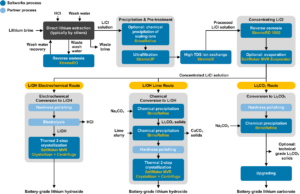

In 2024, Saltworks focused on installing full-scale lithium recovery systems in battery plants while developing novel solutions the lithium extractive industry needs. In the extractive space, Saltworks focused on enabling lower-cost direct lithium extraction (DLE) through robust and cost-effective methods to pre-condition upstream of DLE and to concentrate, refine, and convert (CRC) DLE eluates into battery chemicals.

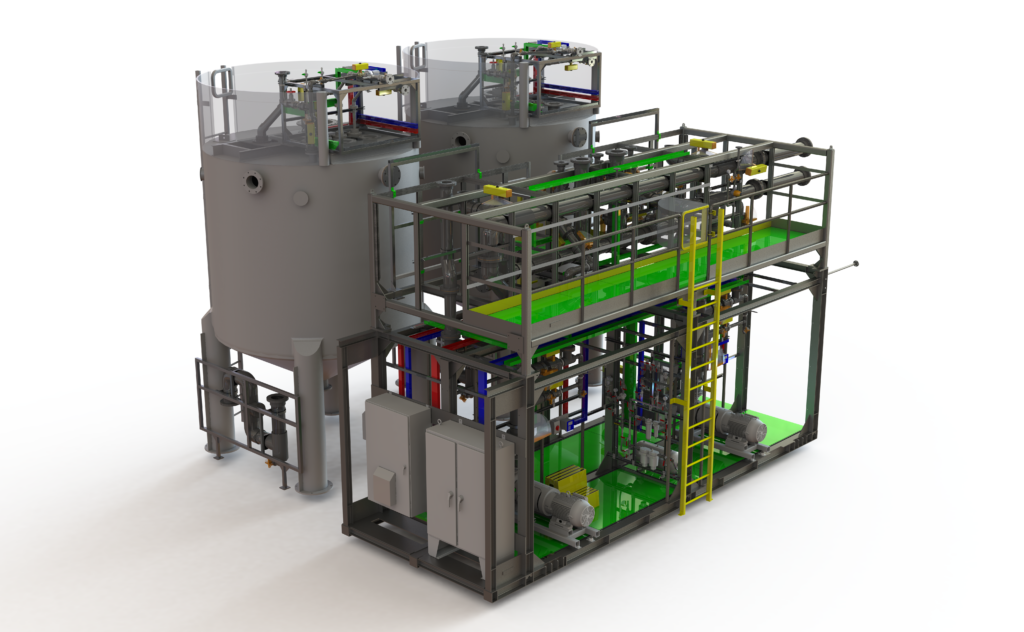

Innovative advancements that help push DLE-based refining systems down the cost curve were generously supported by Canada’s National Research Council IRAP program and Natural Resources Canada. Our simplified flow sheet using a novel reactor consistently produced battery-grade lithium carbonate across multiple DLE pilot projects.

