Anaerobic Digester Wastewater Management During Biogas Production

Targeted and comprehensive solutions

Apr 28th 2020

Key Takeaways

- Digester wastewaters are by-products of biogas production in anaerobic digesters and require treatment prior to disposal. To meet regulation compliance, treatment options range from minor interventions, such as selective contaminant removal, to major interventions, such as minimum and zero liquid discharge (MLD/ZLD).

- Ammonia in digester wastewaters can be selectively removed by stripping, biological treatment, and chemical methods. Selection of options requires careful consideration of local conditions, energy sources, economic usability of the end-products, and most importantly the specific wastewater chemistry, such as ammonia concentration and co-contaminants (e.g. bicarbonate, phosphate, organics, and metal ions).

- An experienced wastewater treatment team can help you to review and economically assess the treatment options for digester wastewater, from selective contaminant removal to closed-loop ZLD, and everything in between.

Anaerobic Digesters & Wastewater

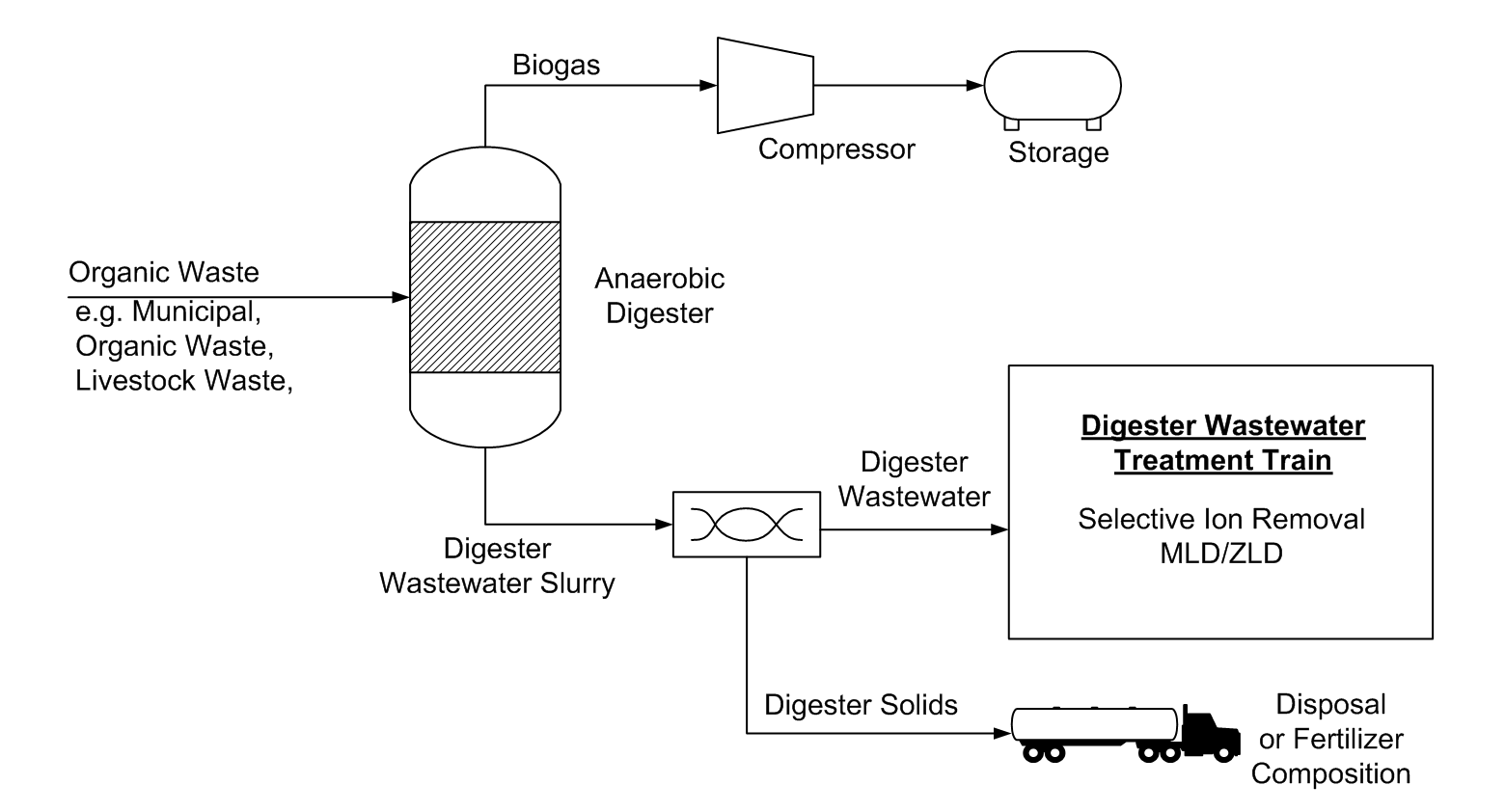

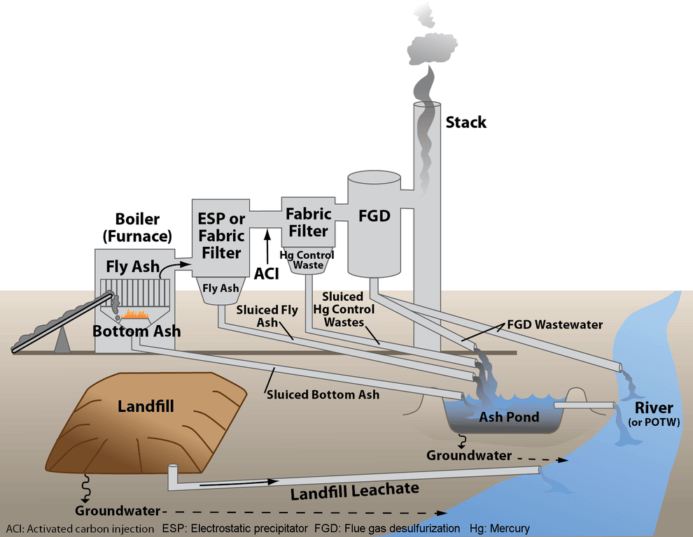

Biogas is primarily composed of methane (CH4) and carbon dioxide (CO2). It is produced in an anaerobic digester (AD) using a biological process, degrading organic matter in the absence of oxidant (e.g. oxygen). Figure 1 below is a simplified PFD of biogas production with conventional digester wastewater management.

While some of the organic matter will be broken down into biogas, digestate slurry remains. It is a mixture of solids (leftover organic matter, biomass) and wastewater in which inorganic salts are dissolved. Solids are separated and sent for disposal/used as fertilizer.

However, without further treatment, the digester wastewater cannot usually be re-used directly or discharged into a public sewer. Typical issues include total suspended solids (TSS), total dissolved solids (TDS), ammonia, biological oxygen demand (BOD), and chemical oxygen demand (COD). These characteristics of the digester wastewater are impacted by the composition of the organic matter feed, for example: municipal organic waste, livestock waste, poultry waste, manure, etc.

