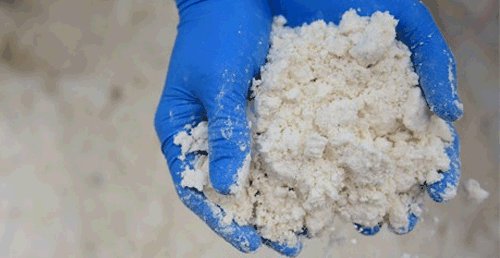

SaltMaker ChilledCrys Crystallizer

ChilledCrys is a novel and highly competitive alternative to expensive evaporators for zero liquid discharge of specific chemistries.

Evaporators and crystallizers serve two important roles:

Our SaltMaker evaporator crystallizers process challenging industrial brines without complex pre-treatment thanks to their self-cleaning and forced circulation designs. They are engineered to withstand corrosion, minimize site installation costs, and maximize uptime through robust design and intelligent automation.

Whether you need concentration and minimal liquid discharge (MLD) with an evaporator, or salt crystallization and zero liquid discharge (ZLD) with a crystallizer, there is a SaltMaker suited to your project’s treatment goals.

Our SaltMaker® family of services provides scalable, flexible solutions that cover all evaporation and crystallization needs, including recovery of valuable metals, and MLD and ZLD.

We offer solutions across five categories, each of which has different advantages for different projects. These technologies are then tailored to specific end-user needs and energy sources.

We help you to achieve the optimal solution for your project by providing early consulting and engineering advice up to full process design integration with project assets. We also provide a range of bench and pilot testing services and ongoing project support.

| SaltMaker Product | SaltMaker MultiEffect | SaltMaker AirBreather | SaltMaker MVR | SaltMaker MSF | SaltMaker ChilledCrys |

| Evaporation Process | Multiple effect humidification dehumidification (HDH) | Single effect humidification (open), with optional dehumidification (HDH) | Mechanical vapor recompression (MVR) | Multistage flash (MSF) | Salts formed by eutectic crystallization. Not an evaporator. |

| Primary Energy Source | Thermal energy ~90°C | Thermal energy ~60–90°C | Electrical power | Thermal energy > 85°C | Electrical power |

| Carrier Gas | Humid air | Humid air | Sub-atmosphere steam (30 kPa) | Sub-atmosphere steam (30 kPa) | No carrier gas. Cooling a warm brine crystallizes salts. |

| Solid Salt (ZLD) or Brine Concentrator (MLD) | MLD | MLD | ZLD or MLD | ZLD or MLD | ZLD or MLD |

| Atmospheric Air Contact | None | Optional | None | None | None |

| VOC Management | Post-treatment of distilled water | Built-in | Post-treatment of distilled water | Post-treatment of distilled water | Not generally applicable |

| Use Case | Thermal energy >$5/GJ | Thermal energy <$5/GJ | Electrical power available, lower cost than steam equivalent | Low cost steam available | Feed fluid has rapid solubility-temperature changes |

| Notes |

|

|

|

|

|

* Challenging water chemistry typically means high in organics and/or scaling ions. Saltworks’ other technologies such as XtremeUF and BrineRefine address challenging chemistry upstream of evaporators & crystallizers.

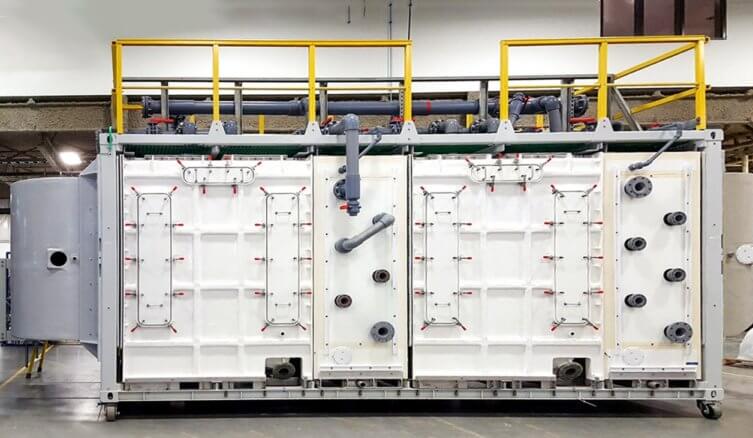

The SaltMaker evaporator-crystallizer family is engineered to meet diverse needs while integrating safety-by-design. Each system is built to maximize uptime through sound engineering to reduce scale, remove corrosion risk, and self-clean during operation.

Scalability and ease of installation and operation is at the heart of every SaltMaker. All four SaltMaker products are constructed using modular ISO shipping container building blocks and are available in different sizes, with configurable options for your application.

Every brine presents unique challenges, and our engineers are ready to review yours. The best solution may involve a cost-optimized blend of technologies. As a manufacturer of membrane, thermal, and chilled concentrators Saltworks is uniquely positioned to optimize treatment economics for the lowest total cost of ownership.

Contact us for an assessment. Find out what SaltMaker will work best for you and explore upstream membrane concentration options for superior economics.

ChilledCrys is a novel and highly competitive alternative to expensive evaporators for zero liquid discharge of specific chemistries.

Achieve true ZLD with two forced circulation evaporative crystallizer options: SaltMaker MVR and SaltMaker MSF.

Open-to-atmosphere evaporator, operating at low temperatures to concentrate brine.

The SaltMaker MultiEffect is an industrial evaporator crystallizer that reduces brine volume, even to zero liquid discharge (ZLD).