Saltworks has delivered a complete zero liquid discharge (ZLD) industrial desalination solution to a mining site in the US. The uniquely modular and digitized plant enabled the client to rapidly install and implement the intelligently automated ZLD system with reduced inputs.

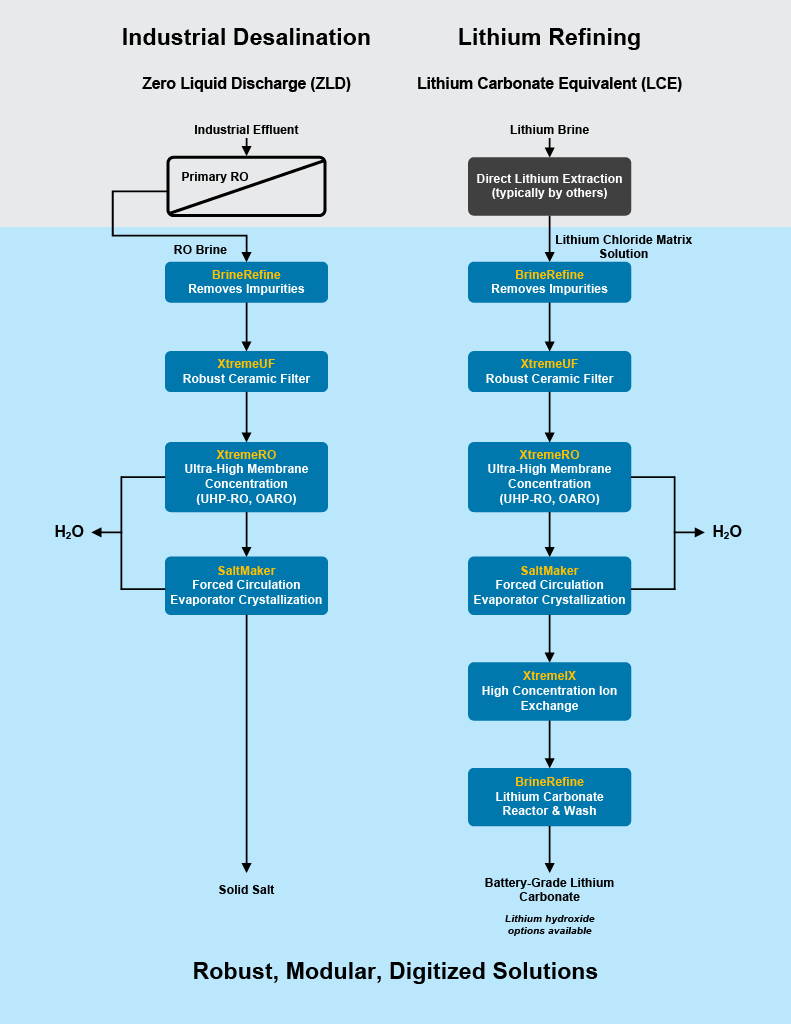

For cost-optimized ZLD, most projects need an ideal blend of membrane, chemical, and thermal stages to minimize costs, maximize freshwater recovery, and reduce waste products. Saltworks’ innovative, modular, and digitized products operate as standalone units or can be packaged together into a complete system.

The delivered plant integrates BrineRefine, XtremeUF, XtremeRO, and SaltMaker MVR for optimized performance and costs. In Saltworks’ ZLD solutions, each technology is delivered on a compact skid, fully equipped with controls and support systems for quick deployment and easy installation at the client’s site. All interconnections and digital controls are provided, further accelerating installation, start-up and lowering integration costs.

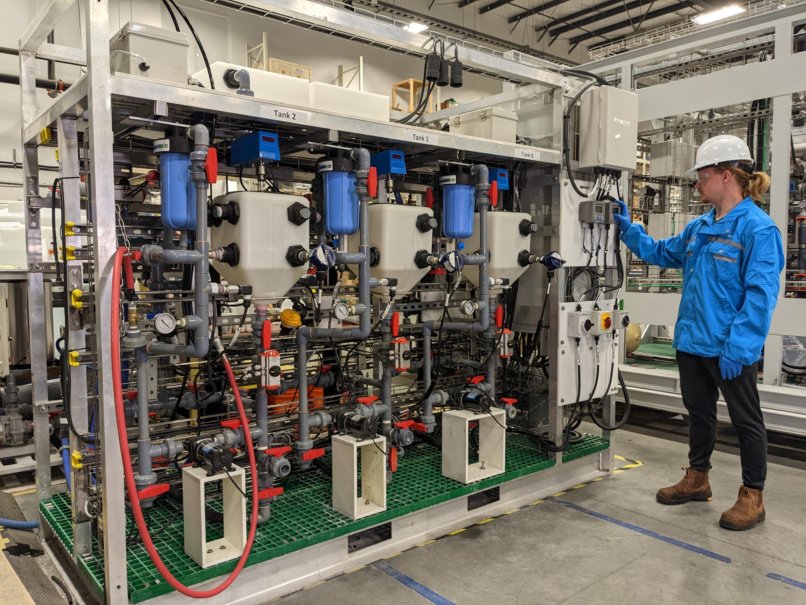

The XtremeRO unit with a Saltworks team member during manufacturing at the Saltworks factory.

To optimize cost and energy use, maximizing reverse osmosis (RO) system recovery is key. This requires protecting RO units from scaling and fouling as higher concentrations are reached. Because the initial wastewater feed is saturated in scaling ions, Saltworks’ BrineRefine continuous stirred tank reactor (CSTR) first precipitates out solids, then allowing our XtremeUF ceramic ultrafiltration unit to reject the resulting sub-micron precipitants.

This process protects the downstream XtremeRO high-pressure reverse osmosis system, which recovers more water and produces a high-concentration, low-volume brine. Finally, a SaltMaker MVR thermal evaporator-crystallizer concentrates even further and produces zero liquid discharge solids.

Saltworks’ standardized, repeatable, and digitized modular plants are available to serve your industrial desalination or lithium refining projects.

The SaltMaker MVR unit with a Saltworks’ technician during manufacturing at the Saltworks factory.

Considering a zero liquid discharge solution? Contact our team today to take advantage of our pioneering expertise in ZLD, process optimization, engineering, and manufacturing.

About Saltworks

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Related Resources

Mining Water for Lithium: ZLD and LCE

Saltworks is pleased to release a new technology map for achieving complete system ZLD and LCE production. Saltworks’ CEO, Ben Sparrow, also covered the same topic on the “(Don’t) Waste Water” podcast, hosted by Antoine Walter.

ZLD Without Evaporation: Saltworks Achieves First ZLD With a Membrane Crystallizer

Saltworks’ engineers achieve ZLD without conventional energy-intensive boiling through a novel membrane-chiller and UHP-RO hybrid plant for a mining client.

RO Brine Treatment: Why Maximizing Reverse Osmosis Recovery Matters

Treating RO brine optimally begins with utilizing lower-cost membrane systems to minimize volume for downstream processing. Clients must then decide between the available thermal treatment options that allow for brine concentration or treating down to solids for disposal.

What is Zero Liquid Discharge & Why is it Important?

Zero liquid discharge (ZLD) is an engineering approach to water treatment where all water is recovered and contaminants are reduced to solid waste.