Digestate Wastewater Management

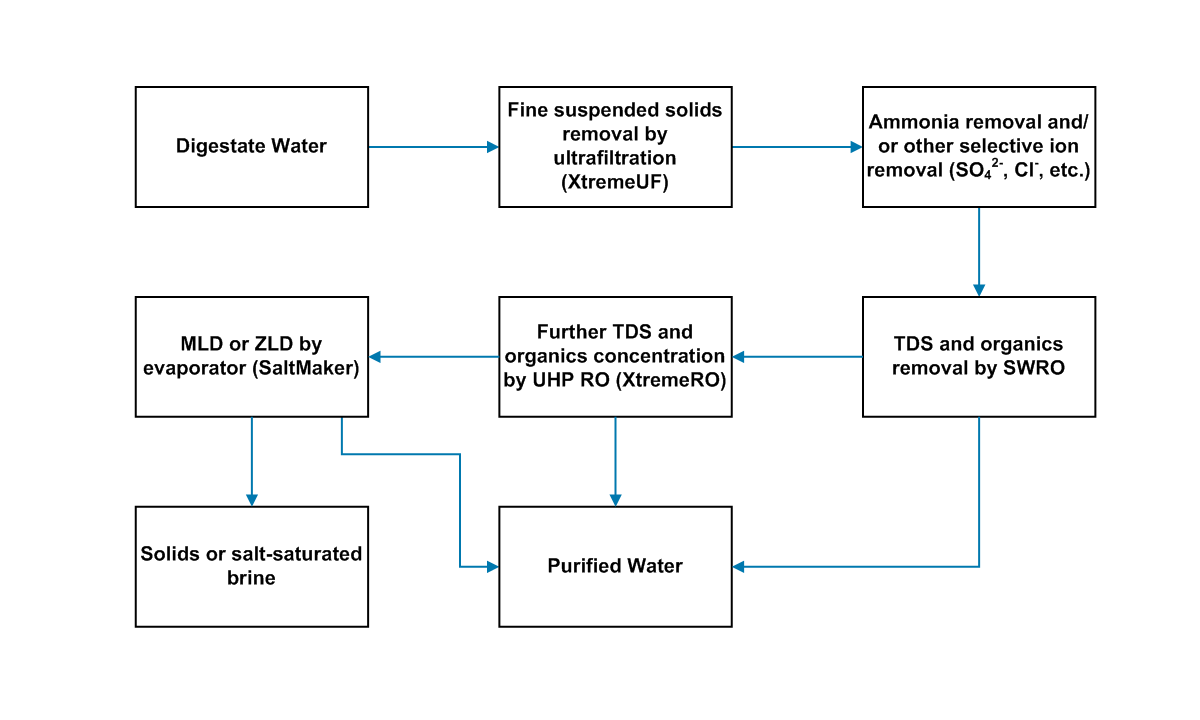

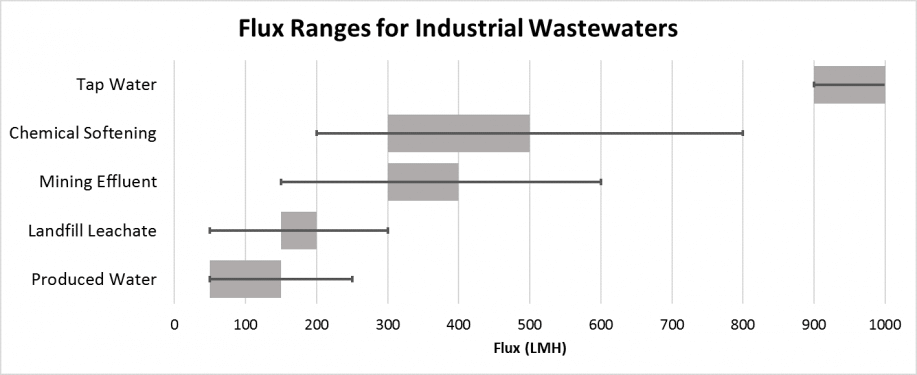

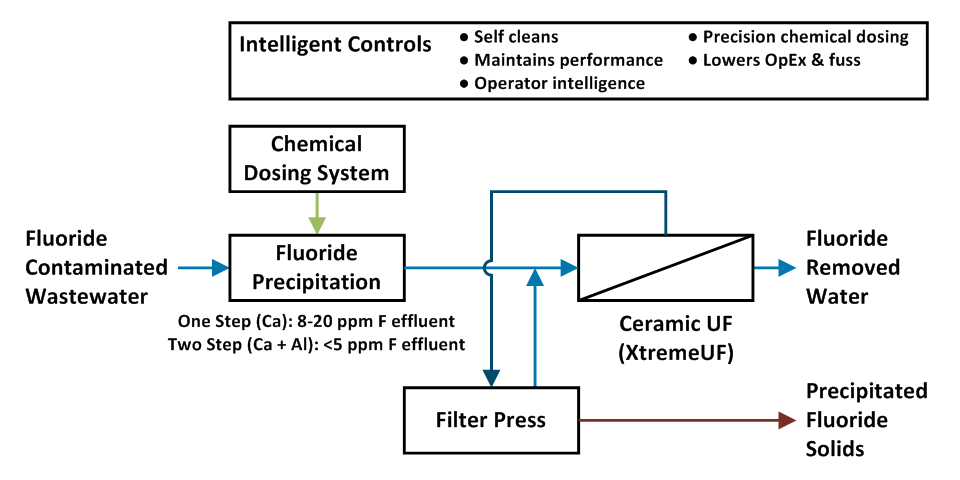

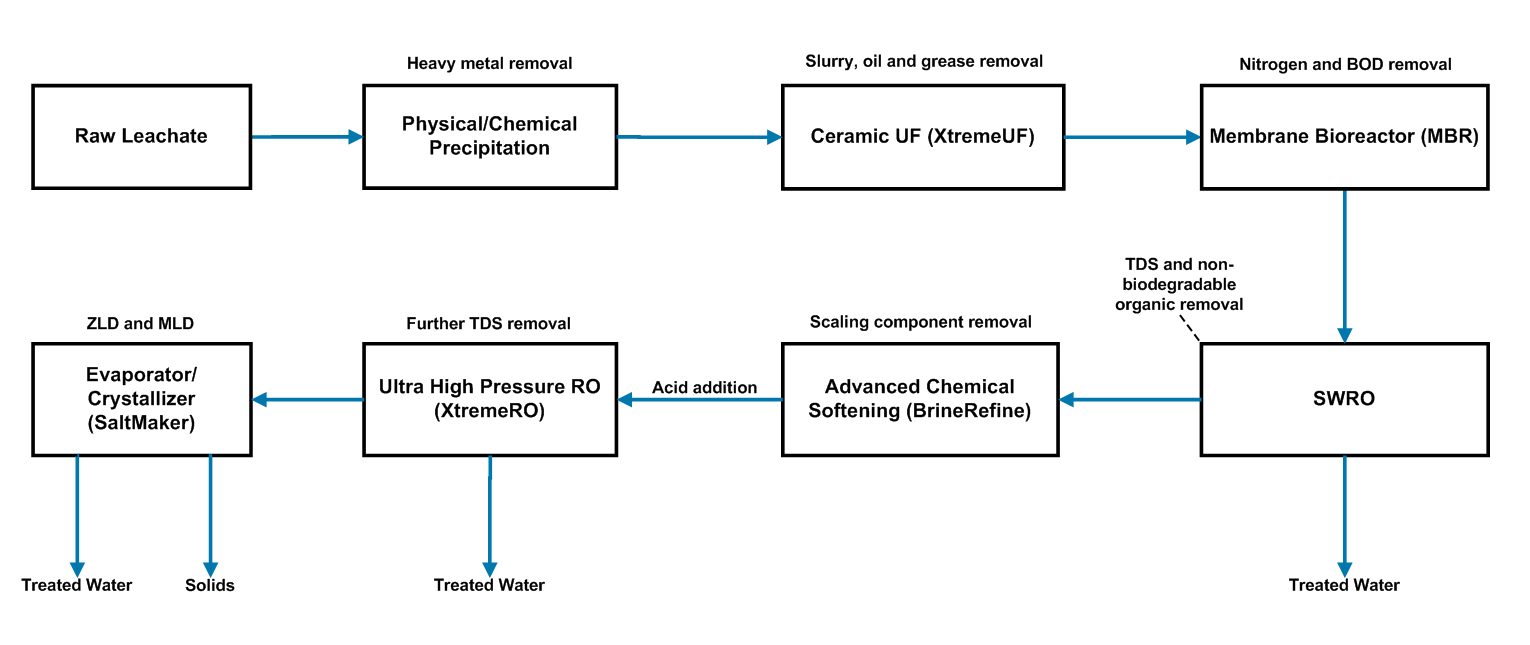

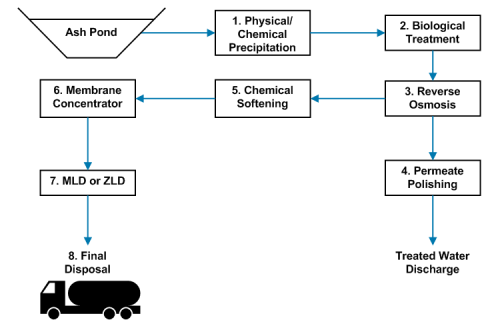

As in other wastewater treatment processes, such as for landfill leachate, digester wastewater treatment involves the application of various technologies and can range from highly targeted selective contaminant removal, up to a comprehensive ZLD process. Figure 2 shows an overview of a comprehensive treatment solution for digester wastewater, including options for zero/minimal liquid discharge (ZLD/MLD).

The most common digester wastewater constituents-of-concern are fine suspended solids, ammonia, and salt ions. However, depending on wastewater characteristics and project requirements, not all treatment steps may be needed. For example, a low-strength wastewater, with only ammonia concentrations that are beyond discharge limit compliance, will only require ammonia removal technology. To decide on an appropriate and cost-effective treatment process, it is critical to know the wastewater chemistry in detail and understand the treatment requirements. Saltworks can review water chemistry and specific project requirements so that a digester wastewater treatment process is delivered that balances simplicity, cost-effectiveness, and reliability.