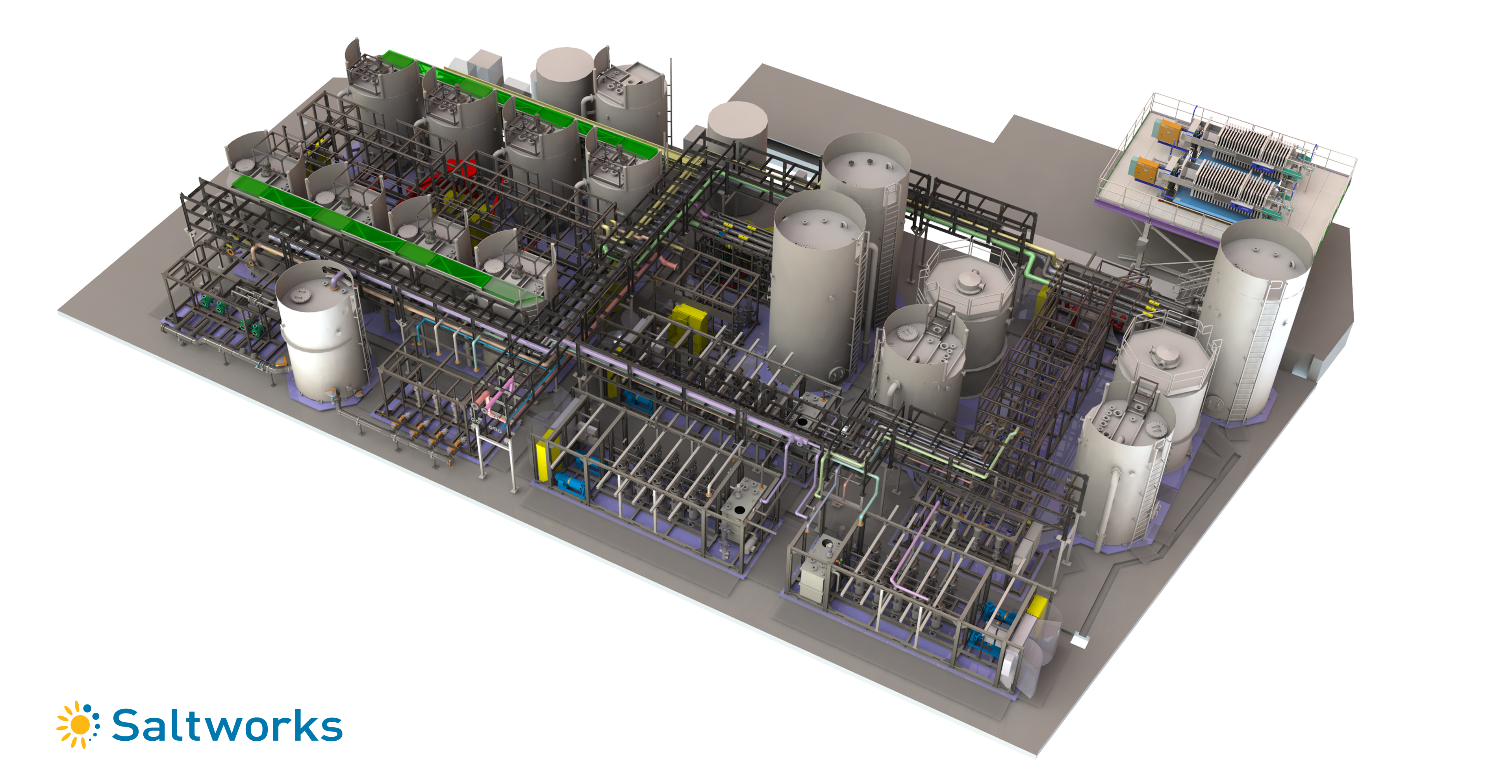

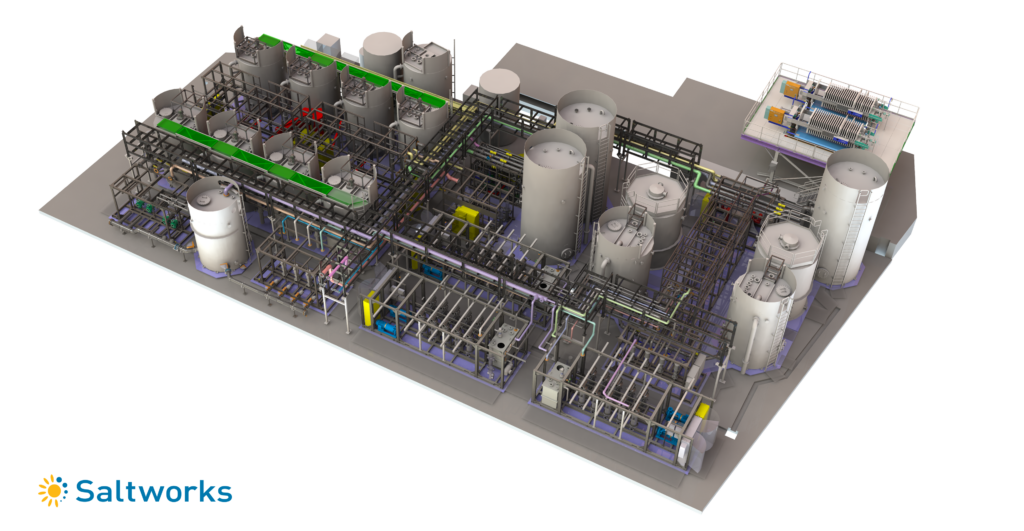

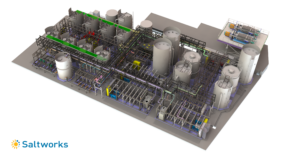

We proudly advanced a front-end engineering design (FEED) study for a commercial-scale DLE-based lithium refining facility in North America. This study resulted in detailed engineering designs and a firm price, enabling a clear path to commercialization. Additionally, our larger-scale ‘PILOT 10’ lithium refinery achieved significant milestones, including producing drums of battery-grade