Landfill leachate is a foul-smelling wastewater generated when water trickles down through buried solid wastes. Landfill leachate contains a wide range of pollutants, such as ammonia, heavy metals, organic matter, personal care and pharmaceutical chemicals, pesticides, per- and

polyfluorinated substances (PFAS), total dissolved solids (TDS), and many more. In many jurisdictions, landfill leachate is prohibited from discharge into a public sewer without treatment. However, landfill leachate can be treated to meet regulation guidelines for safe discharge into an aquatic environment.

Existing landfill leachate treatment generally integrates the following options:

- physical-chemical (phys/chem) treatment using adsorption, air-stripping, flotation, coagulation/flocculation, chemical precipitation, membrane separation (ultrafiltration, nanofiltration, and reverse osmosis), and advanced oxidation;

- biological treatment method using anaerobic, aerobic and anammox treatments; and

- evaporation using mechanical vapor recompression and submerged combustion evaporation.

When landfill leachate must be treated to meet surface water discharge quality, reverse osmosis (RO) is the best available technology. RO offers an absolute separation barrier for all pollutants, more compact footprint and greater automation over other options. A final polishing step after RO can remove any trace volatile organic compounds (VOCs) and ammonia that may slip through the RO membrane into the permeate.

RO however also has two disadvantages for landfill leachate: membrane fouling and high disposal cost for a large volume of RO leachate brine. RO with unique modules such as disc-tube RO (DTRO) has claimed to address the membrane fouling issue to a certain degree. DTRO equips larger feed channels than existing spiral wound RO. During operation, landfill leachate is recirculated in DTRO module under high turbulence and crossflow to clean membrane surface. However, active membrane area of DTRO is much smaller than that of a spiral wound RO. DTRO requires a big footprint and high energy consumption with excessive brine recirculation. Operators also allege that DTRO require frequent cleaning maintenance and internal rebuilds. DTRO has not addressed the RO brine issue. The RO brine is usually about 20 – 40% by volume of the original leachate depending on the leachate chemistry. RO leachate brine is oftentimes disposed by evaporation, incineration, advanced oxidation,

and/or solidification/stabilization, which are energy intensive and with high cost.

Recent technology and process breakthroughs in desalination can help address both RO disadvantages while treating landfill leachate. There are several emerging commercial versions of ceramic membrane modules (for example,

XtremeUF) that enable foulant removal pretreatment and the use of commoditized spiral wound RO for wastewaters with heavy foulants (for example,

produced water from oil/gas production). Ceramic membranes are long-lasting, fouling-tolerant, and easy to clean. After many competitive suppliers entered the ceramic membrane market, membrane costs lowered tremendously over the years. As for RO brine volume reduction, a membrane concentrator, which uses a process of ultra-high-pressure RO (for example,

XtremeRO) in conjunction with scaling-removal chemical softening (for example,

BrineRefine), can now further concentrate RO brine up to a TDS of 140,000 mg/L, around double the upper TDS limit of existing spiral wound RO.

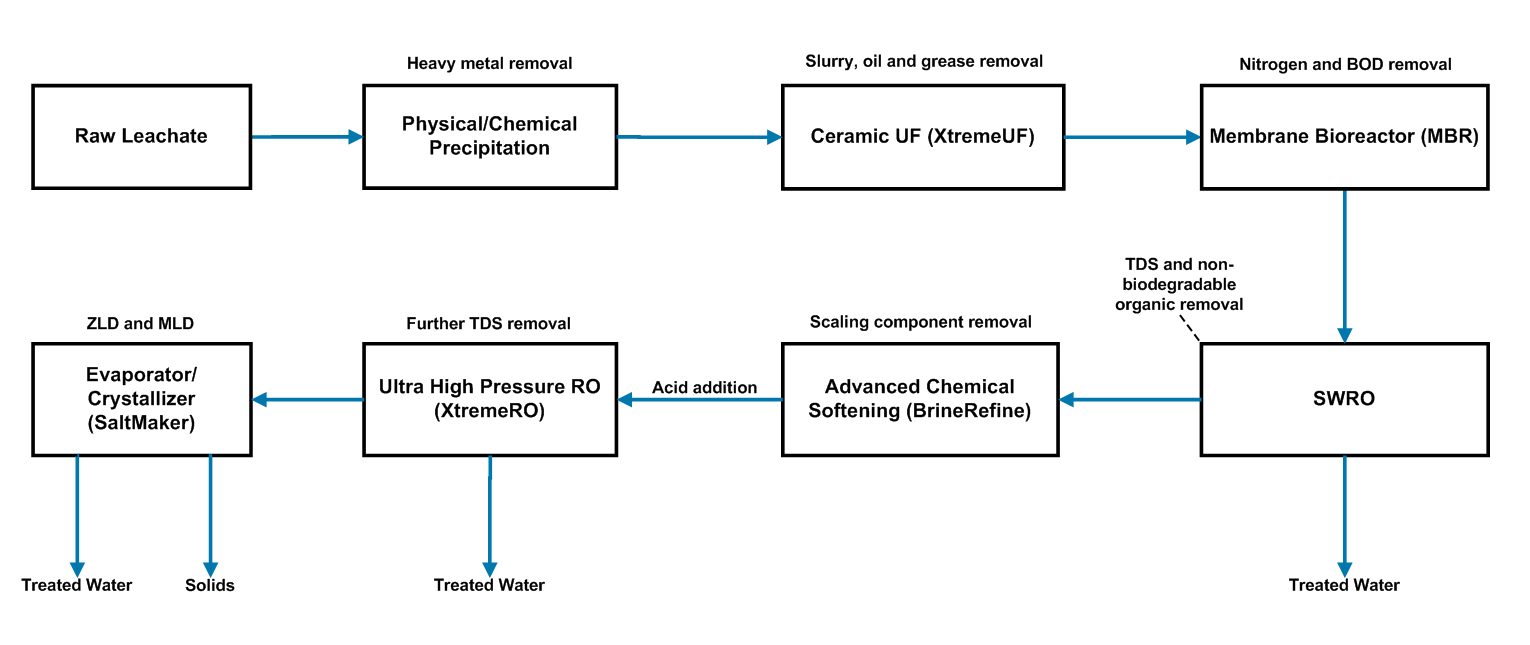

Saltworks developed a more cost-effective solution for landfill leachate. The solution integrates three recent breakthrough water treatment technologies with four existing options: phys/chem treatment, XtremeUF, membrane bioreactor (MBR), Seawater RO (SWRO), BrineRefine, XtremeRO, and evaporation. Each step addresses a specific pollutant in landfill leachate to deliver an optimized treatment train. The process flow diagram presented in Figure 1 shows all steps to provide a comprehensive view to the reader. Some steps are optional, depending on specific project requirements.

Saltworks engineers can review specific projects to deliver the balance of a simple but cost-effective treatment train.