Saltworks was named to the 2017 Global Cleantech 100. This prestigious list, published by the Cleantech Group, identifies companies with the most innovative and promising technologies poised to make a significant impact in the cleantech sector.

Over 9,900 nominations from 77 countries were reviewed by the group’s expert panel.

The announcement at the 2017 Cleantech Forum in San Francisco comes on the heels of several major advancements at Saltworks.

Saltworks completed a third repeat order to a major US industrial firm, installed a full-scale SaltMaker for a Canadian customer, and successfully treated highly scaling coal-fired powerplant wastewater from a major utility with their Salt Splitter technology.

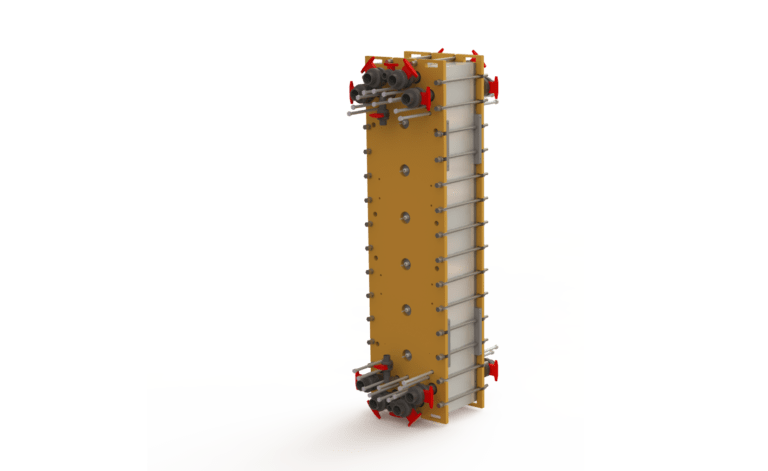

Saltworks’ systems treat highly challenging wastewaters to recover freshwater, reduce waste and enable reliable zero liquid discharge (ZLD), and recover by-products of value.

“Saltworks is honoured that the Cleantech Group recognized our significant accomplishments in 2016 and the impact we will continue to make in 2017. The acknowledgement comes at a great time as we are both fulfilling repeat commercial orders and advancing innovative next-generation desalination and water treatment solutions,” said Mitchell Frank, Saltworks’ Manager of Business Development & Marketing.

About Saltworks

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Related Resources

ESG and Industrial Water: What Should Corporate Leaders Focus On?

Water plays a critical role in ESG performance for many companies. With growing concerns around pollution ands consumption of water and energy, investing in responsible water management technology can improve your ESG profile and reduce operational risks.

Modern Chemical Softening to Maximize RO Recovery: Scale Removal

With the growing importance of brine management, modernized chemical softening systems can enable economic ultra-high recovery reverse osmosis, minimizing RO brine volume, disposal costs, and reliability risks.

How to Manage Brine Disposal & Treatment

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).

What is Zero Liquid Discharge & Why is it Important?

Zero liquid discharge (ZLD) is an engineering approach to water treatment where all water is recovered and contaminants are reduced to solid waste.