lithium carbonate from EMP Metals’ resource, as discussed in their December 2024 press release.

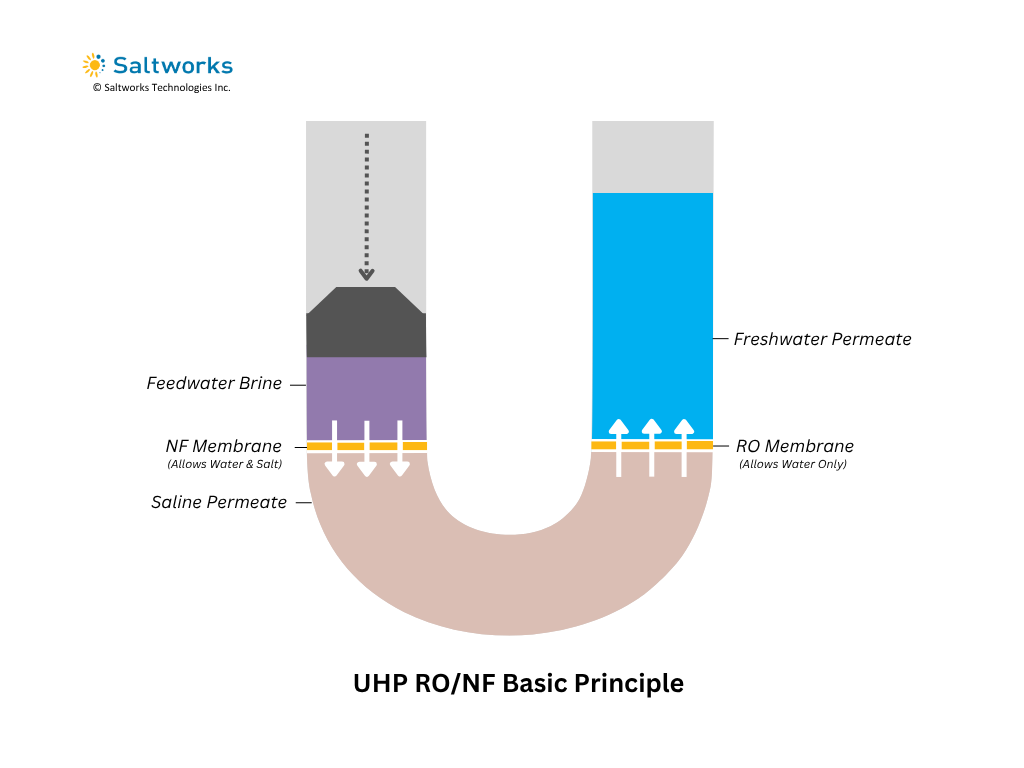

Saltworks secured its first commercial order for its ultra high-water recovery (UHP RO/NF) technology with a world-leading lithium producer. Despite suppressed lithium prices, we collaborated with industry leaders to innovate and improve refining technologies, achieving a 25% reduction in total cost of ownership with the potential for an additional 15% reduction.

