simply adding AB-100s, allowing customers to grow their volume reduction capacity over time.

Evaporating water is easy; however, managing volatiles and achieving extremely high brine concentration or solids production to realize zero liquid discharge presents new challenges.

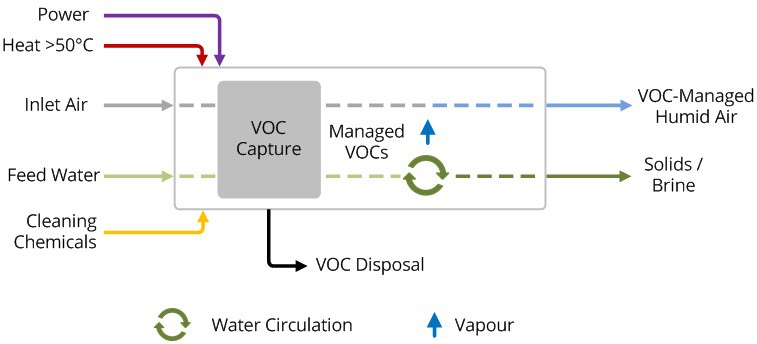

Wastewaters can contain substances with low boiling points that will evaporate with water. Examples include ammonia, or volatile organic compounds (VOCs) such as methanol, BTEX, and others. Odor may also impact neighbours. The AirBreather’s proprietary “Volatile Management System” prevents volatiles from atmosphere contact so that only safe, clean, low-temperature water vapor is released. Our pilot plants are outfitted with this same system, so we can prove the operations at your site, or ours on shipped water.

As saltwater is concentrated, scale can precipitate, solid salt plugs can form, and high chloride levels will corrode metallic parts. The SaltMaker AirBreather borrows SaltMaker MultiEffect technology to overcome these challenges, resulting in the first open-to-atmosphere evaporator that squeezes every last drop of liquid waste down to a solid by-product or achieves any desired brine concentration along the way. This is accomplished by:

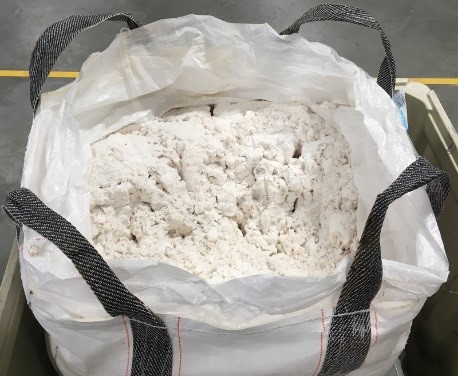

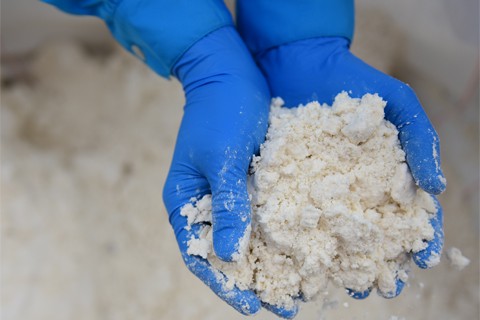

Samples of solids as produced and discharged to an automated bagging system

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Open-to-atmosphere evaporator, operating at low temperatures to concentrate brine.

There are four fundamental types of industrial evaporators and crystallizers used for wastewater treatment, brine management, or improving water reuse. Lower your risks and improve costs by understanding the trade-offs between the different evaporator types.

Scale is a crust that forms on membranes, heat transfer surfaces, and on the inside of pipes as salts precipitate out of solution. It blocks flow, disrupts heat transfer, and increases energy requirements for water treatment systems

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).