Removing Suspended Solids

Suspended solids in digester wastewater pose scaling/plugging problems in any downstream equipment, especially for ammonia removal and total dissolved solids (TDS) treatments. Additionally, suspended solids make up a significant portion of BOD and COD. They can be removed from the digestate wastewater through traditional physical/chemical separation processes, namely coagulation-flocculation using ferric chloride and polymers, followed by clarification/sedimentation and media filtration of the clarifier overflow.

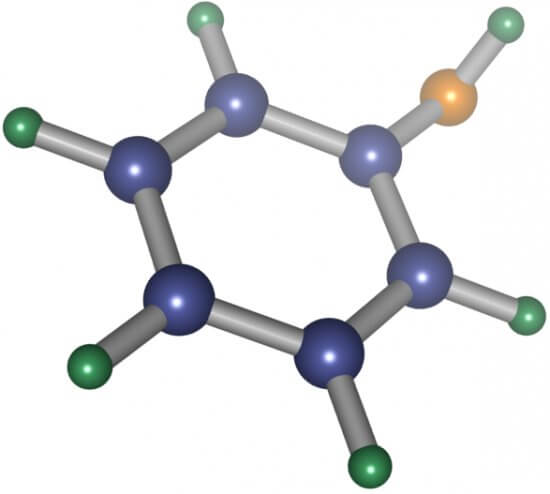

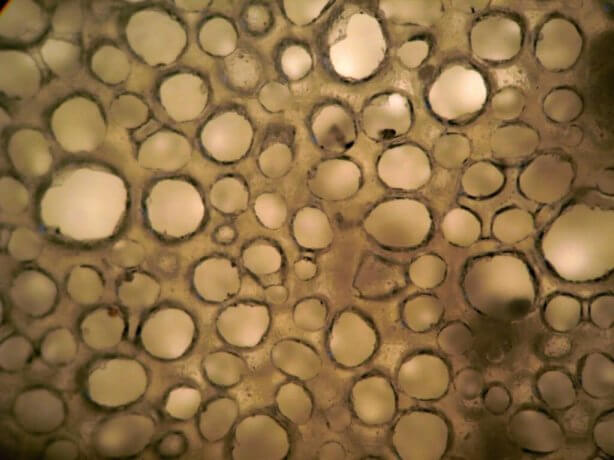

Alternatively, a more advanced membrane technology, XtremeUF, can be used to remove suspended solids in the digester wastewater without the use of coagulation-flocculation. XtremeUF, shown in Figure 3, is a ceramic-based ultrafiltration module that can concentrate suspended particulate into a dense slurry. It is highly automated, compact, and modular, offering an alternative to traditional physical/chemical separation processes for projects requiring low footprint, low maintenance, and process simplicity. One of our other articles has a more detailed explanation on ceramic ultrafiltration.

Ammonia Removal

The selection of an appropriate ammonia removal method depends on the concentration, the presence of other contaminants (e.g. bicarbonate, phosphate, organics, and metal ions), local conditions, energy sources, and the economic usability of the end-product (i.e. can it be re-used as a fertilizer). An overview of these ammonia removal options is provided in Table 1, below.

Table 1. A comparison of ammonia removal solutions.

| Technology | Process Description | Considerations & Applicability |

|---|---|---|

| Air Stripping |

|

|

| Steam Stripping |

|

|

| Biological Nitrification-Denitrification |

|

|

| Anammox |

|

|

| Breakpoint Chlorination |

|

|

| Struvite Precipitation |

|

|

Total Dissolved Solids (TDS) Removal Through Reverse Osmosis and Evaporation

The most common TDS removal technologies are reverse osmosis (RO) and evaporators. Due to wide availability, low cost, and energy efficiency, RO is typically recommended upstream of evaporators. You can read more about how reverse osmosis can decrease treatment costs.

