SaltMaker MVR & MSF Evaporative Crystallizers

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

Saltworks » Applications » Lithium Extraction and Refining Systems

Most of the world’s battery-grade lithium is produced by:

A third method is gaining popularity, particularly in North America and China:

Direct lithium extraction (DLE) operators generally extract lithium using methods unique to each site, but most produce a lithium chloride solution of 1,000 to 2,000 mg/L containing impurities. We add value for clients downstream of customer-selected DLE processes where we help by concentrating lithium chloride solutions and converting them to battery-grade lithium solids.

We offer comprehensive modelling, piloting, and full-scale solutions that convert DLE outputs into battery-grade inputs.

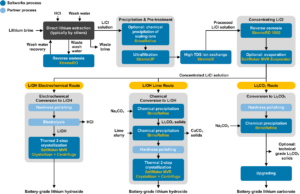

Lithium processing plants are water plants. They refine a high-grade lithium output using water that can be returned and re-used. The steps generally include concentrating a brine, chemical conversion steps to change the lithium form, washing, and final crystallization.

Saltworks offers solutions for every step, including comprehensive “concentrate, refine, and convert” packages. Our solutions can remove troublesome ions such as silica, thereby enabling higher recovery processing in membrane systems.

Then, our next-generation reverse osmosis (RO) system, XtremeRO, concentrates lithium chloride (LiCl) up to 50% higher than conventional RO. These ultra-high pressure (1,800 psi) reverse osmosis (UHP-RO) systems reduce downstream evaporator size and cost and in some cases remove the need for them entirely.

To ensure the highest lithium quality and yield, we precisely target impurities and selectively precipitate the lithium forms most valuable to a project. We pair smart, precise chemical conversion (BrineRefine) with robust ceramic ultrafiltration (XtremeUF) to complete conversion steps with less chemical waste and greater precision, all delivered in an automated, compact package with integrated controls.

Our SaltMaker evaporator crystallizers concentrate lithium brines and crystallize solid, battery-grade lithium solids. Built-in self-cleaning ensures reliability at optimal capacity, while producing high-purity solid product. Learn more in our SaltMaker MVR lithium crystallizer spec sheet.

We also reduce the need for—and size of—evaporation steps, saving valuable energy and capital costs. To learn more about efficient refining of high-quality lithium, download our lithium brochure, check out our article, or contact our expert lithium team.

Learn more about the Lithium Test Centre: in-house mini-refineries staffed by experts.

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

This lithium process flow brochure shows how membrane, thermal, and chemical water technologies fit into various stages of lithium production. Learn how to process lithium to battery-grade, downstream of direct lithium extraction.

Saltworks is pleased to announce the production of battery-grade lithium hydroxide from an industrial wastewater. Saltworks’ process harvests lithium hydroxide solids that reach or exceed battery-grade specifications.

Saltworks is delighted to formally announce its Lithium Test Centre, dedicated to accelerating and de-risking lithium processing projects. The new centre incorporates end-to-end lithium processing pilot plants and technical expertise in the production of battery-grade lithium chemicals.

Saltworks is pleased to release a new technology map for achieving complete system ZLD and LCE production. Saltworks’ CEO, Ben Sparrow, also covered the same topic on the “(Don’t) Waste Water” podcast, hosted by Antoine Walter.