Announcing ScaleSense

Optimizing existing water treatment assets is the lowest cost path to incremental water production and reducing residual waste. However, many of the tools needed had not been developed—until now.

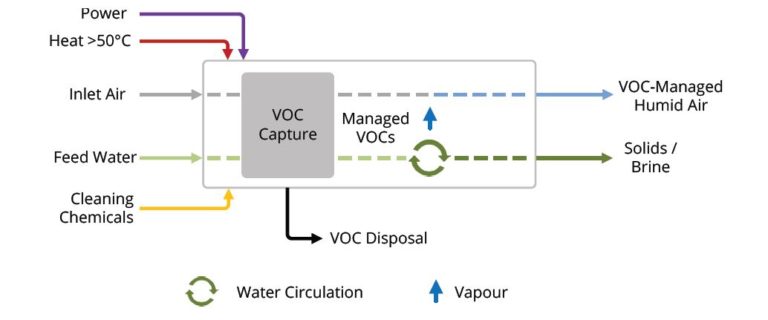

Saltworks announces ScaleSense: our real-time, ion-specific sensor that works on saline waters, i.e. brines. By measuring scaling species live, ScaleSense enables users to optimize processes in real time as conditions change—without the need for human intervention, lab work, or guesswork.

ScaleSense Applications

With ScaleSense, it is now possible to lower capital and operational expenditure by:- Running reverse osmosis systems closer to their peak recovery and automatically changing that recovery as inlet water chemistry shifts, without putting membranes at risk or generating surplus brine.

- Operating cooling towers at higher cycles, saving water usage and reducing blowdown.

- Optimizing chemical loading and sludge production of chemical softening systems

- Partially bypassing and blending sulfate treatment processes

Measure Scaling Species in the Toughest Waters

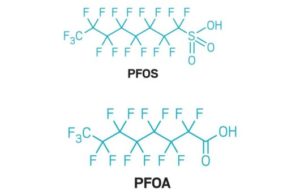

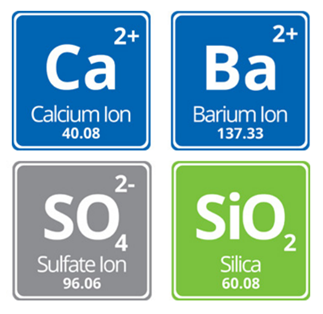

ScaleSense can measure calcium (Ca2+), barium (Ba2+) or sulfate (SO42‑) ions, or silica (SiO2), in real-time and with repeatable accuracy. It can also measure TDS in extremely concentrated brines, where traditional conductivity meters flatline.

Check out our ScaleSense homepage to see sample use cases. We can package ScaleSense with our process engineering and control services, to enable customers to increase their plant smarts, improve recovery, uptime, data, and reduce waste.

Can you imagine a use for ScaleSense? Do you think you have incremental water “left on the table” that can be recovered? Contact us and let us figure it out.

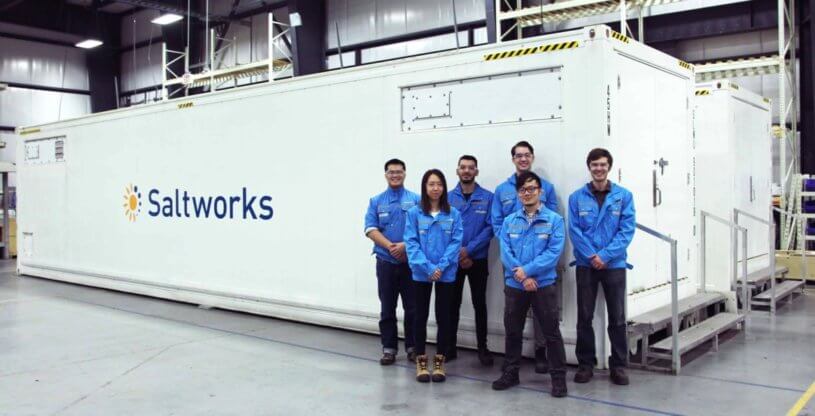

About Saltworks

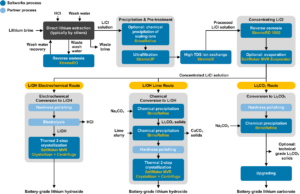

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Related Resources

99% Membrane System Recovery on Scaling Cooling Tower Blowdown

Reverse osmosis-based brine concentrators are reaching new performance levels not seen before. Saltworks is pleased to report that a substantial pilot plant is currently demonstrating 99% freshwater recovery on cooling tower blowdown (CTB).

Real-Time Sensing and Process Control: Introducing ScaleSense

Real-time measurement provides prompt feedback for controls. A real-time sensor can help to optimize your process, reduce risk, and minimize operational and maintenance demand. Saltworks has developed a new real-time sensor—that is simple and robust—to operate in the high-TDS range.