Digester wastewater enters a seawater reverse osmosis (SWRO) system for further removal of TDS and organics. The SWRO operates at pressures of up to 1,200 psi, producing a brine stream with around 70,000 mg/L TDS and a high-quality permeate water stream. In a typical biogas plant, the SWRO operates at 80% permeate recovery. The permeate can be re-used within the biogas plant or be safely discharged. The SWRO-brine can be disposed of in the compositing process of digestate solids waste, or in a disposal well, depending on which option the economics favor.

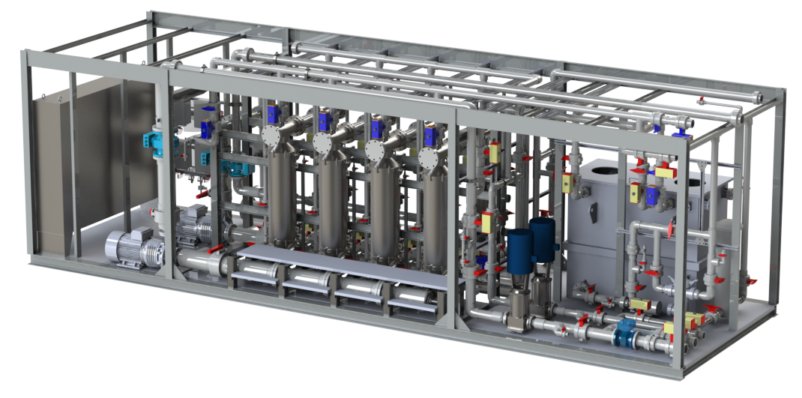

If MLD/ZLD is required, the SWRO brine can be further treated in an ultra-high pressure reverse osmosis system, such as our XtremeRO system, shown in Figure 5. XtremeRO uses spiral wound RO membranes that allow operation of up to 1,800 psi and can further concentrate the SWRO brine up to a TDS of about 140,000 mg/L in some conditions. Compared to existing thermal evaporation technology, XtremeRO is about 3× more energy efficient for decreasing brine volume, providing a significant decrease in the energy cost of a downstream evaporation system. Saltworks’ intelligent automation for SWRO and XtremeRO makes them especially well-suited for the treatment of digester wastewater. Flux monitoring and automated self-cleaning ensure that the membranes remain free of organic fouling.

To achieve ZLD, XtremeRO brine is then treated by a thermal evaporation system. Many options exist for evaporator systems, such as Saltworks’ SaltMaker AirBreather and MultiEffect products, shown in Figure 6. The distillate from the evaporator crystallizer will be high quality and can be discharged or re-used within the biogas plant. All contaminants will be reduced to minimal liquid volume or solids for final disposal or land application.

Contact Us

If you have wastewater needs downstream of an anaerobic digester, contact us. Our process engineering experts will provide options analysis, taking your treatment goals and economics into account.

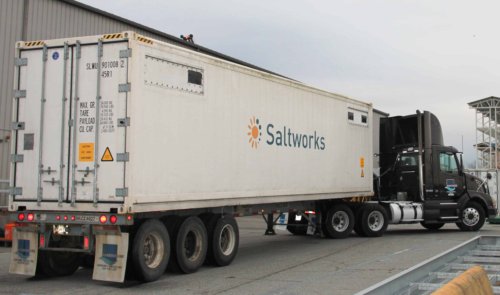

About Saltworks

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Related Resources

Ammonia Wastewater Treatment

There is no one-size-fits-all solution to removing ammonia from wastewater. Saltworks can help you understand your options, including hybridizing solutions with biological treatments to boost capacity and reliability, or provide entirely non-biological pathways.

Ultra High Pressure Reverse Osmosis for Landfill Leachate

Reverse osmosis (RO) is the best available technology to treat landfill leachate for surface discharge. Possible trace volatile organic compounds (VOCs) and ammonia emerging in the RO permeate can be removed with a polishing step to meet the highest discharge standards.

Zero Liquid Discharge (ZLD) and Minimal Liquid Discharge (MLD) Become Lower Cost Through Reverse Osmosis Innovation

Saltworks is pleased to announce that recent advancements in reverse osmosis technology are now commercially available. Reduce conventional RO brine volumes by 50%, achieving brine concentrations of 130,000 to 150,000 mg/L TDS with spiral wound RO membranes.

Introducing AirBreather: A Lower Cost Evaporator

A low-cost and air-safe evaporator crystallizer has been developed: the SaltMaker AirBreather. It is based on the robust backbone of Saltworks’ SaltMaker Family.