In 2025, Saltworks will continue to offer our commercialized technologies and services to DLE projects. We will also continue to invest in innovation to advance lithium refining technologies that enhance DLE’s competitiveness.

Contact one of our engineers today for more information on how Saltworks can support your lithium project.

About Saltworks

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Related Resources

Lithium Brine Extraction Technologies & Approaches

Explore commercial sources of lithium and advanced technologies for extracting lithium from hard rock and brine resources.

XtremeUF Ceramic & Polymeric Ultrafiltration

XtremeUF ceramic and polymeric ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

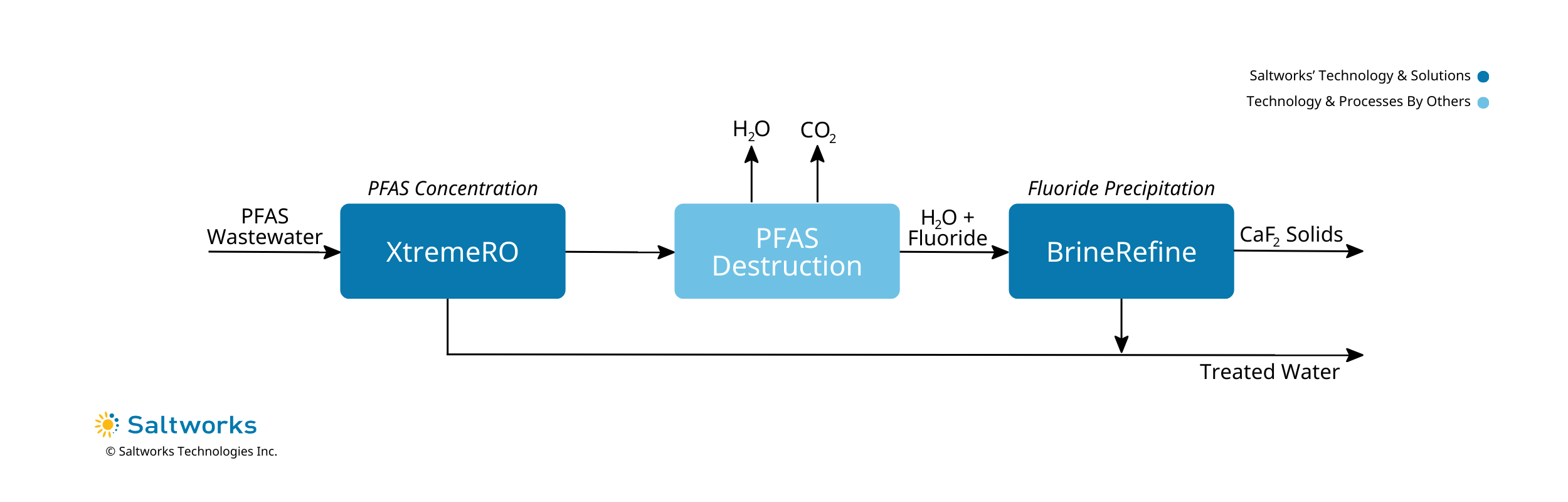

Saltworks Triples BrineRefine Capacity to Support Semiconductor and Battery Industries

Saltworks successfully delivered a 3x scaled-up BrineRefine plant to a major semiconductor plant in the USA. This new product offers significantly increased capacity, 3000-4500 m3/day, while maintaining the original 1000-1500 m3/day system’s fully modular design.

Semiconductor Firm Chooses Saltworks’ Off-Site Constructed and Commissioned Solution

Saltworks Technologies is pleased to announce an award of a 600 GPM advanced hydrofluoric acid wastewater (HFW) treatment plant for a prominent U.S. semiconductor manufacturer.