EPRI Publishes Report: Successful FGD Industrial Water Reuse

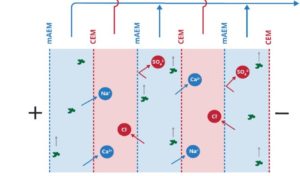

Saltworks welcomes a new report by the Electric Power Research Institute (EPRI) summarizing results from a pilot completed at a large coal power plant in the US. FlexEDR monovalent electrodialysis reversal treated FGD wastewater, recovering 93% freshwater.